Integrated device and manufacturing method of electrostatic chuck

An electrostatic chuck and integrated device technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problem of affecting the temperature uniformity of electrostatic chucks, not mentioning large-area bonding, and inconsistency in edge and internal thermal conductivity and other problems, to achieve the effect of good defect control, high bonding strength and consistent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

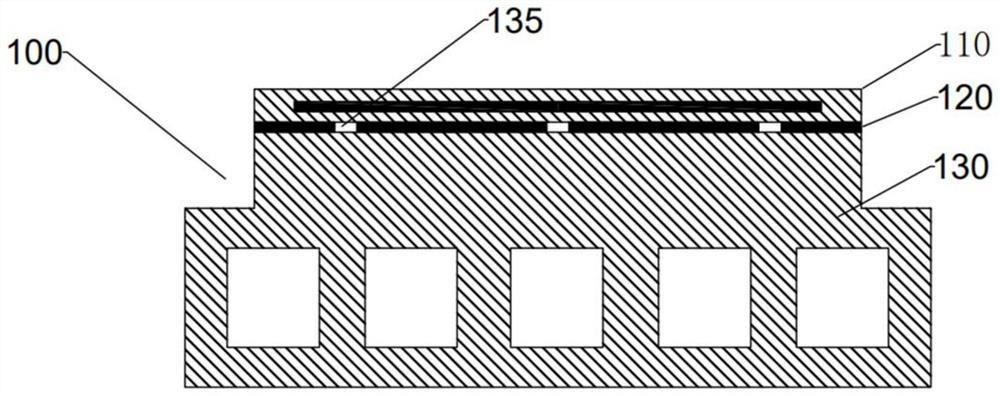

[0055] Such as figure 1 As shown, a normal temperature electrostatic chuck 100 generally does not require a heater and contains an adhesive layer. Wherein, 110 is a ceramic layer, 120 is an adhesive layer, and 130 is a metal base with a cooling function. The adhesive layer 120 is provided with at least one evenly distributed blocks 135 of equal height.

