Heat exchange tube

A technology of heat exchange tubes and casings, which is applied in the direction of heat exchange equipment safety devices, tubular elements, heat exchange equipment, etc., can solve the problem of low input-output ratio, heat exchange tube vibration, and inability to use heat exchange efficiency metal heat exchangers and other problems to achieve the effect of solving the vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

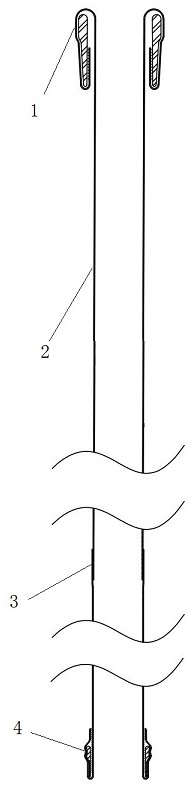

[0027] like figure 1 As shown, a heat exchange tube includes a pressure head section 1, a heat exchange section 2, a connecting section 3 and an anti-vibration section 4 from top to bottom.

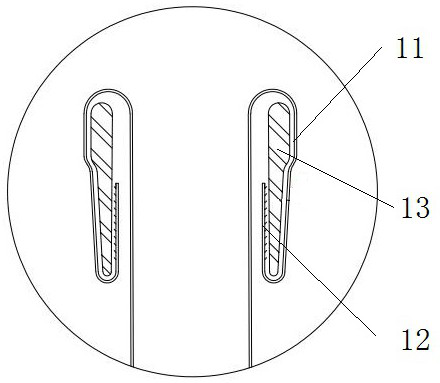

[0028] like figure 2 As shown, the pressure head section 1 is arranged on the outside of the heat exchange tube, and includes a first folded edge 11 , a second folded edge 12 and a pressure head metal 13 . The top end of the first folded edge 11 is connected with the top end of the heat exchange tube in an arc, and the included angle with the tube wall of the heat exchange tube is not less than 180°. The design of this folded edge can effectively prevent tearing. The second folded edge 12 is arranged between the tube wall of the heat exchange tube and the first folded edge 11, and its bottom end is arc-connected with the bottom end of the first folded edge 11, and the included angle with the first folded edge 11 is Not more than 30°, the design of this small angle can facilitate the pl...

Embodiment 2

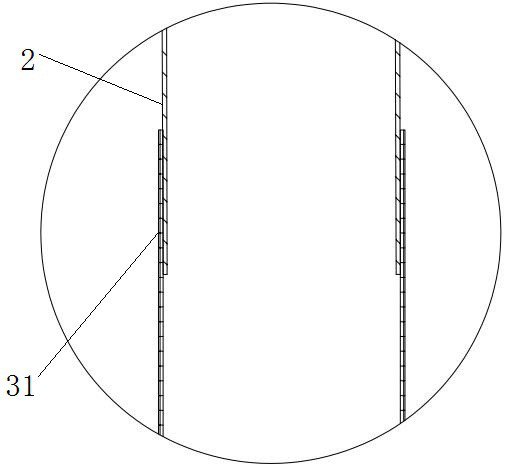

[0034] On the basis of Embodiment 1, the sleeve 31 adopts a buckle design, such as Figure 4 As shown, the sleeve 31 is a looped tube, and the inner wall of the contact part of the looped tube and the heat exchange section 2 is provided with several ring-shaped buckles 311 in the circumferential direction. At this time, the downward pressure of the indenter metal satisfies:

[0035]

[0036] Among them, G 2 : downward pressure of the indenter metal when the ring tube is used, b: height of the ring ring, d: tube outer diameter of the heat exchange section, n: number of ring rings, c: width of the ring ring .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com