Liquid lens optical system and camera lens

A liquid lens and optical system technology, applied in the field of lenses, can solve the problems affecting user experience, insufficient focusing clarity, narrow working distance range, etc., achieve fast auto focus, wide working distance range, and improve production yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

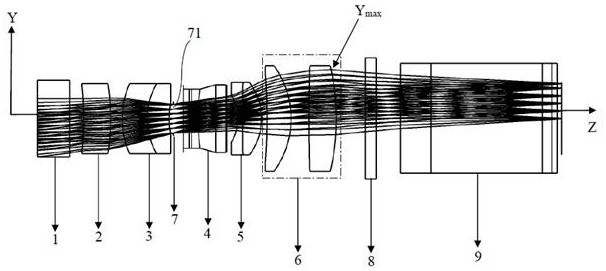

[0063] like Figure 1 to Figure 4 As shown, the liquid lens optical system provided by the first embodiment of the present invention includes a first lens group 2, a second lens group 3, a liquid lens 4, and a third lens group that are sequentially arranged along the optical axis from the object plane to the image plane 5. The fourth lens group 6 , the filter 8 and the prism unit 9 .

[0064] The first lens group 2 is a single lens, the surface of the first lens group 2 facing the object plane is concave, the surface of the first lens group 2 facing the image plane is convex, and the first lens group 2 has a positive optical focus degrees, its focal length is about 62mm.

[0065] The second lens group 3 is a doublet lens, the surface of the second lens group 3 facing the object plane is convex, the surface of the second lens group 3 facing the image plane is concave, and the second lens group 3 has a positive refractive power , its focal length is about 172mm.

[0066]The w...

no. 2 example

[0074] like Figure 5 to Figure 8 As shown, the liquid lens optical system provided by the second embodiment of the present invention includes a first lens group 2, a second lens group 3, a liquid lens 4, and a third lens group sequentially arranged along the optical axis from the object plane to the image plane 5. The fourth lens group 6 , the filter 8 and the prism unit 9 .

[0075] The first lens group 2 is a doublet lens, the surface of the first lens group 2 facing the object plane is concave, the surface of the first lens group 2 facing the image plane is convex, and the first lens group 2 has positive light power, its focal length is about 50mm.

[0076] The second lens group 3 is a single lens, the surface of the second lens group 3 facing the object plane is convex, the surface of the second lens group 3 facing the image plane is concave, and the second lens group 3 has positive refractive power, Its focal length is about 20mm.

[0077] The working voltage of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com