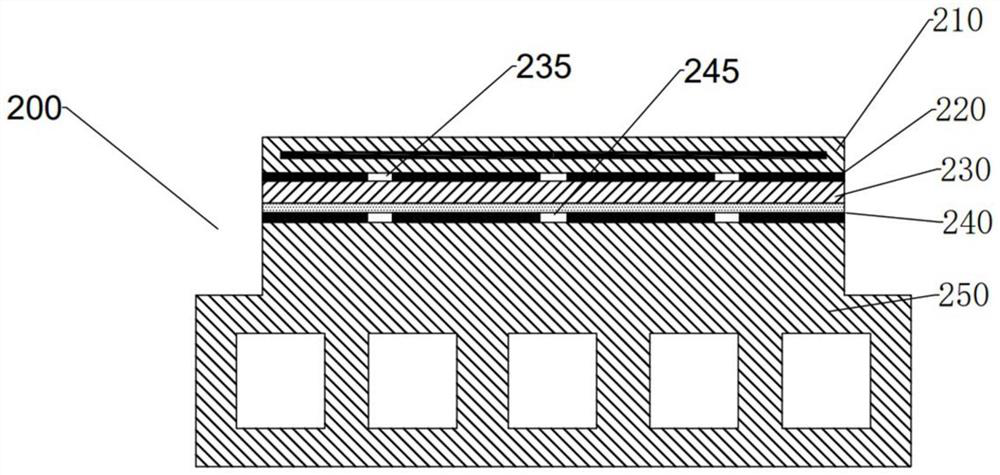

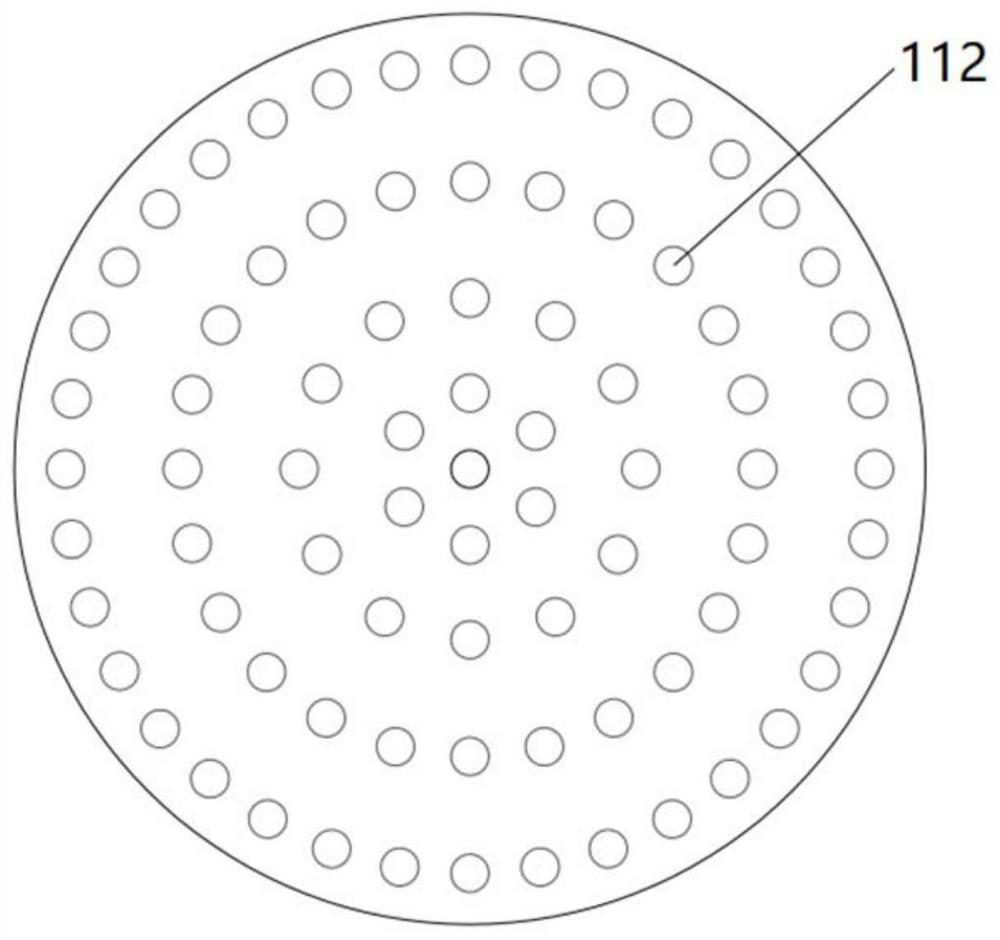

[0056] Such as figure 2 As shown, a variable temperature electrostatic chuck 200, from top to bottom is a ceramic layer 210, a first adhesive layer 220, a heater 230, and a second adhesive layer 240, 250 is a metal base. The first adhesive layer 220 is provided with at least one evenly distributed first equal-height block 235, and the second adhesive layer 240 is provided with at least one evenly distributed second equal-height block 245, such as image 3 shown.

[0057] The adhesives involved in the above electrostatic chucks are elastic adhesives, such as silica gel and silicone rubber, but are not limited to these. The...

Embodiment 2

[0064] Such as Figure 4 As shown, an integrated device 400 of an electrostatic chuck includes a vacuum chamber and a vacuum system, and the vacuum chamber includes an upper chamber 410 and a lower chamber 420 separated by a partition; the vacuum system and The upper chamber 410 and the lower chamber 420 are connected; the upper chamber 410 and the lower chamber 420 are separated by a partition, and the contact positions between the upper and lower chambers and the partition are sealed by a sealing ring 415 .

[0065] The electrostatic chuck 100 or 200 in Embodiment 1 can be positioned in the lower chamber 420 for integration, and the upper chamber 410 is inflated to apply pressure to the electrostatic chuck 100 or 200 through deformation of the partition.

[0066] The upper chamber 410 and the lower chamber 420 may optionally be evacuated or at atmospheric pressure.

[0067] The vacuum pumping system includes a first vacuum pump pipeline 434, a second vacuum pump pipeline 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com