Liquid injection sintering equipment based on high-purity strontium titanate powder material and use method

A technology of strontium titanate powder and sintering equipment, which is applied in the field of liquid injection sintering equipment based on high-purity strontium titanate powder materials, can solve the problems of reducing the purity of SrTiO3 materials, high energy consumption, high temperature, etc., and achieves reduction in sintering. Energy consumption, large contact area, and effect of reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

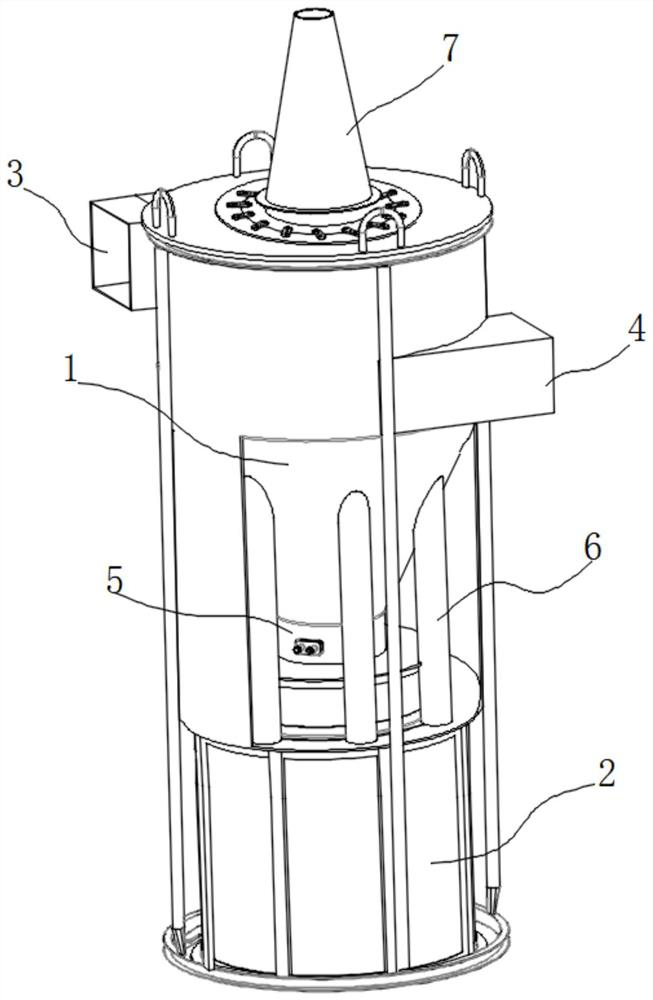

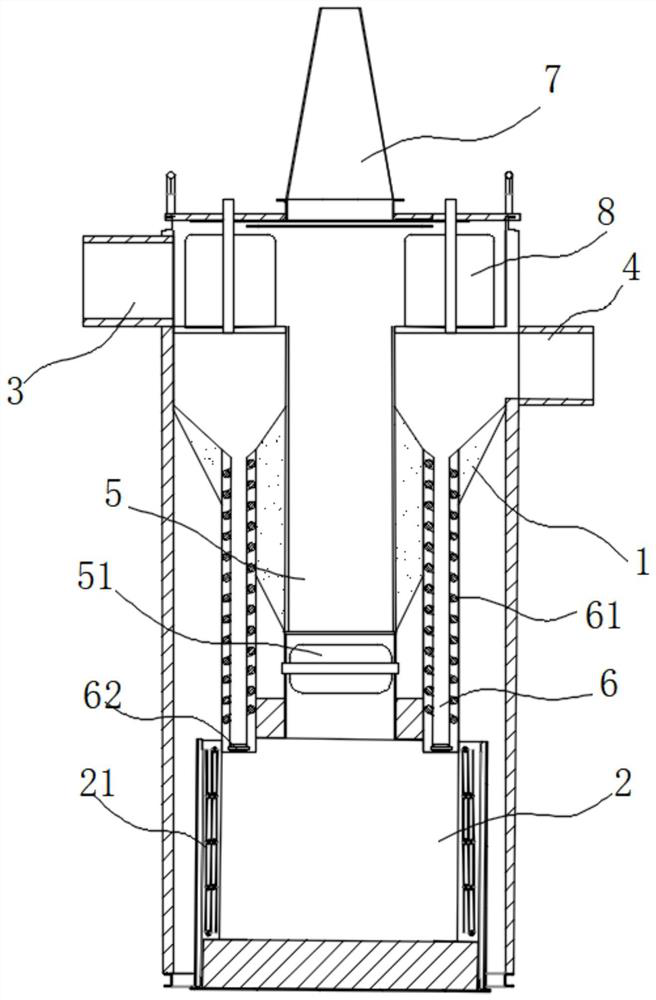

[0035] see figure 1 and 2 , in an embodiment of the present invention, a liquid injection sintering equipment based on high-purity strontium titanate powder material, comprising:

