Trough tank structure for producing composite material

A composite material and trough technology, applied in the field of troughs and tanks, can solve the problems of incomplete discharge, difficult cleaning, and actual discharge of stored materials, so as to reduce labor intensity, improve cleaning difficulties, and ensure the effect of thoroughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] To make the object, technical solution and advantages of embodiments of the present invention more clear, the following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention are clearly and completely described, obviously, the embodiments described are part of the embodiments of the present invention, not all embodiments. Typically described and illustrated herein in the drawings and the components of the embodiments of the present invention may be arranged and designed in various different configurations.

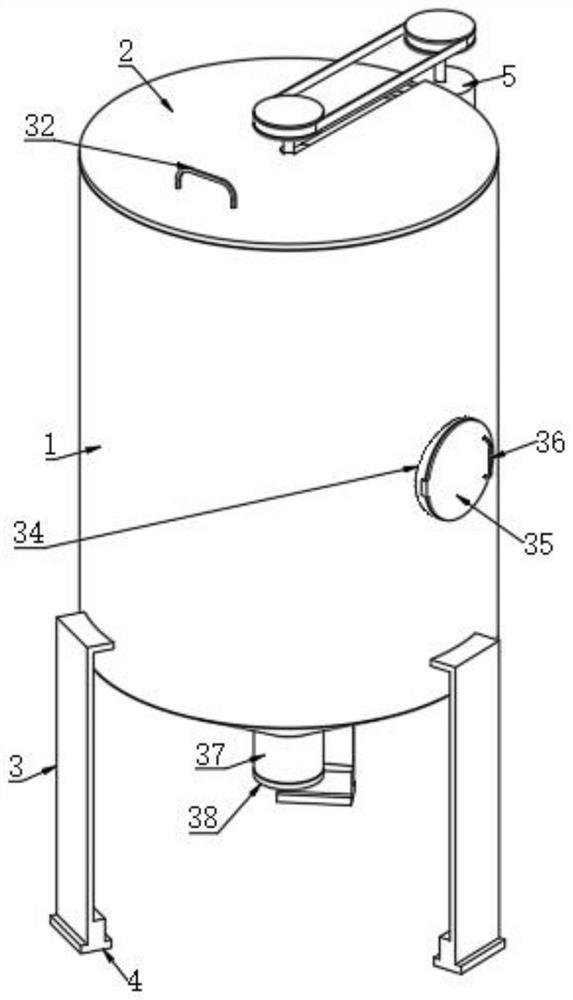

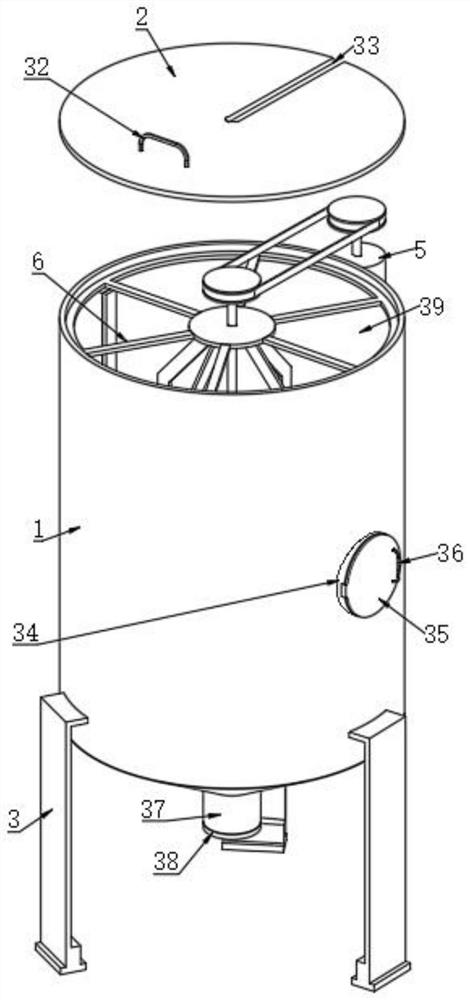

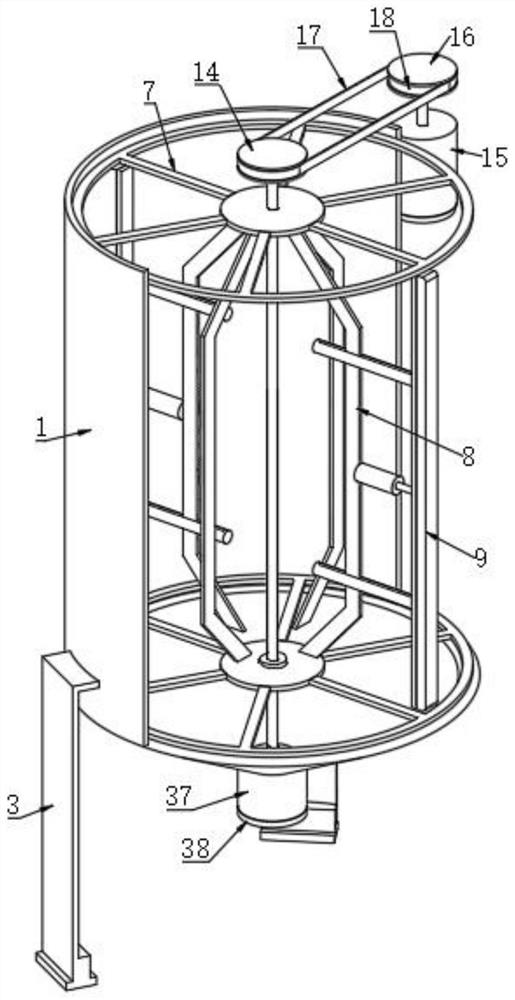

[0033] as Figures 1 through 8 As shown, a kind of tank structure for the production of composite materials, comprising the tank tank body 1, the internal of the tank body 1 is provided with an anti-plugging device 6, the anti-plugging device 6 includes a rotating component 7 and a pulling arm 8, the lower part of the rotating assembly 7 is provided with a padding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com