Stopper rod flow control system control method for improving stability of liquid level of crystallizer

A control method and crystallizer technology, which are applied in the direction of manufacturing tools, casting melt containers, casting equipment, etc., to achieve the effects of reducing the size of liquid level fluctuations, the incidence of slag inclusion defects and surface cracks, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

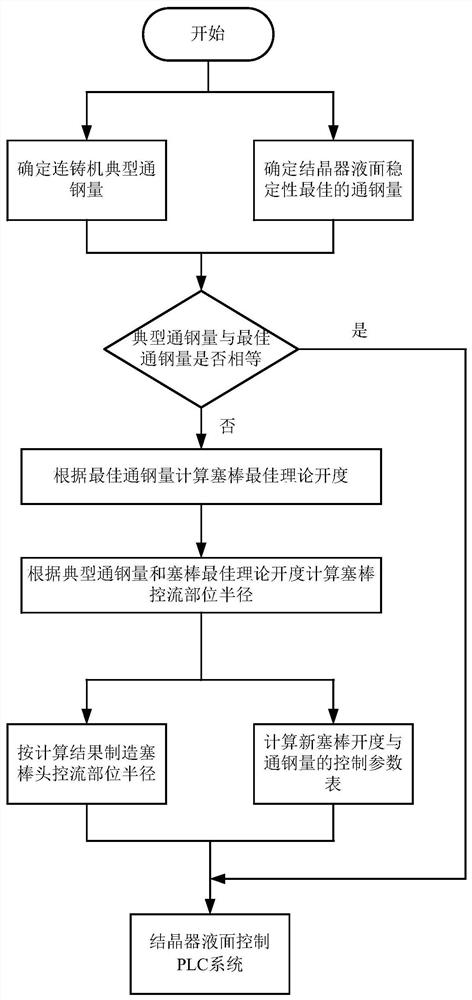

[0043] Embodiment 1: see figure 1 , a control method of a stopper flow control system for improving the stability of the crystallizer liquid level, the control method comprising the following steps:

[0044] Step 1: Determination of the typical steel flow of submerged nozzles in the actual production process;

[0045] Theoretically, the determination of the typical steel flow of submerged nozzles in the actual production process is usually calculated by the estimated steel production volume and pouring cycle, but in the actual production process, the steel production volume and pouring cycle are quite different from the design. In order to obtain accurate steel production volume and pouring cycle, the present invention obtains the ratio arrangement diagram of the steel flow ratio through big data analysis on the steel flow rate of the nozzle in the actual production process, and takes the steel flow rate with the highest proportion as a typical steel flow rate. quantity.

...

specific Embodiment

[0071] Specific embodiment: a control method of a stopper rod flow control system that improves the stability of the crystallizer liquid level, the control method includes the following steps:

[0072] It is aimed at slabs under casting conditions with a casting speed ranging from 0.8 to 1.8m / min (the cross section of the crystallizer is 230×900 to 1650mm 2 ).

[0073] Step 1: Determine the typical steel flow of the submerged nozzle;

[0074] The amount of steel passing through the nozzle = the nominal width of the slab × the nominal thickness of the slab × the density of the slab × the casting speed of the continuous casting machine Formula (1)

[0075] Typical steel volume (Q typ ) = MAX{annual steel flow ratio i}, where i is a natural number that is generally a multiple of 0.5t / min steel flow. Formula (2)

[0076] Table 1 Distribution of main steel grades and steel quantities in a factory

[0077] Through steel quantity, t / min 1.0 1.5 2.0 2.5 3.0 3.5 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com