Bloom performance test system and test method of tdi detector

A technology of highlight overflow and test system, which is used in TV, electrical components, image communication, etc., and can solve the problem of inability to obtain imaging parameter performance test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

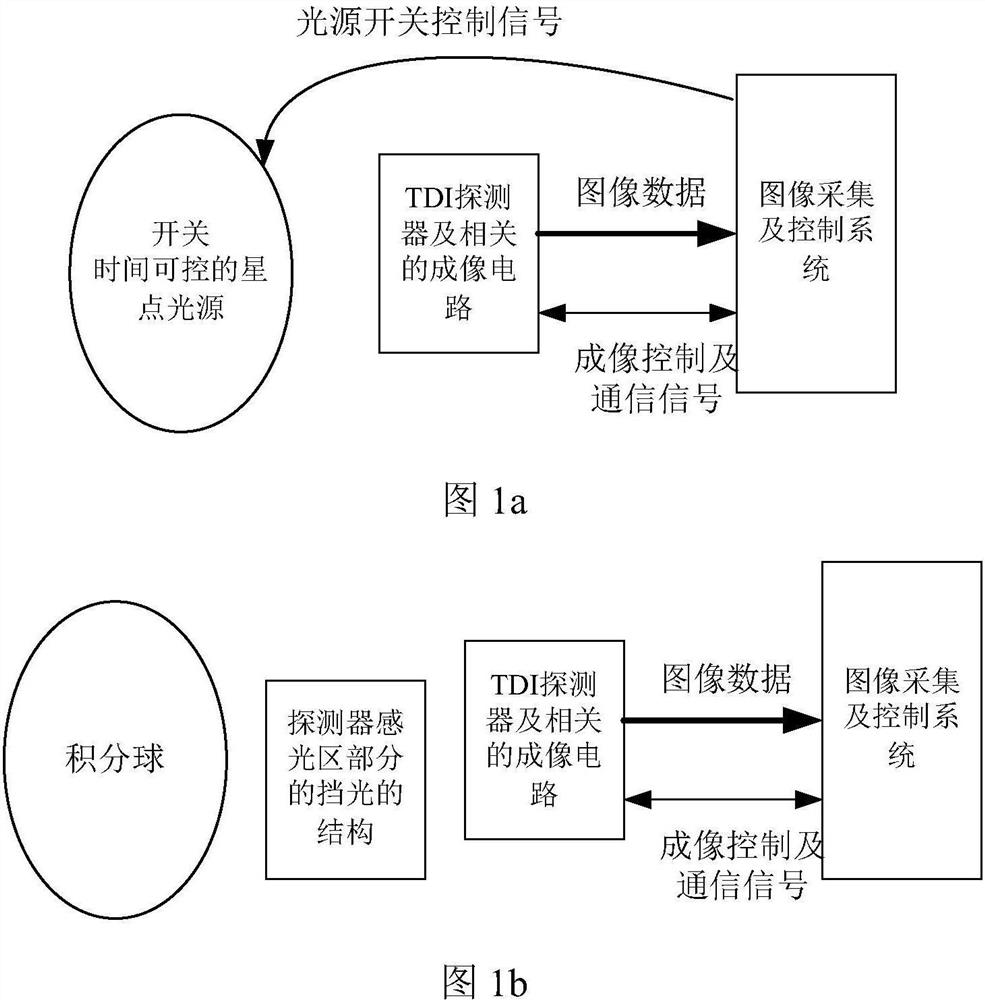

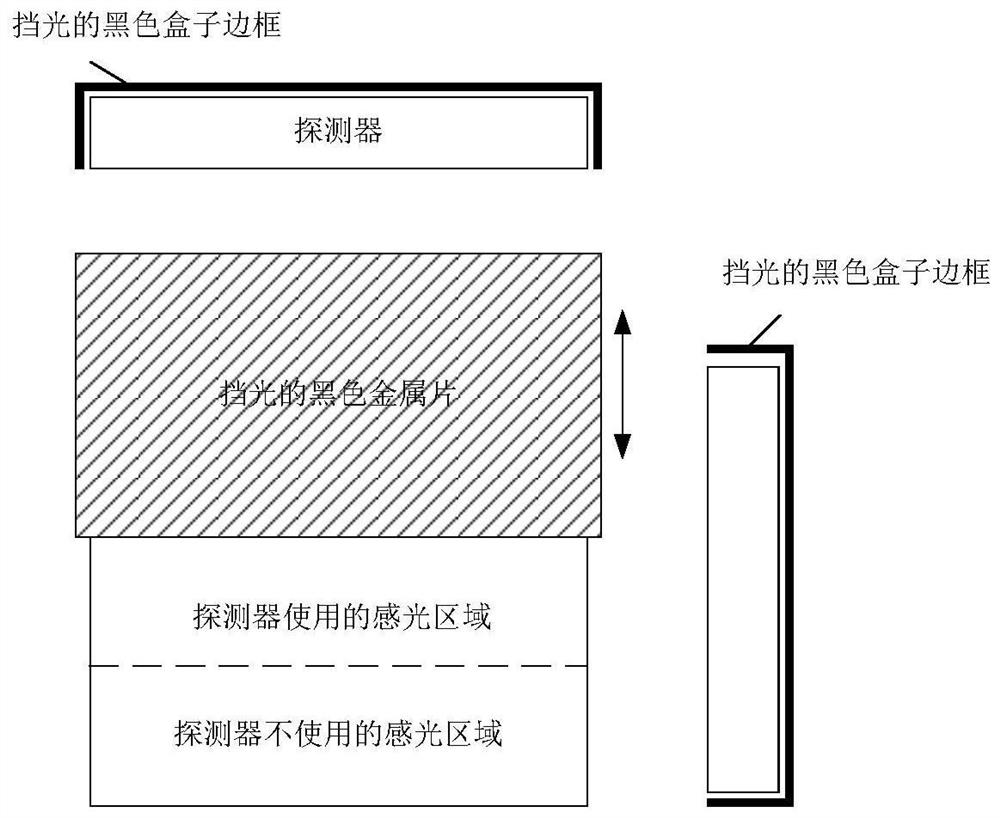

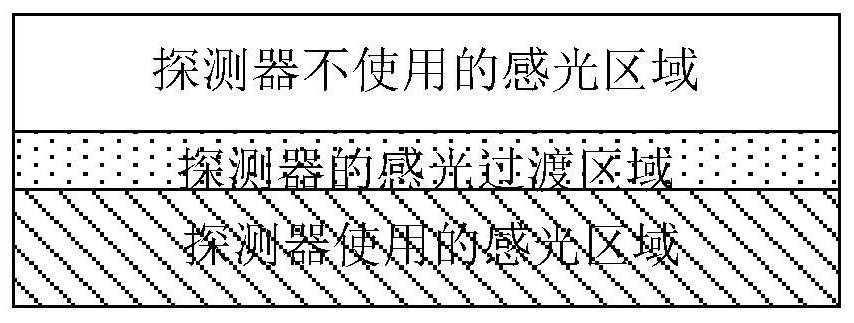

[0026] Specific implementation mode 1. Combination Figure 1 to Figure 3 Description of this embodiment, the TDI detector bloom performance test system mainly includes TDI detectors and related imaging circuits; light structure. It is mainly divided into CTE working mode test and TDI working mode with partial light blocking.

[0027] In the CTE area array mode, the star point light source with controllable switching time controlled by the image acquisition and control system is used as the illumination source of the TDI detector. The image acquisition and control system controls the TDI detector and related imaging circuits to generate Imaging control related signals, and communicate to obtain the imaging status; before the TDI detector starts to expose, turn on the star point light source with controllable switching time; when the TDI detector is exposed, turn off the star point light source with controllable switching time, and then Start the line-by-line transfer of charg...

specific Embodiment approach 2

[0029] Specific embodiment two, combine Figure 1 to Figure 3 Describe this embodiment, this embodiment is the test method of the TDI detector blown-out performance test system described in the first embodiment, the test method includes the blown-out performance detection under the CTE area array mode and the partial light-blocking TDI line array mode under Bloom performance detection.

[0030] The blooming performance detection process in the CTE area array mode is as follows:

[0031] A star point light source (small bright spot light source) with controllable switching time is used to form a small bright spot (a few pixels in size) after passing through the optical system, and the small bright spot is placed in the center of the photosensitive area; in the specified TDI series for level n (n max is the maximum available number of stages of the detector) to change the brightness of the star point, according to the saturated incident light energy I of the detector sat and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com