Alloy shell part anodizing equipment with high sealing performance

A sealing and anodizing technology, which is applied in the field of alloys, can solve the problems of reducing the sealing effect and damage of the PTFE tape, and achieve the effect of preventing and strengthening the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

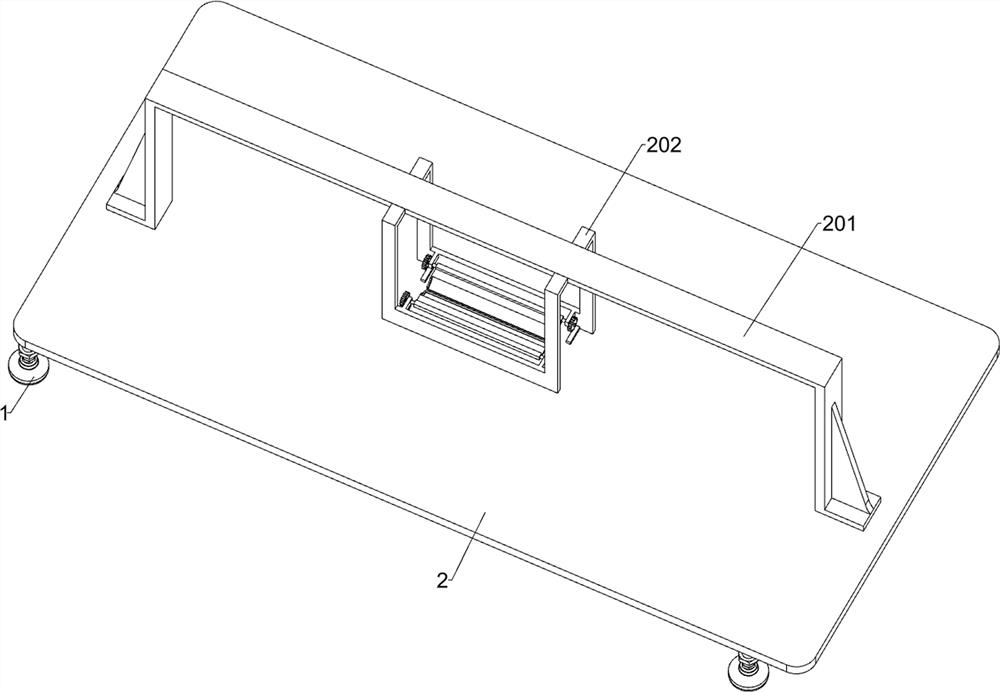

[0032]An anodizing equipment for alloy shell parts with strong sealing, such as Figure 1-9 As shown, it includes feet 1, a first mounting plate 2, a support unit and a sealed soaking unit; the top of the four feet 1 is connected to the first mounting plate 2; the upper middle of the first mounting plate 2 is connected to a support unit; The unit is connected with a sealed immersion unit.

[0033] The support unit includes a first mounting frame 201, a second mounting plate 202, a first transmission shaft 203, a convex plate 204, an arc plate 205 and a first spur gear 206; The mounting frame 201; the front side and the rear side of the first mounting frame 201 are fixedly connected with a second mounting plate 202 respectively; The lower parts of the opposite sides of the mounting plate 202 are respectively fixedly connected with two convex plates 204 arranged symmetrically, and the four convex plates 204 are located below the two first transmission shafts 203; the middle par...

Embodiment 2

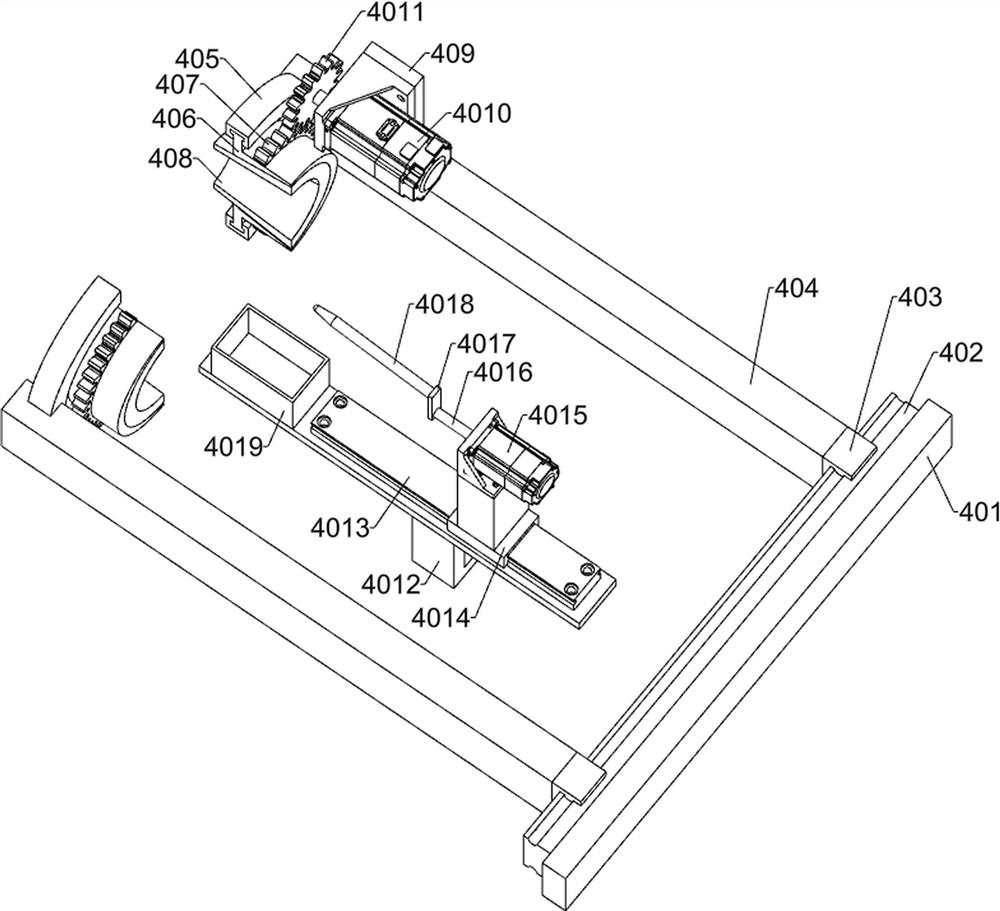

[0040] On the basis of Example 1, such as figure 1 with Figure 10-12 As shown, it also includes a seal cleaning unit; the first mounting plate 2 is connected with two seal cleaning units; the support unit is connected with two seal cleaning units, and the two seal cleaning units are symmetrically arranged left and right; The seal cleaning unit includes a fifth mounting plate 401, a fourth electric slide rail 402, a third electric slide block 403, a sixth mounting plate 404, an arc slide rail 405, an arc slide block 406, an arc gear 407, Arc sponge plate 408, the seventh mounting plate 409, the second motor 4010, the fifth spur gear 4011, the fifth mounting frame 4012, the second electric slide rail 4013, the fourth electric slider 4014, the third motor 4015, the second Transmission shaft 4016, connecting rod 4017, extrusion rod 4018 and second collection box 4019; the right side of the first mounting frame 201 is fixedly connected with the fifth mounting plate 401; the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com