Preparation method and application of square laminated lithium ion battery capable of improving stress

A lithium-ion battery and lamination technology, which is applied in the manufacture of electrolyte batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of battery cycle performance attenuation, uneven force on electrode groups, side reactions, etc., and achieve great practical significance and improve Cycling performance, stress concentration relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

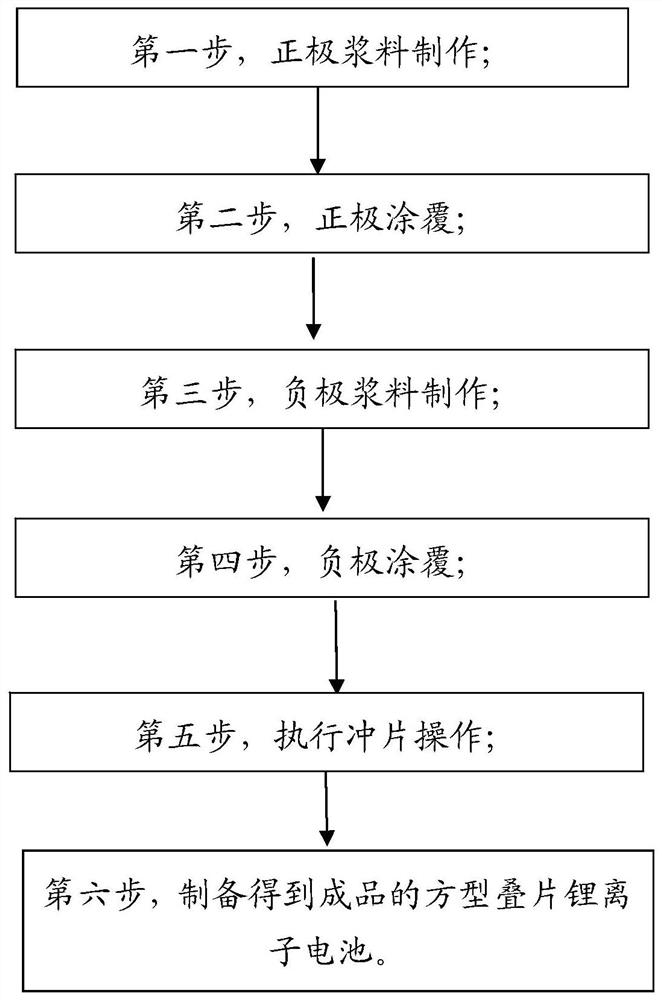

[0024] see Figure 1 to Figure 3 , the invention provides a method for preparing a square laminated lithium-ion battery capable of improving stress, comprising the following steps:

[0025] The first step is to make the positive electrode slurry: mix the positive electrode active material (such as the positive electrode lithium iron phosphate material), the conductive agent and the binder according to the mass ratio of 96:2:2, then put them into the solvent and stir them evenly, and mix them Obtain positive electrode slurry;

[0026] In the first step, the solute of the positive electrode slurry includes a positive electrode active material, a conductive agent and a binder. The solvent is N-methylpyrrolidone or water;

[0027] The solid content of the positive electrode slurry is 50-65%.

[0028] In the first step, the positive electrode active material, including but not limited to any one of lithium iron phosphate, nickel-cobalt-manganese ternary, nickel-cobalt-aluminum t...

Embodiment 1

[0107] Based on the first coating method of the positive electrode sheet provided by the present invention, a finished laminated battery is prepared. Specifically include the following steps:

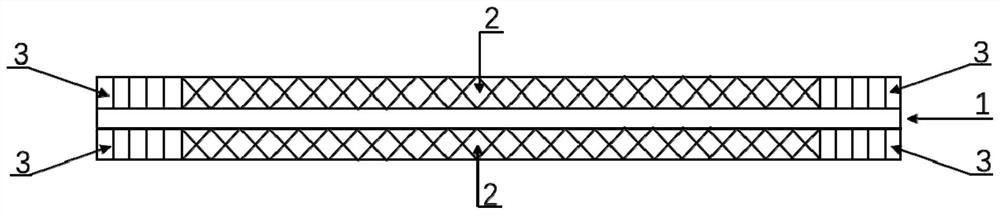

[0108] 1. Coat the positive electrode slurry and ceramic glue uniformly on the positive electrode current collector at the same time, and obtain the positive electrode sheet after drying and rolling. The positive plate is provided with an upper ceramic glue area, a slurry area and a lower ceramic glue area. The positive electrode slurry area is adjacent to the upper and lower ceramic areas. In order to ensure the N / P ratio, the coating amount of the positive electrode slurry area is uniform in the width of the positive electrode slurry area, and the coating amount is set to 40mg / cm 2 . The ceramic glue area is adjacent to the positive electrode slurry area, the upper and lower ceramic glue areas have a width of 6mm, and the ceramic glue area overlaps with the positive electrode slurry...

Embodiment 2

[0115] Based on the second coating method of the positive electrode sheet provided by the present invention, a finished laminated battery is prepared. Specifically include the following steps:

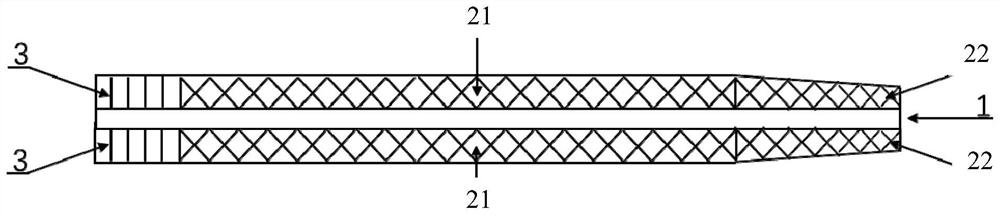

[0116] 1. Coat the positive electrode slurry on the current collector, and obtain the positive electrode sheet after drying in an oven and rolling. The positive electrode sheet is provided with a ceramic glue area, a positive electrode slurry normal coating area and a positive electrode slurry thinned coating area. The setting of the coating amount of the positive electrode sheet needs to ensure an appropriate N / P ratio to avoid lithium deposition in the battery. The positive electrode slurry normal coating area is adjacent to the ceramic glue area and the positive electrode slurry thinning coating area, wherein the coating amount from the positive electrode slurry normal coating area to the slurry thinning coating area gradually decreases, and the positive electrode slurry thinning c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com