Method for actuating a dosing valve

A technology for metering valves and driving nozzles, which is applied in the direction of reactant parameter control, electrochemical generators, machines/engines, etc. It can solve problems such as nozzle freezing, fuel cells that cannot be restarted, and hydrogen dosing that can no longer be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following description of embodiments of the invention, identical or similar elements are identified with the same reference numerals, wherein in individual cases a repeated description of these elements is omitted. The figures show only schematically the subject-matter of the invention.

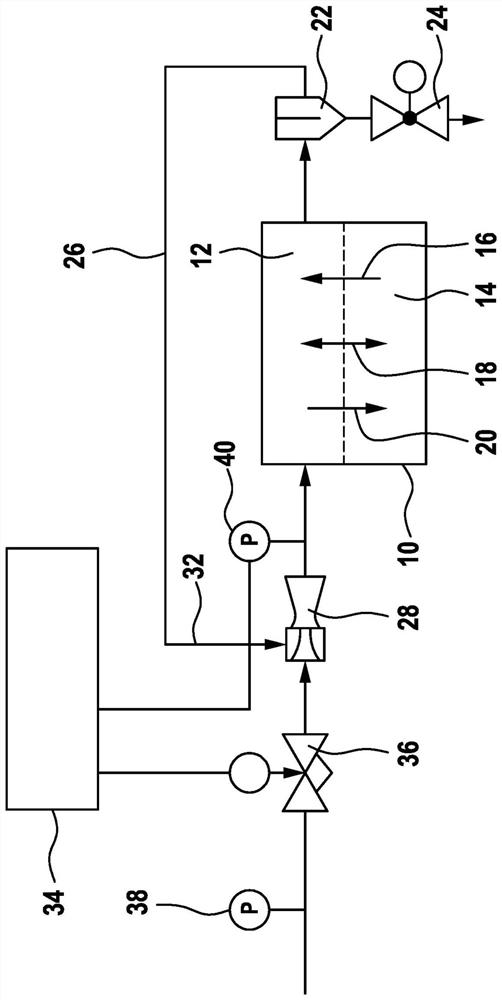

[0028] figure 1 A diagram showing components of a fuel cell system with a dosing valve, an injection pump, a fuel cell, and a controller.

[0029] by figure 1 The diagram shown in FIG. 1 shows that a fuel cell system 10 , one of which is illustrated here as an example of a fuel cell, includes an anode-side path 12 and a cathode-side path 14 . Within the fuel cell system 10, N from the ambient air from the cathode side path 14 to the anode side path 12 occurs. 2 Diffusion16. Water exchange 18 occurs between the anode-side path 12 and the cathode-side path 14, and in addition H from the anode-side path 12 into the cathode-side path 14 2 Diffusion 20.

[0030] On the outlet s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com