Polycrystalline crystal plasticity constitutive parameter rapid calibration method

A technology of crystal plasticity and parameter calibration, applied in the fields of chemical property prediction, instrumentation, computer material science, etc., can solve the problems of long cycle, increased calculation amount, large calculation consumption of optimization tools, etc., to achieve rapid calibration, shorten optimization cycle, reduce Quantity and effect of calculating consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

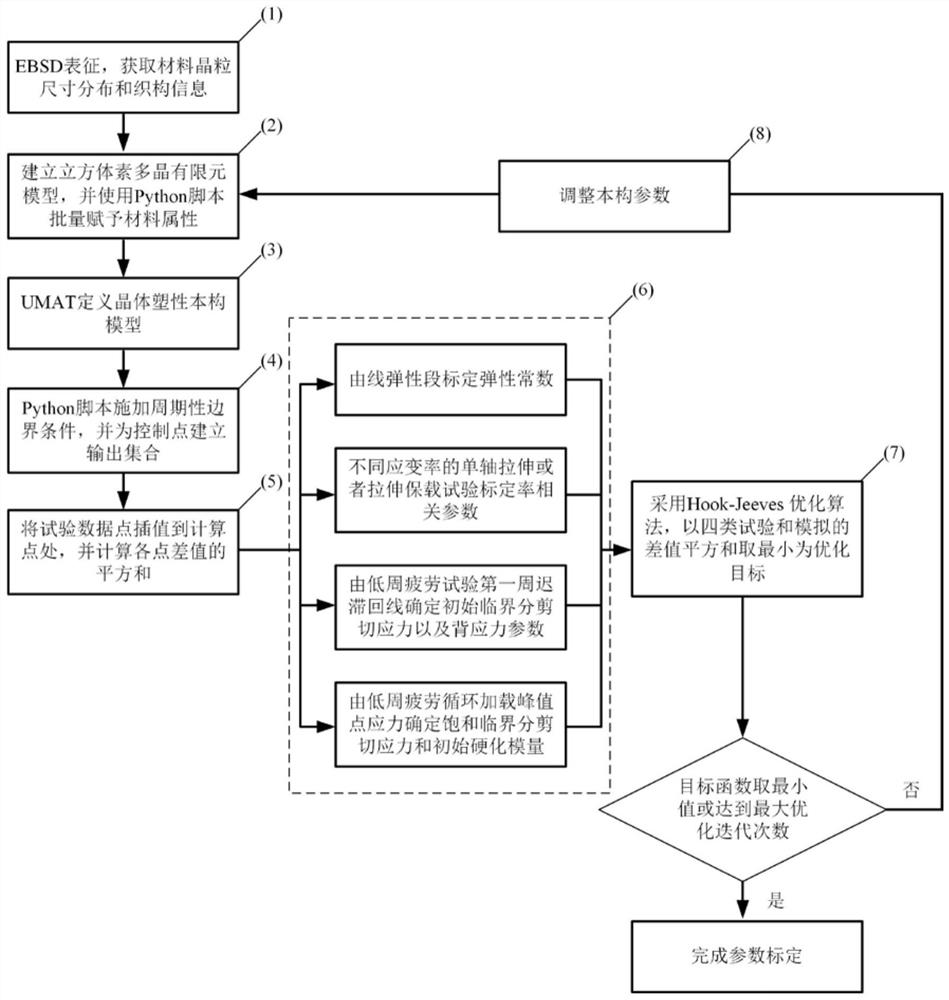

[0035] The implementation flow chart of a method for fast calibration of polycrystalline plastic constitutive model parameters of the present invention is as follows figure 1 shown, including the following steps:

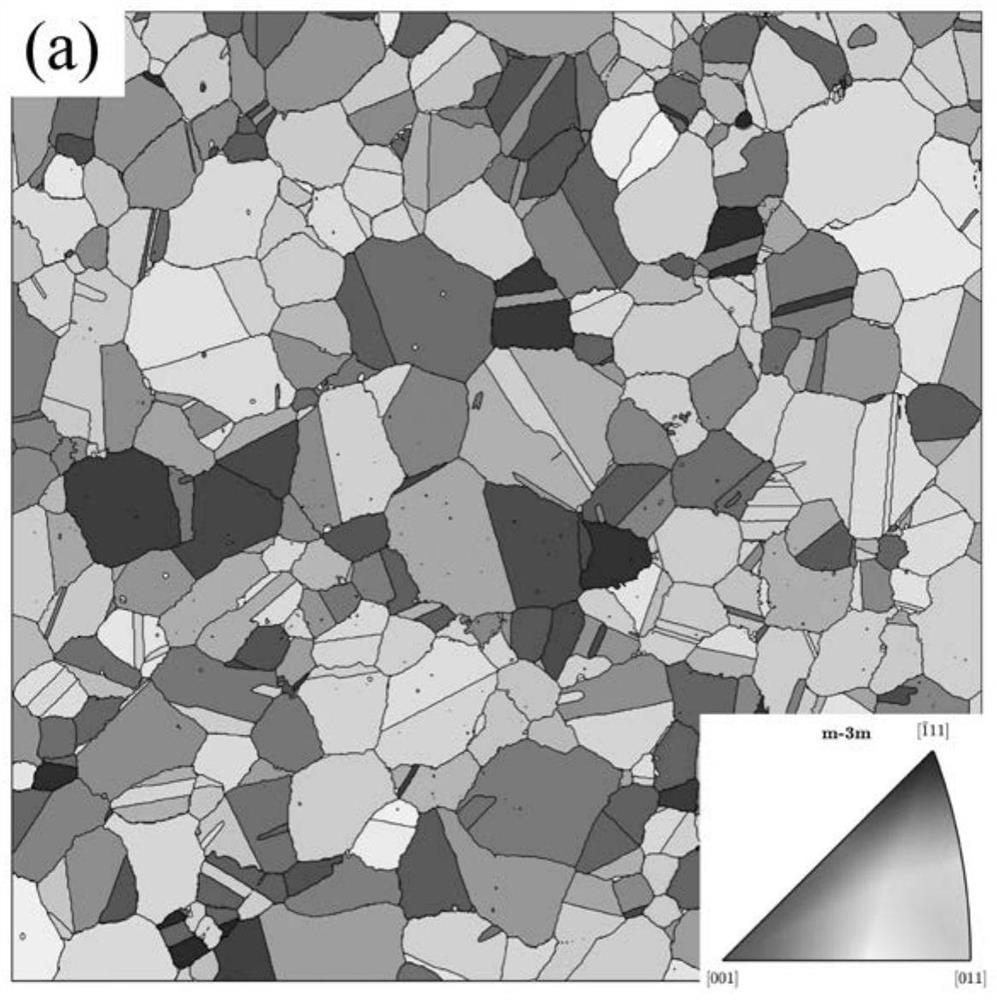

[0036] (1) For a certain type of nickel-based alloy material, a cylindrical metallographic sample with a diameter of 6 mm and a height of 3 mm is cut from the center of the disc-shaped billet with a uniform structure, sanded and SiO 2 After polishing with the polishing solution, the grain boundaries were etched out using Kailing reagent, and observed with a light microscope to preliminarily estimate the grain size. According to the measured grain size, select a scan step size of 1 / 20 of the average grain size and a scan area of 400μm*400μm for EBSD characterization to include enough grain numbers to obtain the statistical distribution of grain size and texture characteristics ,like Figure 2a and Figure 2b shown.

[0037] (2) Establish a total of 512 cubic po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com