Fuel cell metal polar plate lubricating and stamping method and polar plate workpiece

A metal plate and fuel cell technology, applied in the field of stamping, can solve the problems of reducing stress concentration, insufficient deformation of the plate, poor bonding between the mold and the plate, etc., to improve forming accuracy, promote relative sliding, and reduce stress concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

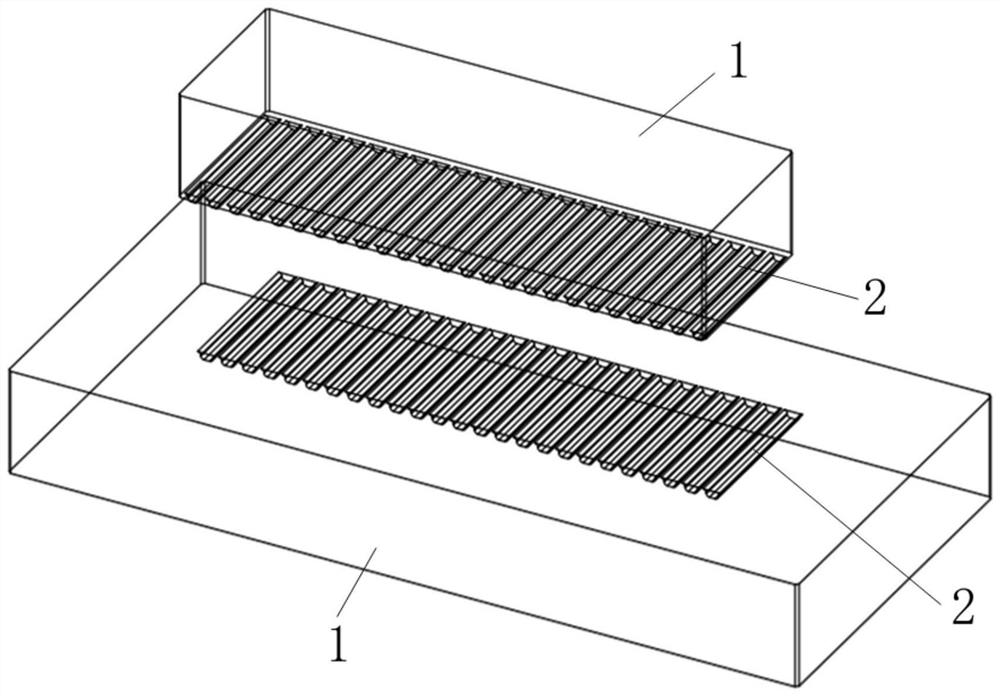

[0035] In a typical embodiment of the present invention, such as Figure 1-Figure 7 As shown, a fuel cell metal plate lubricating stamping method is given.

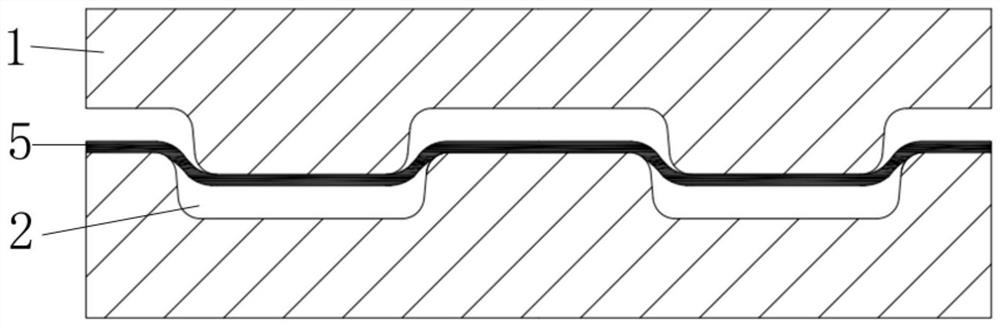

[0036] Such as Figure 2-Figure 5 The fuel cell metal plate lubricated stamping method shown is to stamp the structure of the fuel cell plate, and set the compound lubrication method to improve the precision in the stamping process, meet the needs of the plate for the characteristic structure, and achieve uniform thickness distribution and good forming effect. Good purpose, can get such as Figure 7 The plate workpiece 6 shown.

[0037] Under the traditional lubrication method, the lubricant 4 is directly added between the mold 1 and the plate 5 for lubrication. The flow of the lubricant 4 will cause the lubrication effect to deteriorate, resulting in insufficient stamping precision, such as Image 6 A conventional plate workpiece 7 is shown.

[0038] The fuel cell metal plate lubricating stamping method in this embod...

Embodiment 2

[0056] In another typical embodiment of the present invention, such as Figure 1-Figure 7 As shown, a polar plate workpiece is given.

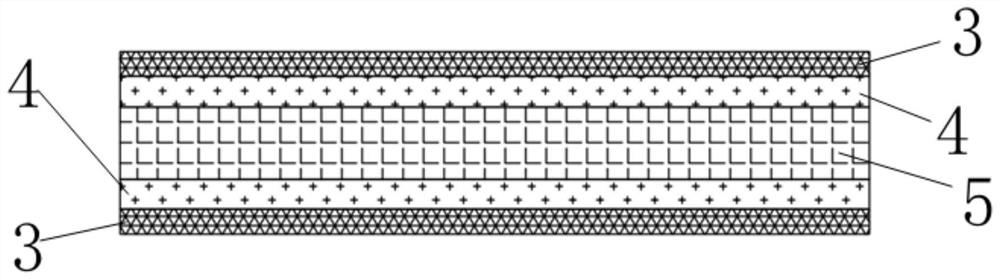

[0057] Adopt the fuel cell metal pole plate lubricating stamping method as in embodiment 1 to carry out stamping process to plate 5, as Figure 1-Figure 5 As shown, the surface of the plate 5 is coated with a lubricant 4 and covered with a film 3. After stamping, it is deformed together with the plate 5 under the action of the mold 1, so that the plate 5 forms a characteristic structure, and the following is obtained: Figure 7 Plate workpiece 6 shown.

[0058] The film 3, which has a tensile strength and elongation greater than that of the plate 5 to be processed, is used as an auxiliary lubricating structure. After being covered with the lubricant 4, it cooperates with the solid lubrication of the lubricant 4 and the film 3 body to promote the contact between the plate 5 and the mold during the stamping process. The relative sliding of 1 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com