Czochralski single crystal thermal field and re-feeding process for thermal field

A single crystal, Czochralski technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., to achieve the effect of improving the quality of single crystal, reducing the broken rate of single edge, and improving the hit rate of resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

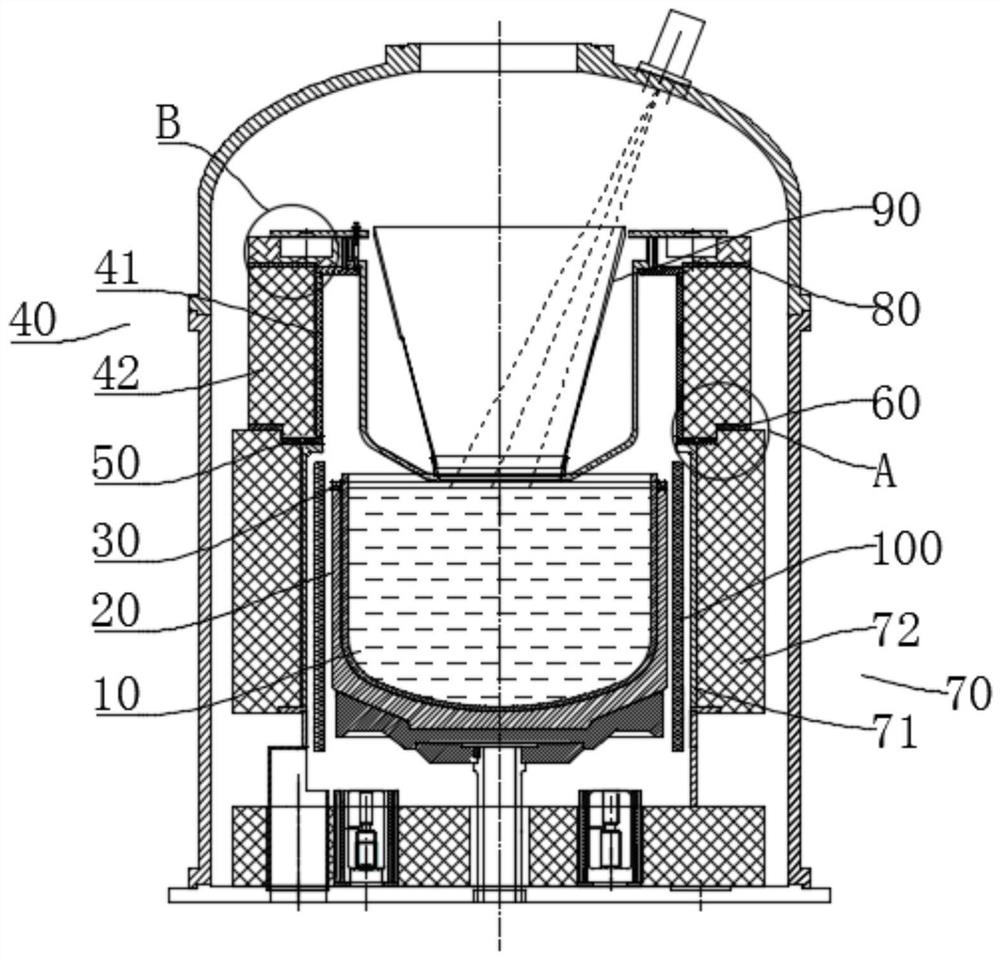

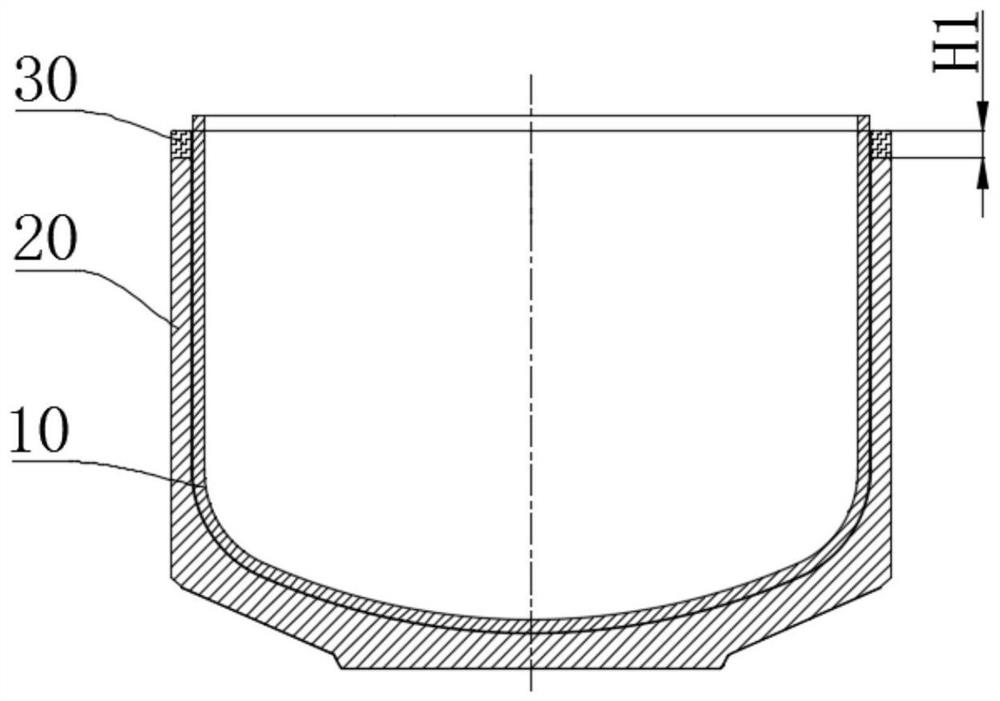

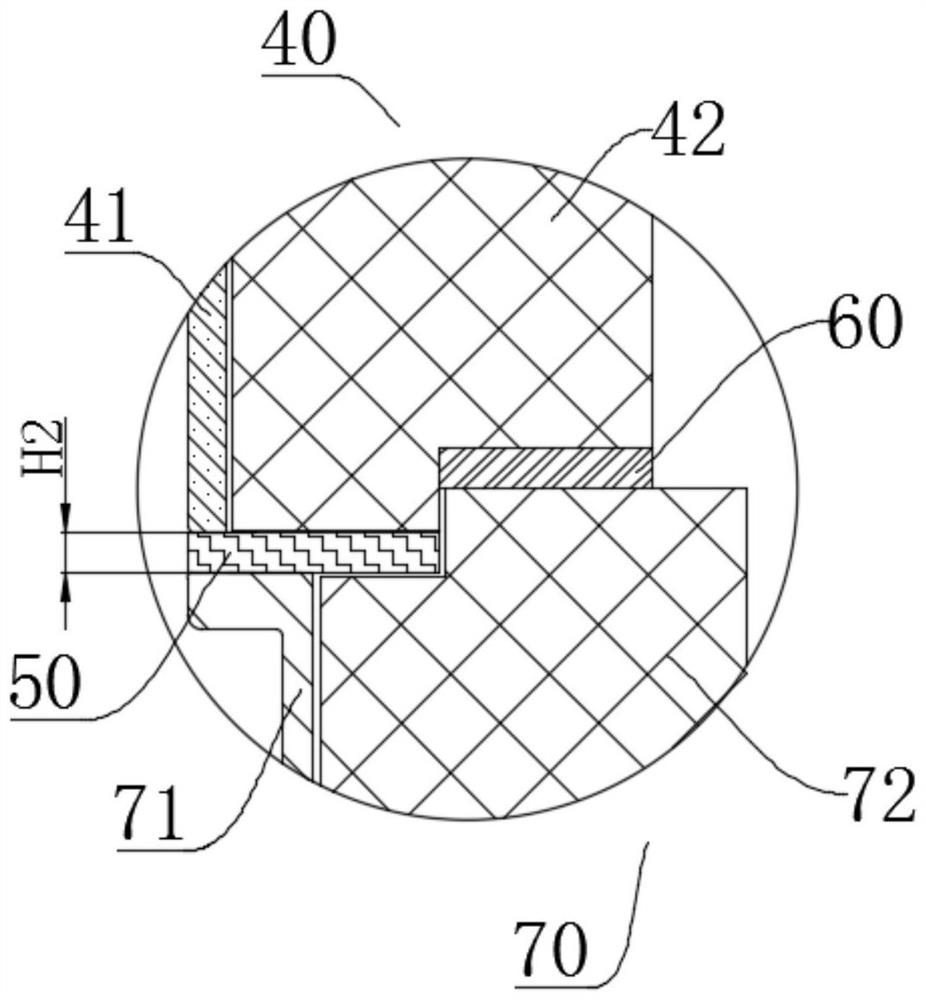

[0059] The diameter of the quartz crucible 10 is 28 inches. According to the limitation of the structural space of the thermal field of the single crystal furnace and the arrangement of the structure of the original graphite / carbon carbon crucible 20 and the heater 100, the height of the quartz crucible 10 is 20mm higher than that of the original conventional quartz crucible, and correspondingly, the supporting crucible 30 The height is 20mm, and the height of the first washer 60 and the second washer 80 are both 20mm. The distance from the lower end surface of the draft tube 60 to the molten silicon liquid level in the quartz crucible 10 is 20±2mm.

[0060] In this embodiment, the average seeding speed is 200-400mm / h, the increase of thermal field power is 1.5-4KW, and the variation of seeding power is shown in Table 1.

Embodiment 2

[0062] The diameter of the quartz crucible 10 is 30 inches. According to the limitation of the structural space of the thermal field of the single crystal furnace and the arrangement of the structure of the original graphite / carbon-carbon crucible 20 and the heater 100, the