Method for preventing surface cracking in austenitic stainless steel forge piece manufacturing process

A technology of austenitic stainless steel and manufacturing process, which is applied in the field of steel processing and forging, which can solve the problems of high manufacturing cost, scratch cleaning, and long forging manufacturing cycle, and achieve the effect of low difficulty, less shrinkage cavity and looseness, and fast solidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

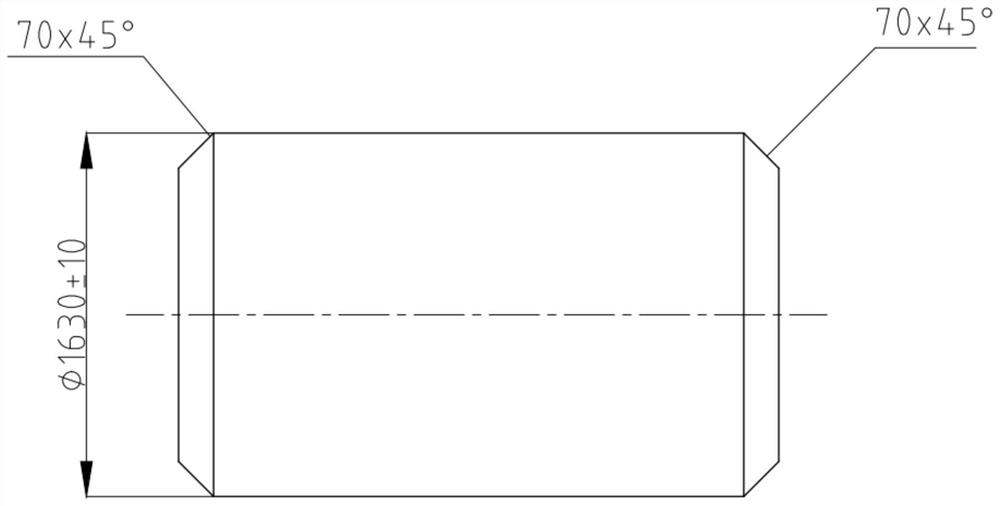

[0031] The applicant took the 304 material φ6879xφ6379x222mm top support forging ring ordered by a customer as an example. The weight of the forging ring blank: 14.8 tons, and the blanking weight was 16.7 tons.

[0032] Implementation of the present invention comprises the following steps:

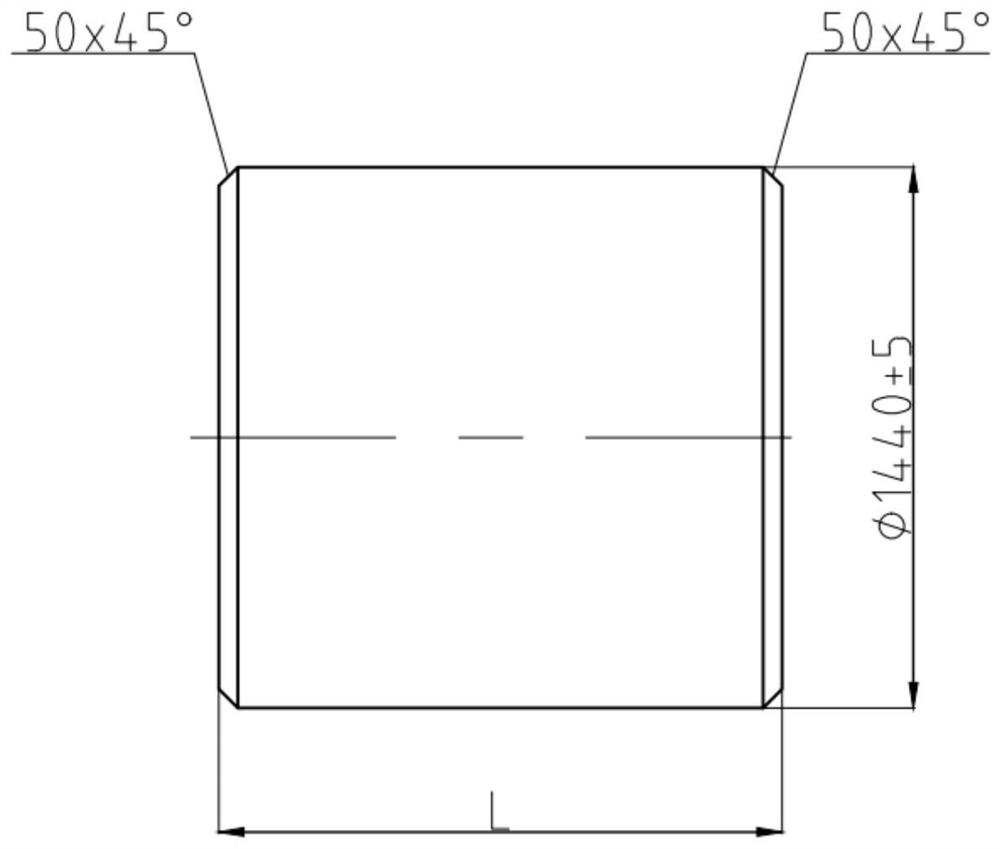

[0033] (1) Slab sawing: After the slabs pass the re-inspection after entering the factory, they are sawed and cut into 9 small unit slabs with a size (length×width×height) of 1230x1120x200mm;

[0034] (2) Heat treatment of slab: solution treatment, heating temperature is 1060℃±10℃;

[0035] (3) Milling: small unit slab milling 6 faces, the size is (length × width × height) 1220x1110x193mm, the roughness of the upper and lower sides is Ra6.3, and the rest of the surface is Ra12.5;

[0036] (4) Cleaning and grinding, the cleanliness of the upper and lower surfaces of each blank RFU=5;

[0037] (5) Blank assembly: the slab is assembled on the platform in advance, and the time for the whole ...

Embodiment 2

[0052] The applicant undertakes a nuclear power project ring of φ4825xφ3930x185mm in F316H material ordered by a customer as an example. The weight of the forging ring blank is 22 tons, and the blanking weight is 26.5 tons.

[0053] Implementation of the present invention comprises the following steps:

[0054] (1) Slab sawing: the size of the slab is 9210mm×1545mm×200mm, and after passing the re-inspection at the factory, it is sawed and cut into 10 small unit slabs with a size (length×width×height) of 1545×1150×200mm.

[0055] (2) Slab heat treatment: solution treatment first, the heating temperature is 1060°C ± 10°C.

[0056] (3) Milling: small unit slab milling 6 faces, the size is (length x width x height) 1530x1130x193mm, the roughness of the upper and lower sides is Ra6.3, and the rest of the face is Ra12.5.

[0057] (4) Cleaning and grinding, the cleanliness of the upper and lower surfaces of each billet is RFU=6.

[0058] (5) Blank assembly: the slab is assembled on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com