Doubly-fed induction generator low-voltage ride-through control system

A doubly-fed induction motor, low voltage ride through technology, applied in motor generator control, control system, vector control system, etc., can solve problems such as poor control characteristics and long demagnetization process of stator flux linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings.

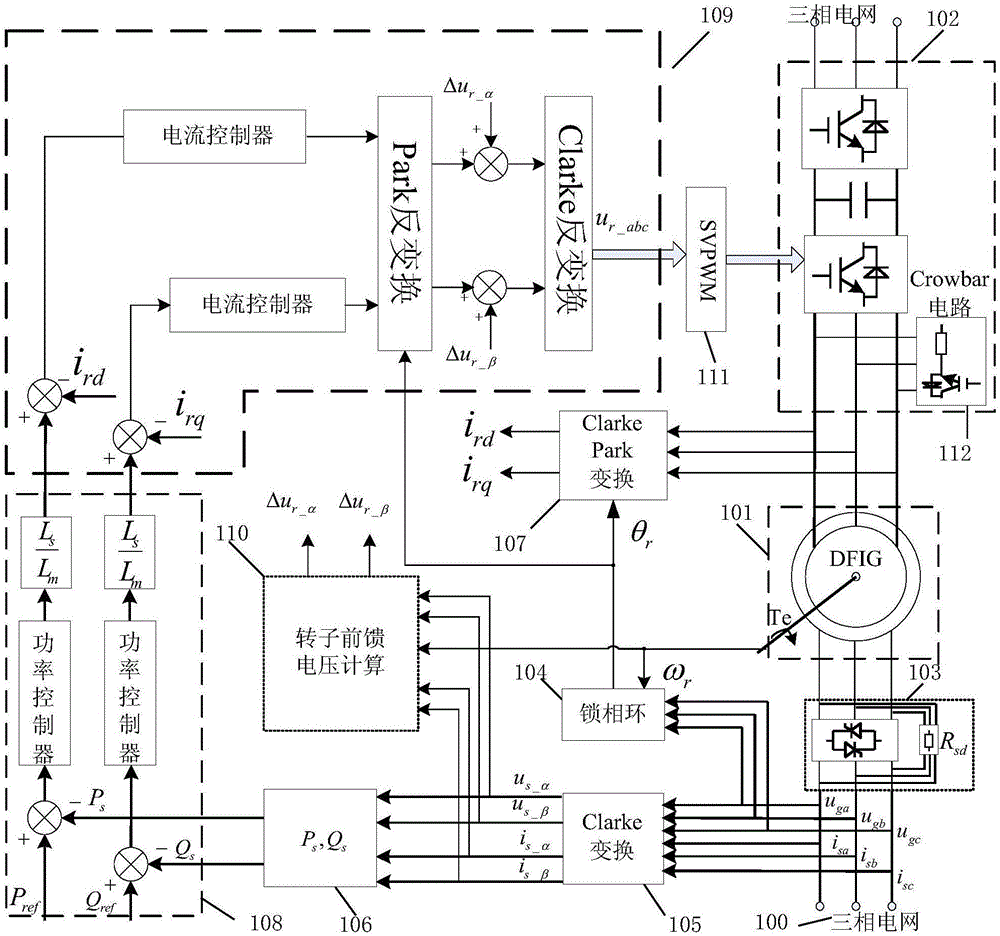

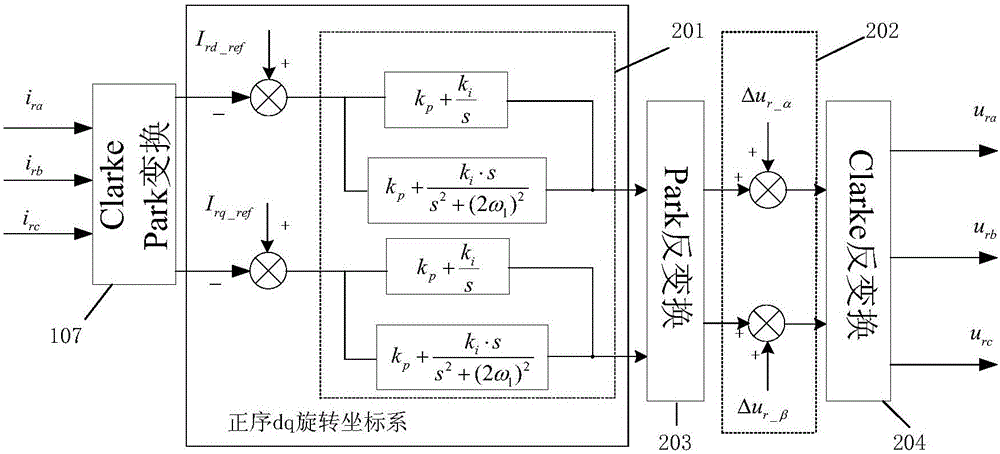

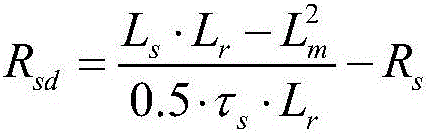

[0042] refer to figure 1 and figure 2 , a doubly-fed induction motor low-voltage ride-through control system, including a three-phase grid 100, a doubly-fed motor 101, a converter 102, a stator damping resistance switching device 103, a phase-locked loop 104, a stator voltage-current clarke conversion unit 105, Stator active power / reactive power calculation unit 106, rotor current clarke / park conversion unit 107, power outer loop 108, rotor current inner loop 109, rotor feedforward voltage calculation unit 110, SVPWM modulation calculation unit 111 and Crowbar circuit 112.

[0043] The three-phase grid 100 is a three-phase AC power supply after the 35KV bus of the grid passes through a 35KV / 690V transformer. The rotor winding of the double-fed induction generator 101 is connected to the rotor converter of the converter 102, the stator winding is connected to the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com