Lightweight tile adhesive and preparation method thereof

A tile adhesive and light-weight technology, applied in the field of tile adhesive, can solve the problems of uneven separation and use, and achieve the effects of improving the performance after immersion in water, improving the strength of drying, and improving the bonding strength of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

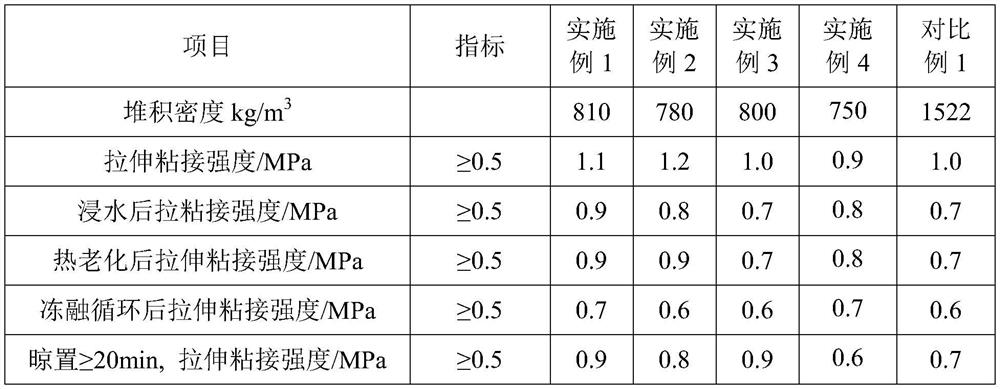

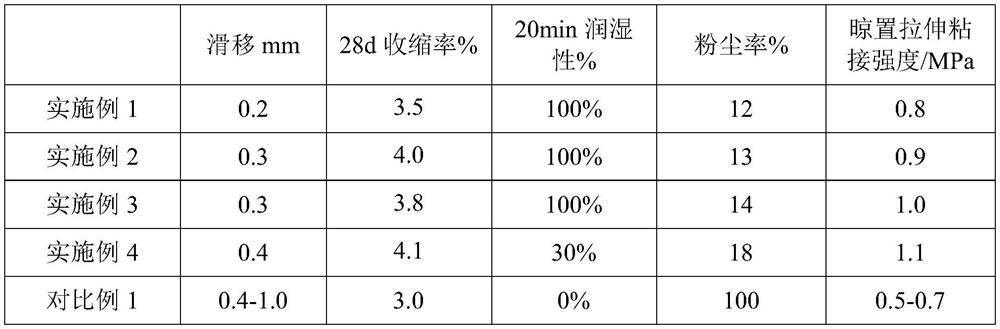

Examples

Embodiment 1

[0062] This embodiment provides a lightweight tile adhesive and a preparation method thereof.

[0063] The preparation method includes:

[0064] (1) Obtain coated light sand

[0065] 100 parts by weight of particle size gradation is 40-140 mesh, bulk density is 750kg / m 3 The ceramsite sand prepared by fly ash through granulation and sintering-free process is immersed in 100 parts by weight of silicone oil, and stirred evenly at 450rpm for 50min. After all the light sand aggregates are gathered at the bottom of the mixing tank, pour out the upper liquid. Then mix and disperse with 40 parts by weight of 400 mesh heavy calcium powder to obtain coated light sand with a particle size of 40-140 mesh. Wherein, the wetting liquid covers 100% of the area of the lightweight sand aggregate, and the superfine powder covers 100% of the area of the wetted lightweight sand aggregate.

[0066] (2) Obtain light tile adhesive

[0067] 180 parts by weight of coated light sand obtained in...

Embodiment 2

[0069] This embodiment provides a lightweight tile adhesive and a preparation method thereof.

[0070] The preparation method includes:

[0071] (1) Obtain coated light sand

[0072] 100 parts by weight of particle size gradation is 40-140 mesh, bulk density is 600kg / m 3 Immerse the power plant slag sand in 100 parts by weight of silicone oil, and stir evenly at 300rpm for 45 minutes. After all the lightweight sand aggregates are gathered at the bottom of the mixing tank, pour out the upper liquid, and then mix and disperse with 40 parts by weight of 400 mesh heavy calcium powder. , to obtain coated light sand with a particle size of 40-140 mesh. Wherein, the wetting liquid covers 100% of the area of the lightweight sand aggregate, and the superfine powder covers 100% of the area of the wetted lightweight sand aggregate.

[0073] (2) Obtain light tile adhesive

[0074] 180 parts by weight of coated light sand obtained in step (1), 260 parts by weight of ordinary Portla...

Embodiment 3

[0076] This embodiment provides a lightweight tile adhesive and a preparation method thereof.

[0077] The preparation method includes:

[0078] (1) Obtain coated light sand

[0079] 100 parts by weight of particle size gradation is 40-140 mesh, bulk density is 700kg / m 3 The power plant slag sand is immersed in 100 parts by weight of silicone oil, and stirred evenly at 350rpm for 40 minutes. After all the light sand aggregates are gathered at the bottom of the mixing tank, the upper liquid is poured out, and then mixed with 50 parts by weight of 400 mesh semi-encrypted silica fume. Disperse to obtain coated light sand with a particle size of 40-140 mesh. Wherein, the wetting liquid covers 100% of the area of the lightweight sand aggregate, and the superfine powder covers 100% of the area of the wetted lightweight sand aggregate.

[0080] (2) Obtain light tile adhesive

[0081] 180 parts by weight of coated light sand obtained in step (1), 260 parts by weight of ordinar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com