Welding method for air exhaust adapter and air exhaust pipe of miniature fission chamber

A welding method and fission chamber technology are applied in the field of welding of micro-fission chamber air extraction adapters and air extraction pipes, which can solve the problems of easy welding penetration, limited welding space, and sealing failure, etc. Ensuring high-quality assembly and stable welding depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

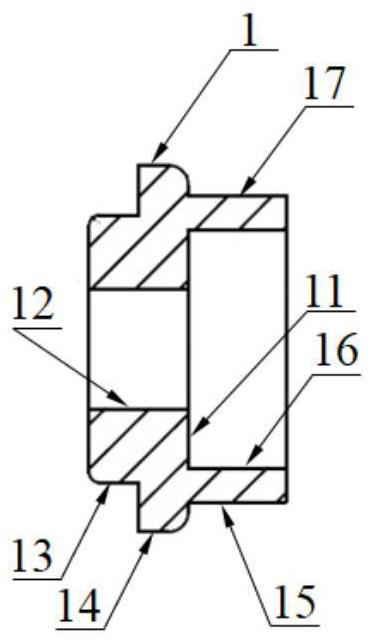

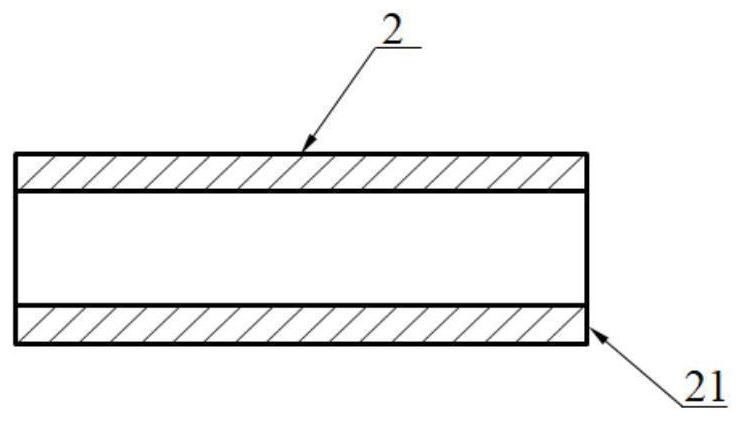

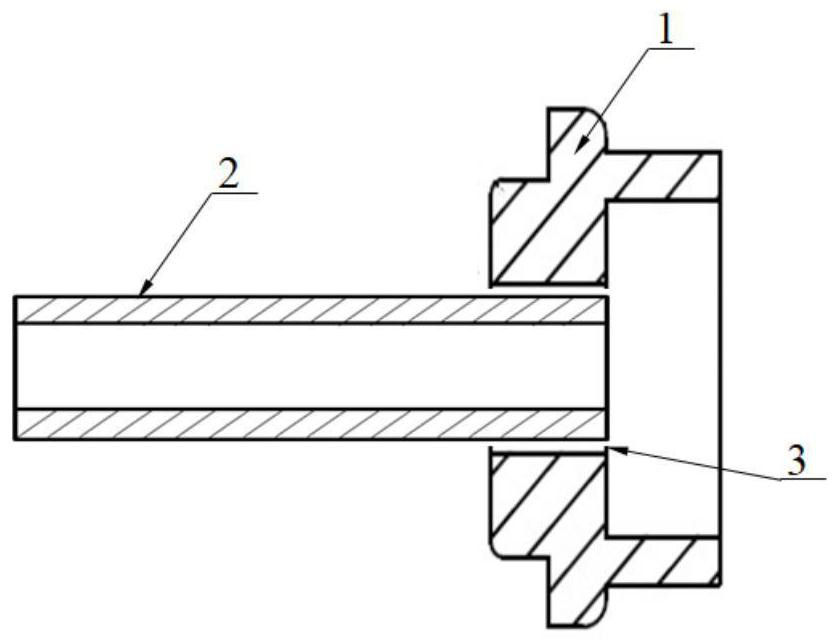

[0024] figure 1 and figure 2 The pumping adapter and the pumping tube used in the micro-fission chamber neutron detector of the CPR1000 reactor are shown respectively. Among them, the suction adapter 1 is a stepped rotary part, and its size is small. The specific parameters are: the maximum outer diameter is 3.7mm at the second outer surface 14 of the suction adapter, and the minimum outer diameter is located at the second outer surface of the suction adapter. The first outer surface 13 is 2.7 mm, the outer diameter of the third outer surface 15 of the air extraction adapter is 3.1 mm, the inner diameter of the first inner surface 12 of the air extraction adapter is 1.2 mm, and the second inner surface 16 of the air extraction adapter The inner diameter is 2.4 mm, the axial thickness of the first outer surface 13 of the air extraction adapter and the second outer surface 14 of the air extraction adapter are both 0.5 mm, and the overall axial thickness of the air extraction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com