A heat-loading machine for embedded aluminum rollers that can quickly cool down

An embedded and fast technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of the top of the aluminum rollers offset, unable to install quickly, water splashing to other places, etc., to achieve easy access, improve The effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

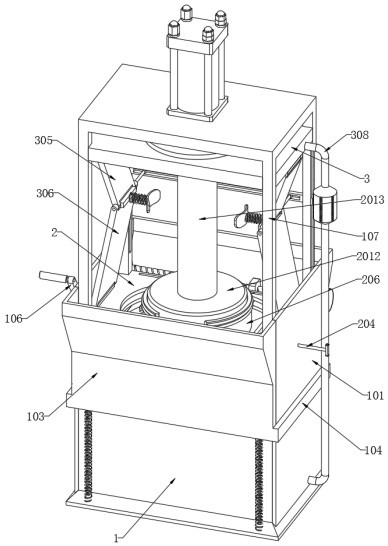

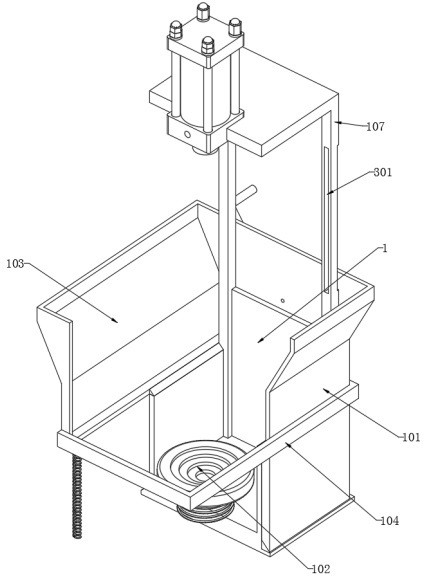

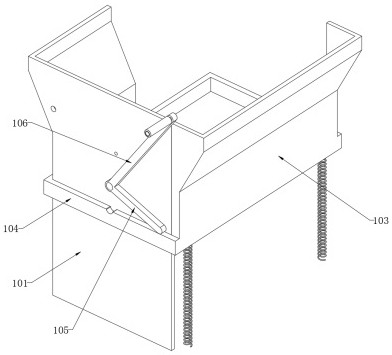

[0038] Example: please refer to Figure 1 to Figure 9 :

[0039] The present invention proposes a heat-mounting machine for embedded aluminum rollers that can rapidly cool down, including: a main body 1, a base is installed at the bottom of the main body 1, and a connecting plate 107 is installed in the four corner grooves on the top of the main body 1, and the connecting plate 107 A hydraulic cylinder is installed on the top, and a carrier plate 2 is installed on the top of the main body 1; the carrier plate 2 has a rectangular structure, and a storage tank 208 is opened on the top of the carrier plate 2, and the four corners of the carrier plate 2 are clamped with the connecting plate 107; the connecting plate 107 The bottom end of the top hydraulic cylinder is installed with a pressure plate 3; the bottom of the pressure plate 3 is provided with a groove, and the bottom of the pressure plate 3 is installed with a water spray 307, and one side of the pressure plate 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com