[0036] In the separation chamber 1, the side walls are respectively provided with feed inlet 1 3 and feed inlet 2 4 staggered up and down;

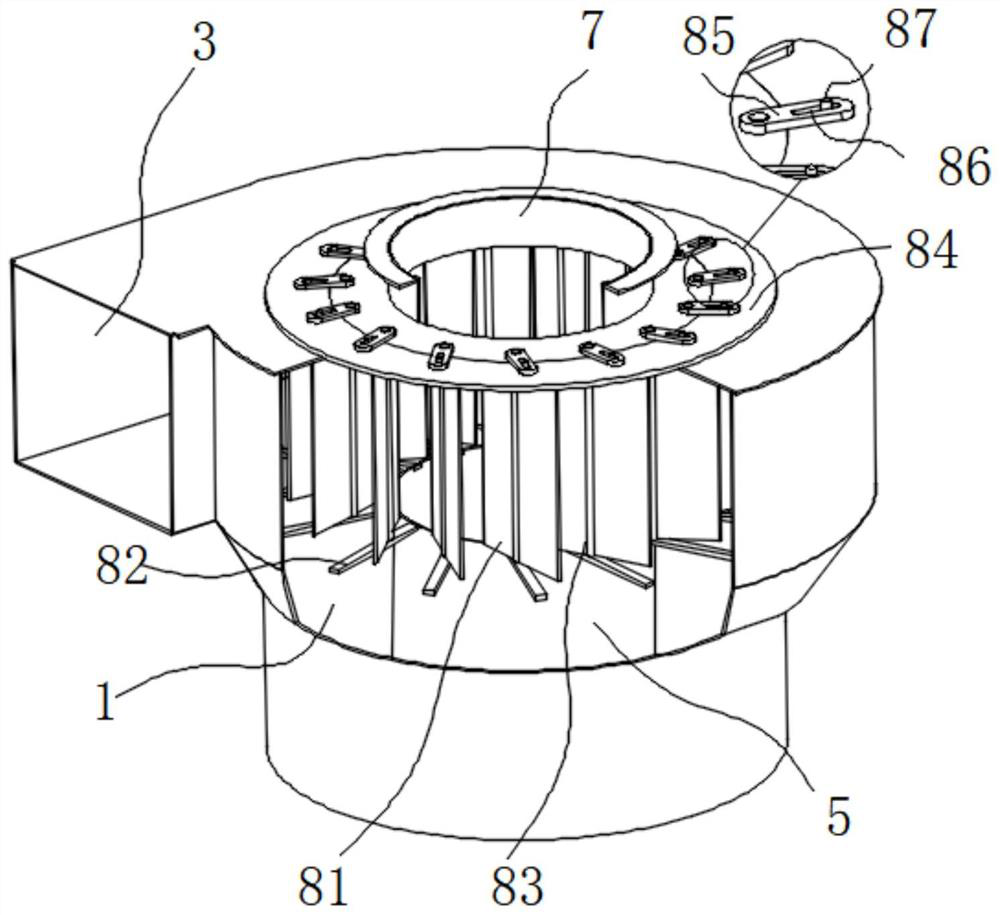

[0037] The screening and separation assembly 8 is arranged in the separation chamber 1 at a position corresponding to the plane where the feed inlet-3 is located;

[0038] The mixing chamber 2 is fixed below the separation chamber 1, and the center above the mixing chamber 2 is connected with a central pipe 5 connected above the center of the separation chamber 1, and a discharge door is also opened in the mixing chamber 2;

[0039] There are a plurality of liquid injection pipes 6 distributed along the outer circumference of the central pipe 5 , and they pass through the separation chamber 1 and the mixing chamber 2 .

[0040] see image 3 , in this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com