Halogen-free flame-retardant polyolefin sheath material and preparation method thereof

A polyolefin sheath, polyolefin elastomer technology, applied in plastic/resin/wax insulators, organic insulators, electrical components, etc. Effects of smoke generation rate, mass loss suppression, risk and toxicity suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

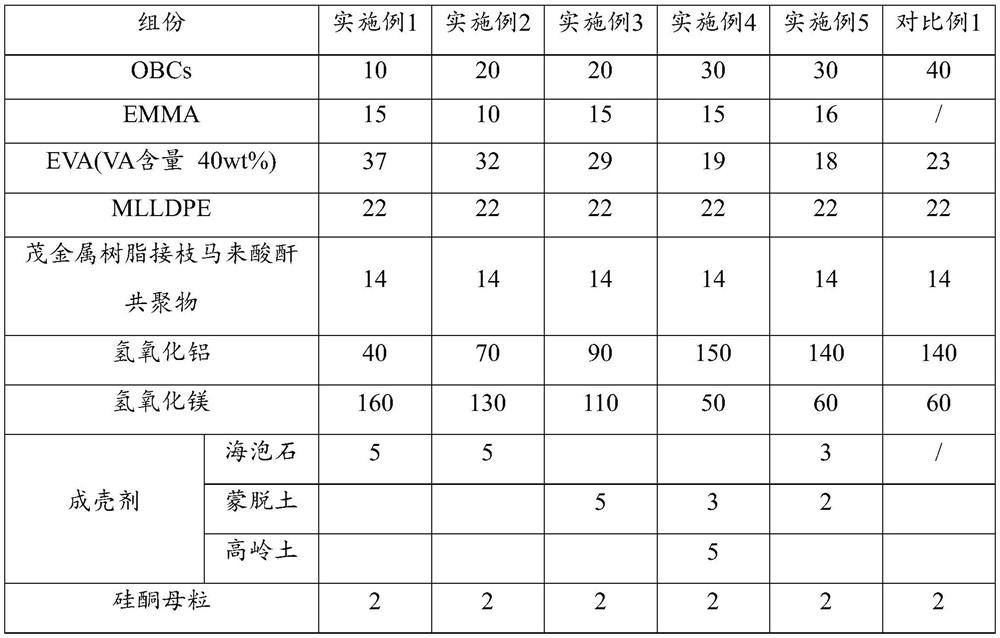

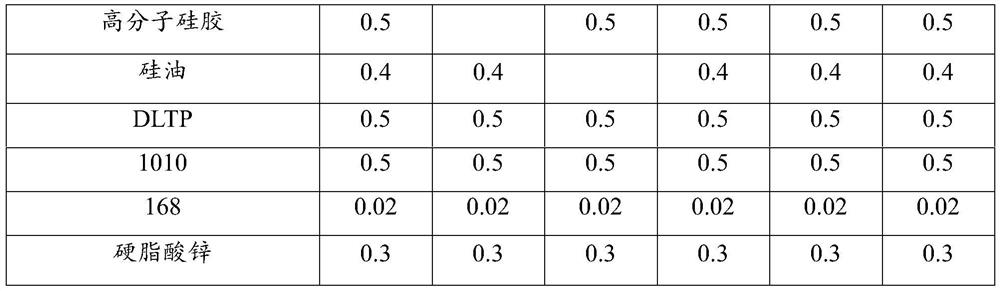

Examples

Embodiment 1

[0034] Mix 40 parts of aluminum hydroxide, 160 parts of magnesium hydroxide and 5 parts of nucleating agent sepiolite at high speed, the high-speed mixing time is 5min-10min, the speed of the high-speed mixer is 250rpm-500rpm, and then add Mix 0.4 parts of silicone oil, 2 parts of silicone masterbatch, and 0.5 parts of high molecular weight silica gel at high speed for 10 minutes to obtain a compound flame retardant;

[0035]10 parts of OBCs, 15 parts of EMMA, 37 parts of EVA with VA content of 40wt%, 22 parts of MLLDPE, 14 parts of modified compatibilizer metallocene resin grafted maleic anhydride copolymer, 2 parts of silicone masterbatch, 0.5 parts of high Molecular silica gel, 0.4 part of silicone oil, 0.5 part of DLTP, 0.5 part of 1010, 0.02 part of 168 and 0.3 part of zinc stearate are internally mixed with a 75L internal mixer. The internal mixing temperature of the internal mixer is 150-160°C, and SDJ75-180 is used. Twin-screw / single-screw unit mixing, plasticizing, gr...

Embodiment 2-5

[0038] The preparation method of Example 2-5 is basically the same as that of Example 1, the only difference is that: The composition and content of the flame-retardant polyethylene sheath material in Example 2-5 is different from that of Example 1 flame-retardant polyethylene The components and contents of the sheathing material are shown in Table 1 in Examples 2-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com