Forming method of hourglass-shaped metal structure

An hourglass-shaped, metal technology, applied in the field of metal material manufacturing, can solve problems such as weld cracking and tensile stress, and achieve the effects of low difficulty, less shrinkage porosity, and densified manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

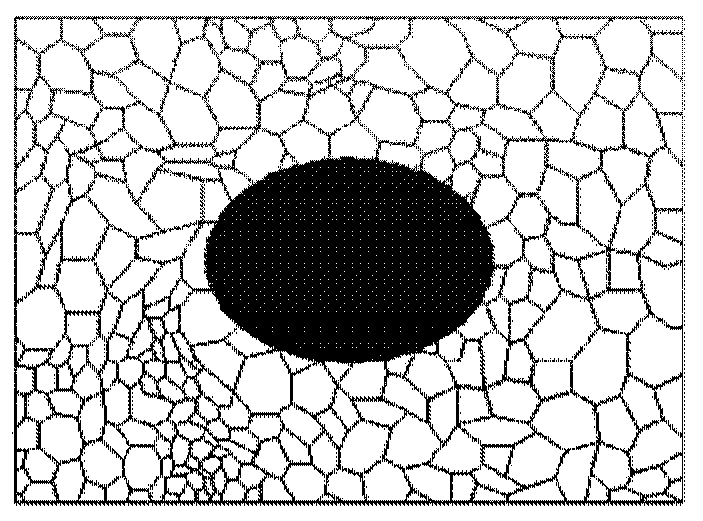

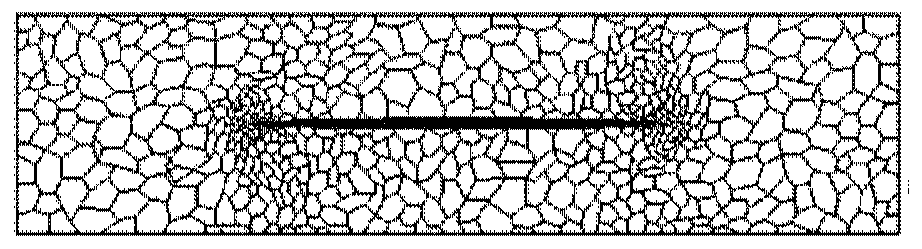

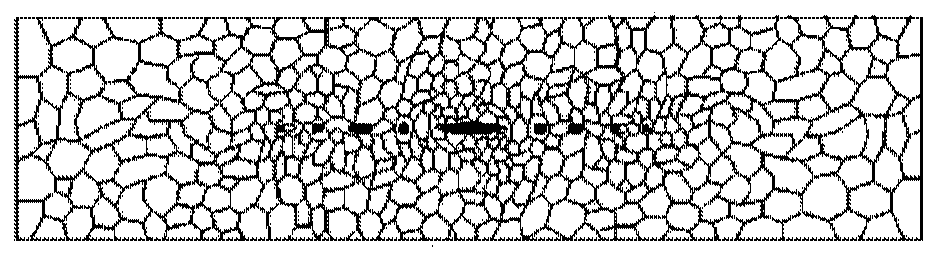

Image

Examples

Embodiment 1

[0055] The target product of this embodiment is a module. Firstly, the continuous casting method is adopted, and the continuous casting slab with a thickness of 200mm is poured. Afterwards, the continuous casting slab is forged and processed into the required truncated cone shape as required. Vacuum electron beam welding is performed after the surface of the forging element is processed and cleaned. Finally, forging and machining are carried out. Specific steps are as follows:

[0056] The first step is to forge and process the continuous casting billet according to certain specifications. The required blanks are 11 pieces, which are forged to the required size. According to the stacking sequence, the diameter of the billet gradually decreases from both ends to the middle, and the side slope angle is 15°. The uppermost and lowermost blanks have a large plane of φ1.5m and a small plane of φ1.393m. The big plane of the last and next next piece of billet is φ1.393m, the sma...

Embodiment 2

[0066] The target product of this embodiment is a module. Firstly, the continuous casting method is adopted, and the continuous casting slab with a thickness of 200mm is poured. Afterwards, the continuous casting slab is forged and processed into the required truncated cone shape as required. After processing and cleaning the surface of the forging element, seal the box and vacuumize it. Finally, forging and machining are carried out. Specific steps are as follows:

[0067] The first step is to forge and process the continuous casting billet according to certain specifications. The required blanks are 12 pieces, which are forged to the required size. According to the stacking sequence, the diameter of the billet gradually decreases from both ends to the middle, and the side slope angle is 15°. The uppermost and lowermost blanks have a large plane of φ1.5m and a small plane of φ1.393m. The big plane of the last and next next piece of billet is φ1.393m, the small plane is ...

Embodiment 3

[0077] The target product of this embodiment is a module. Firstly, the continuous casting method is used to cast Q235 continuous casting slabs with a width of 1500mm and a thickness of 200mm. Afterwards, the continuous casting slab is processed into the desired trapezoidal shape as required. After processing and cleaning the surface of the continuous casting slab element, vacuum electron beam welding is carried out. Finally, forging and machining are carried out. Specific steps are as follows:

[0078] The first step is to cut and process the continuous casting slab according to certain specifications. The required blanks are 11 pieces, which are cut and processed to the required size. According to the stacking sequence, the diameter of the billet gradually decreases from both ends to the middle, and the side slope angle is 15°. The large plane of the uppermost and the lowermost blank is 1.5m×1.5m, and the small plane is 1.393m×1.393m. The big plane of the upper and next...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com