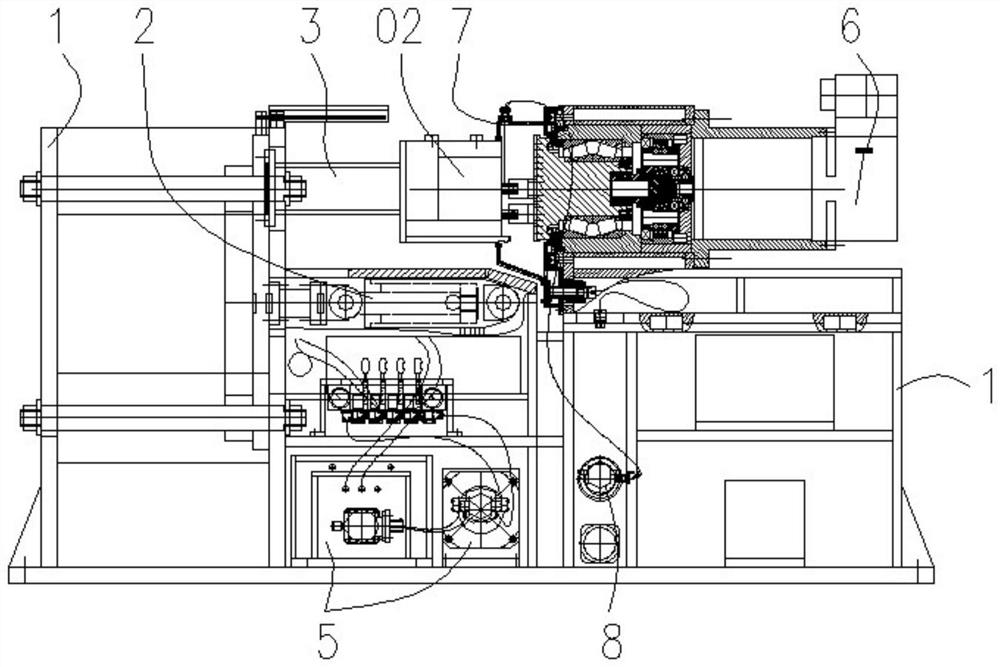

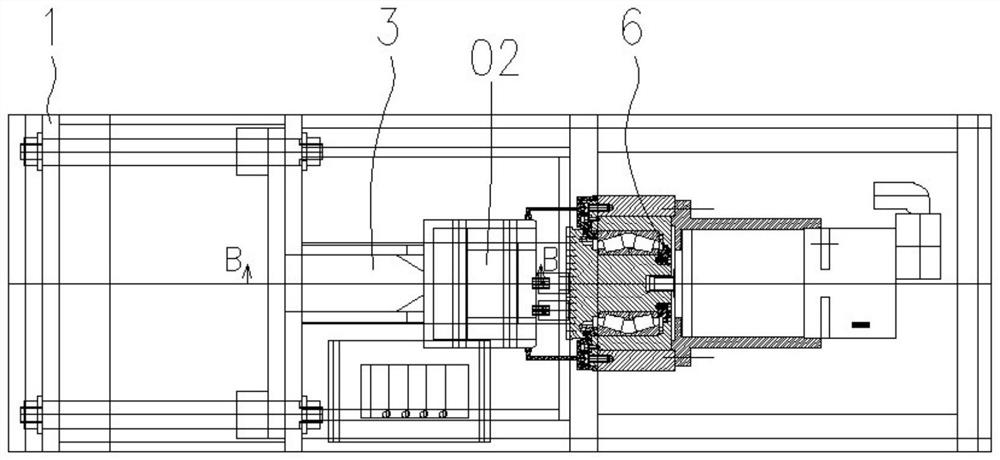

Spraying system and abrasion test bench

A technology of spraying system and abrasion test, which is applied in the field of spraying system, can solve the problems of wear failure, no spray cooling simulation, etc., and achieve the effect of reducing wear loss, ensuring cutting ability, and lengthening the abrasive path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

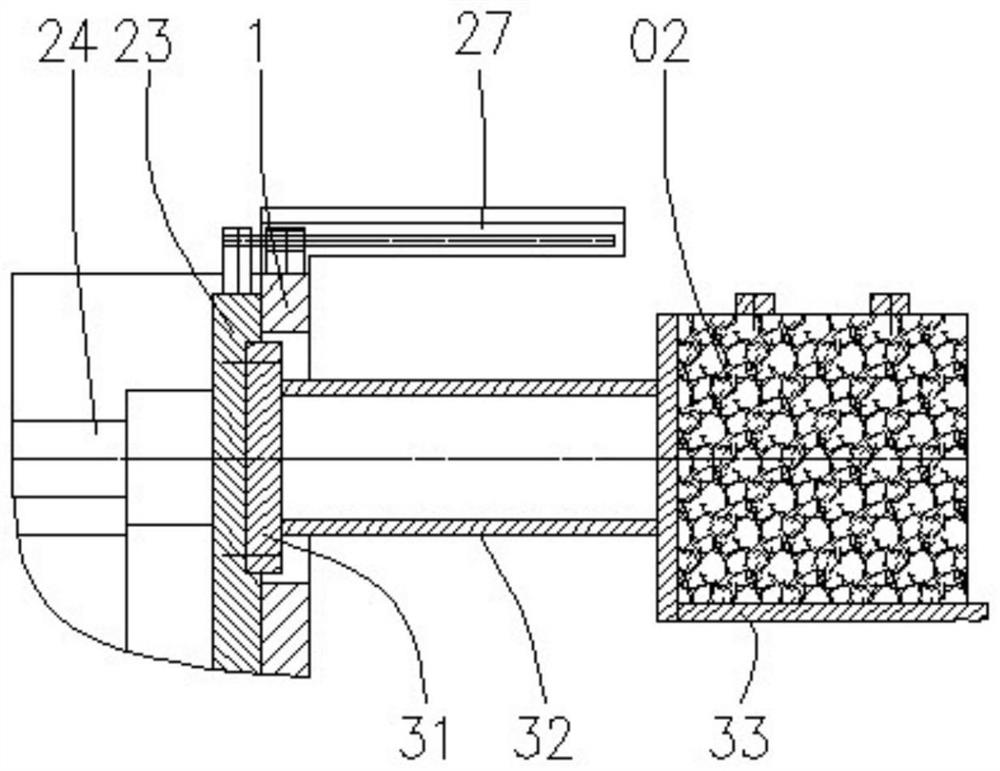

[0032] such as Figure 4-8 As shown, the present invention discloses a spray system, which includes a spray guard 7 and a water tank 17. The spray guard has a cylindrical structure that runs through from front to back. A front sealing groove 712 is arranged at the radially inner edge of the front end opening of the spray guard, and a front sealing structure 73 is arranged in the front sealing groove to form a seal with the abrasive rock sample holder 33 and the abrasive rock sample 02 in the abrasive rock sample holder during the abrasive test. The opening of the rear end of the spray protective cover is provided with an annular inner stop structure, the annular end face of the annular inner stop is provided with a rear sealing groove, and a rear sealing structure 72 is arranged in the rear sealing groove. A water inlet 75 and a water outlet 76 are respectively arranged at the top and bottom of the spray shield, and the water inlet is close to the front end of the spray shield. A w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com