height of the quartz crucible 10 is 60mm higher than that of the original conventional quartz crucible. Correspondingly, the supporting crucible 30 The height is 60mm, and the heights of the first washer 60 and the second washer 80 are both 60mm. The distance from the lower end surface of the draft tube 60 to the molten silicon liquid level in the quartz crucible 10 is 20±2mm.

[0063] In this embodiment, the average seeding speed is 200-400mm / h, the increase of thermal field power is 1.2-3.5KW, and the variation of seeding power is shown in Table 1.

Embodiment 3

[0065] The diameter of the quartz crucible 10 is 32 inches. According to the limitation of the structural space of the thermal field of the single crystal furnace and the arrangement of the structure of the original graphite / carbon carbon crucible 20 and the heater 100, the height of the quartz crucible 10 is 80mm higher than that of the original conventional quartz crucible. Correspondingly, the supporting crucible 30 The height is 80mm, and the heights of the first washer 60 and the second washer 80 are both 80mm. The distance from the lower end surface of the draft tube 60 to the molten silicon liquid level in the quartz crucible 10 is 20±2mm.

[0066] In this embodiment, the average seeding speed is 200-400mm / h, the increase of thermal field power is 1-3KW, and the variation of seeding power is shown in Table 1.

[0067] From the above analysis, it can be seen that when the seeding speed is greater than 300mm / h, it can be judged that the stable temperature is low. At this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com