Electrolytic manganese metal slurrying device

An electrolytic manganese metal pulping technology, applied in electrolytic components, electrolytic process, instruments, etc., can solve problems affecting the quality of electrolytic manganese, poor mixing effect of raw materials, incomplete pulping, etc., to increase the number of collisions and ensure quality , enhance the effect of the zombification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

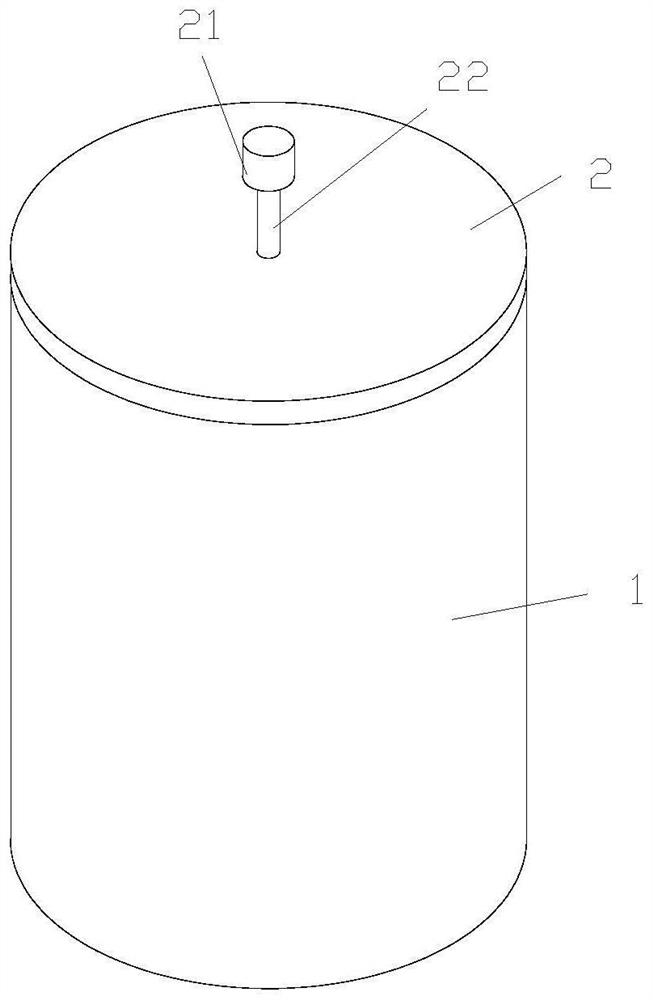

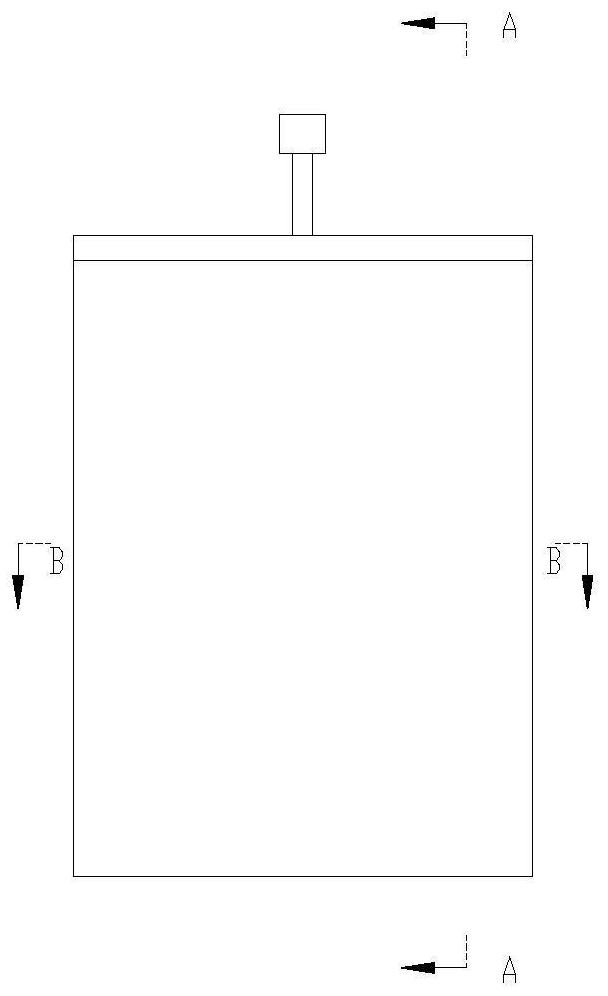

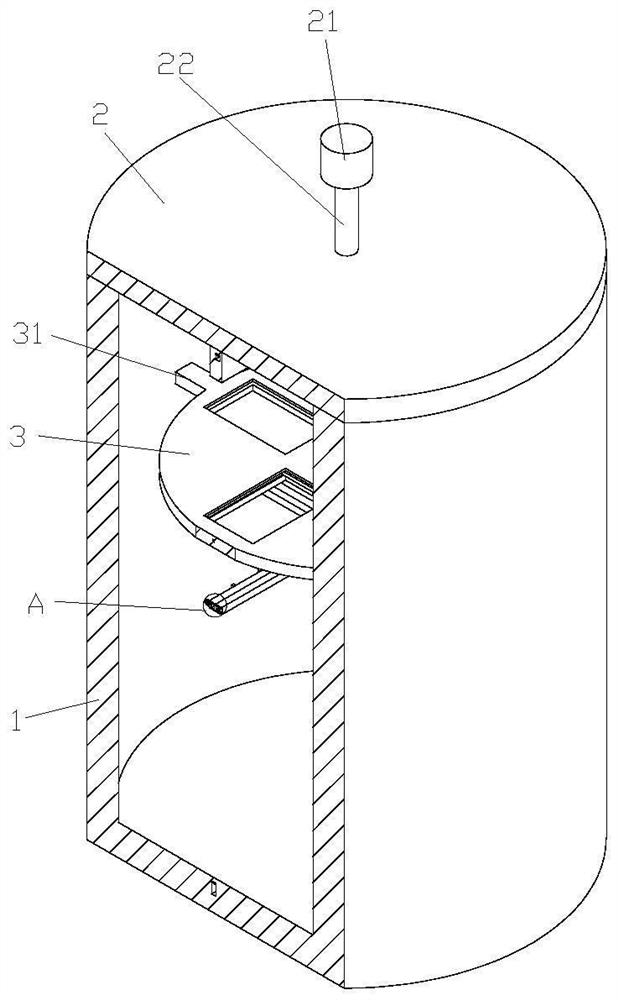

[0044] Such as Figure 1-28 As shown, an electrolytic manganese metal slurrying device includes a barrel body 1 and a cover plate 2 arranged on the top of the barrel body 1, and the barrel body 1 is provided with a stirring assembly that can stir horizontally or vertically. The cover plate 2 is provided with a motor 21 that matches the stirring assembly, and the barrel body 1 is also provided with a baffle assembly that matches the stirring assembly; when the raw materials are mixed, the stirring assembly is interrupted Vertical stirring and horizontal stirring, the raw materials are stirred from multiple directions, so that the raw materials can produce various movements in the barrel, increase the number of collisions of the raw materials, and at the same time, the raw materials in the barrel can be turned under the action of vertical stirring Material function, turn up the raw materials at the bottom of the barrel to prevent solid particles from settling to the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com