Green T-shirt fabric and preparation method

A green and fabric technology, applied in the processing of textile materials, knitting, spinning solution filtration, etc., can solve the problems of serious recycling pollution, difficulty in long-term shape retention, warm and airtight touch, etc., and achieve excellent diffusion and evaporation performance, Long-lasting comfort, good elasticity and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A green T-shirt fabric, the formula includes: Solona green renewable fiber and Solona special-shaped cross-section cool-feeling fiber; the mass percentages of each component are: 48-60% of Solona green renewable fiber and 40-52% Solona profiled cross-section cooling fibers.

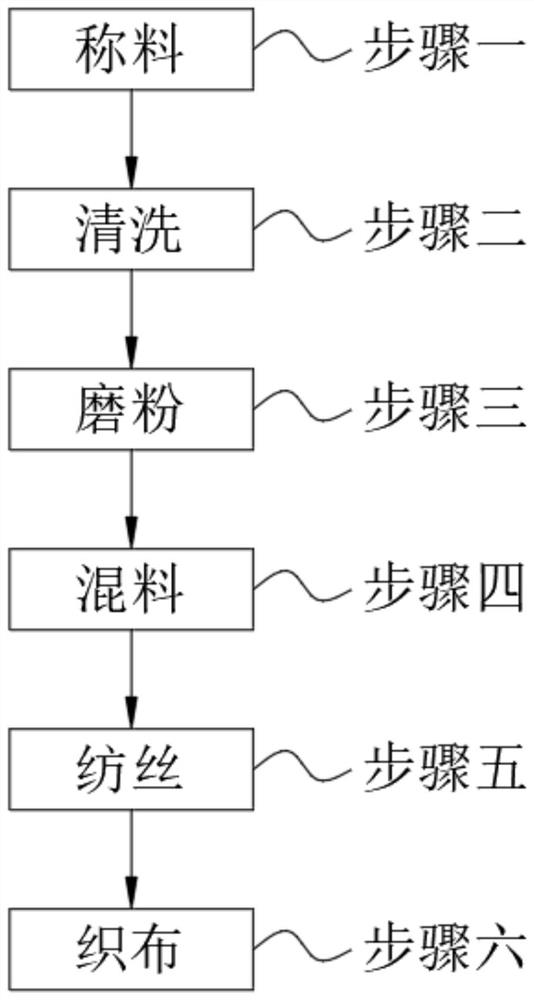

[0025] A method for preparing a green T-shirt fabric, comprising the following steps: Step 1, weighing; Step 2, washing; Step 3, grinding; Step 4, mixing; Step 5, spinning; Step 6, weaving;

[0026] Wherein in the above-mentioned step 1, according to the mass percentage of each component, weigh 48% of Solona green renewable fiber and 52% of Solona special-shaped cross-section cool-feeling fiber respectively, and set aside;

[0027] Among them, in the above-mentioned step 2, put the Solona green renewable fiber prepared in the step 1 and the Solona special-shaped cross-section cool-feeling fiber into the ultrasonic cleaning machine with a working frequency of 7-13kHz respectively, and add an appropr...

Embodiment 2

[0033] A green T-shirt fabric, the formula includes: Solona green renewable fiber and Solona special-shaped cross-section cool-feeling fiber; the mass percentages of each component are: 48-60% of Solona green renewable fiber and 40-52% Solona profiled cross-section cooling fibers.

[0034] A method for preparing a green T-shirt fabric, comprising the following steps: Step 1, weighing; Step 2, washing; Step 3, grinding; Step 4, mixing; Step 5, spinning; Step 6, weaving;

[0035] Wherein in the above step 1, according to the mass percentage of each component, weigh 54% of Solona green renewable fiber and 46% of Solona shaped cross-section cooling fiber respectively, and set aside;

[0036] Among them, in the above-mentioned step 2, put the Solona green renewable fiber prepared in the step 1 and the Solona special-shaped cross-section cool-feeling fiber into the ultrasonic cleaning machine with a working frequency of 7-13kHz respectively, and add an appropriate amount of 83:5:5:...

Embodiment 3

[0042] A green T-shirt fabric, the formula includes: Solona green renewable fiber and Solona special-shaped cross-section cool-feeling fiber; the mass percentages of each component are: 48-60% of Solona green renewable fiber and 40-52% Solona profiled cross-section cooling fibers.

[0043] A method for preparing a green T-shirt fabric, comprising the following steps: Step 1, weighing; Step 2, washing; Step 3, grinding; Step 4, mixing; Step 5, spinning; Step 6, weaving;

[0044] In the above step 1, according to the mass percentage of each component, weigh 60% of the Solona green renewable fiber and 40% of the Solona shaped cross-section cool-feeling fiber, and set aside;

[0045] Among them, in the above-mentioned step 2, put the Solona green renewable fiber prepared in the step 1 and the Solona special-shaped cross-section cool-feeling fiber into the ultrasonic cleaning machine with a working frequency of 7-13kHz respectively, and add an appropriate amount of 83:5:5:2:1 clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com