SRM torque distribution function control system and method based on interval segmentation

A technology of torque distribution function and control system, which is applied in the direction of control system, vector control system, control generator, etc., and can solve the problem that the torque ripple suppression effect needs to be improved, the torque ripple is not enough to compensate the torque drop of the previous phase And other problems, to achieve the effect of shortening the demagnetization time, reducing switching loss and speeding up the demagnetization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

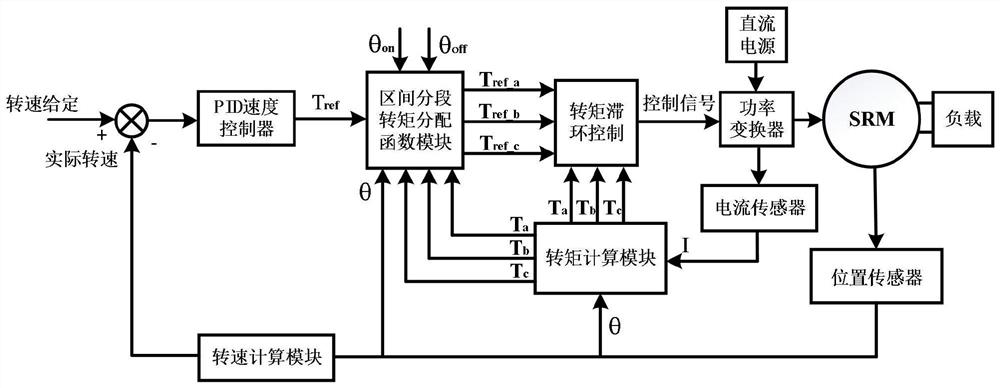

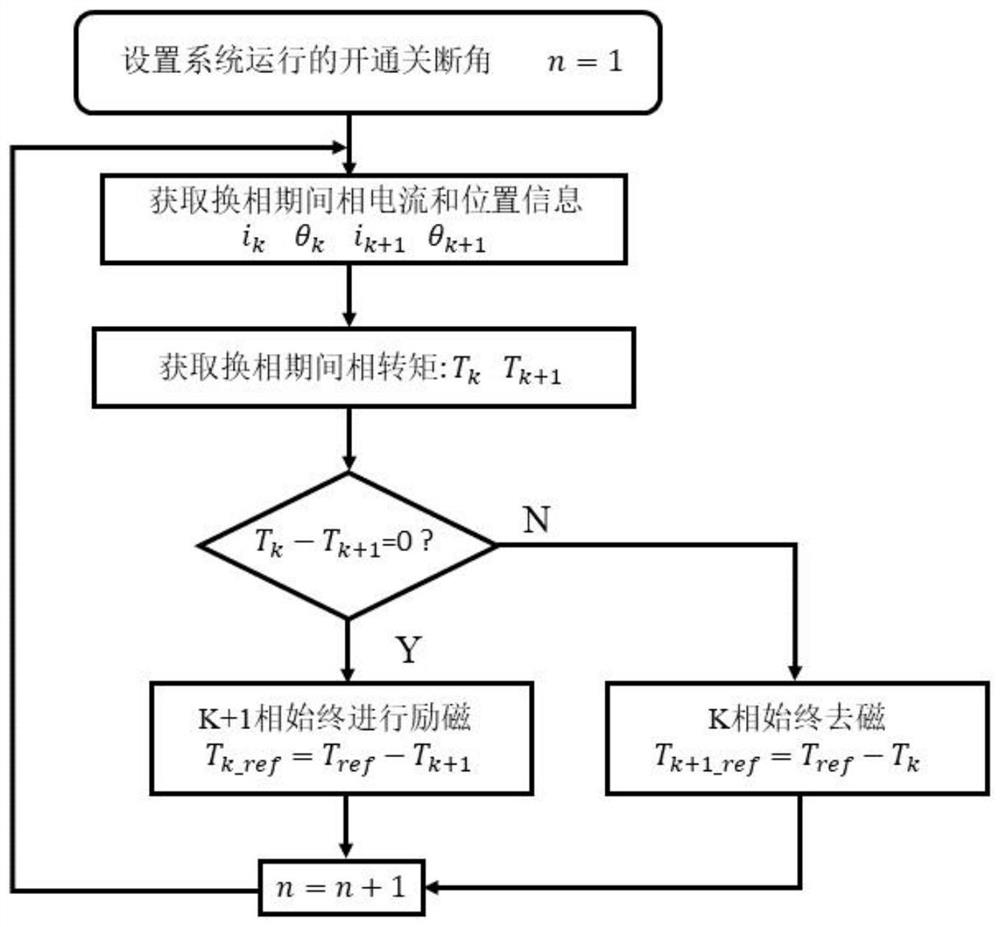

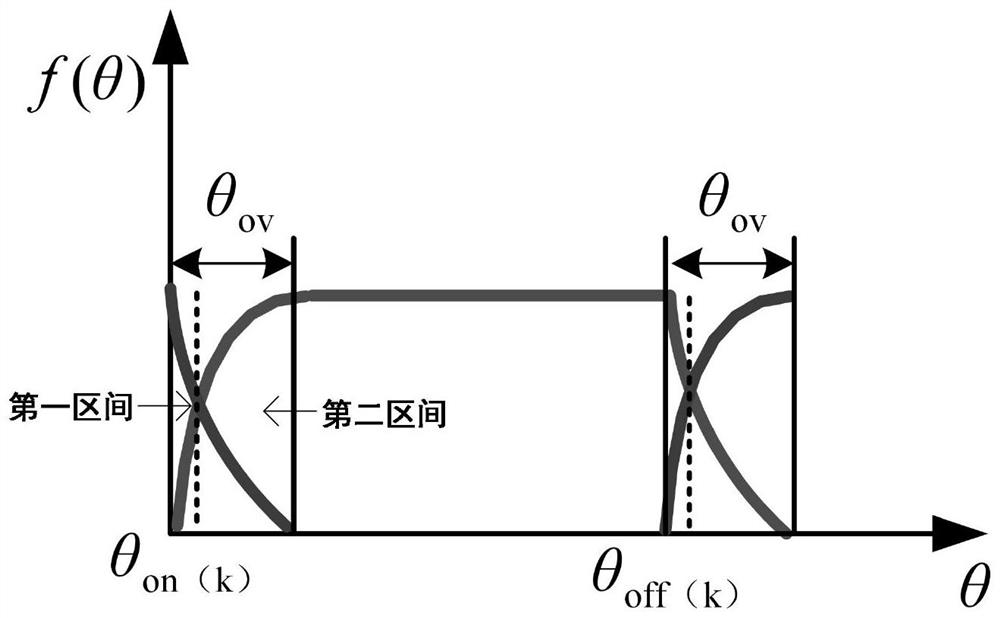

[0049] The purpose of this embodiment is to provide a switching reluctance motor torque distribution function control system based on interval segmentation, the system includes: a switched reluctance motor, a position sensor, a power converter, a current sensor, a controller, and the controller includes PID speed controller, torque hysteresis controller, speed calculation module, torque calculation module and interval segment torque distribution function module:

[0050] Obtain the feedback position signal of each phase according to the position sensor, obtain the feedback current value of each phase according to the current sensor, and the controller generates a driving signal according to the feedback position signal of each phase and the feedback current value of each phase to control the opening of the switching device of the power converter and off; the position sensor is connected to the switched reluctance motor body and also to the controller, and the current sensor is ...

Embodiment 2

[0096] The purpose of this embodiment is to provide a switched reluctance motor.

[0097] A switched reluctance motor, comprising the above-mentioned zone-based switched reluctance motor torque distribution function control system, and executing the above-mentioned zone-based switched reluctance motor torque distribution function control method.

[0098] The above embodiments provide a system and method for controlling the torque distribution function of switched reluctance motors based on intervals and segments, which has no requirement on the number of motor phases, has good universality, and has good application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com