Method for degrading amine curing epoxy resin composite material

A technology for curing epoxy resin and composite materials, which is applied in the field of solid waste recycling, can solve the problems of high toxicity of solvent systems, mild reaction conditions, and difficult recovery of catalysts, etc., and achieve clean surfaces, mild reaction conditions, and no damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

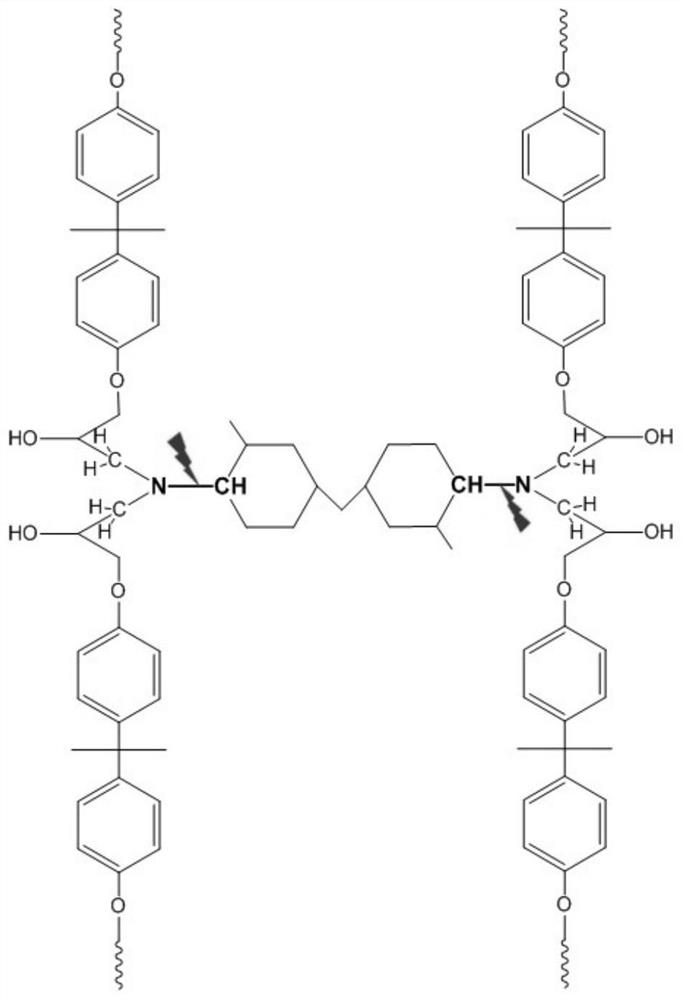

Method used

Image

Examples

Embodiment 1

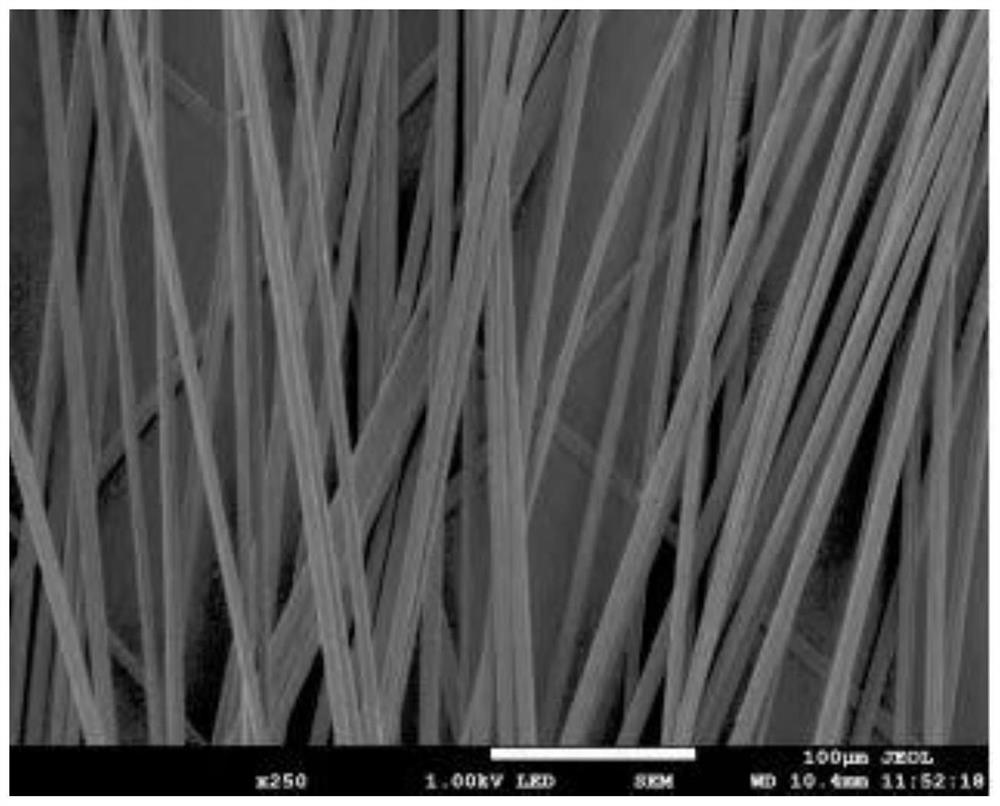

[0028] Add 2.4g of acetic acid and 0.6g of water into the reactor, add 0.15g of calcium nitrate catalyst to form a degradation solution, and then react 1g of carbon fiber reinforced amine-cured epoxy resin with the degradation solution at 140°C for 16h. After the reaction was finished, it was cooled to room temperature, and the calculated degradation rate was 91%. The carbon fiber is directly pulled out from the degradation solution, and the degradation product on the fiber surface is washed out by ethanol, and the clean carbon fiber is obtained after drying, and its tensile strength is measured to be 2.811GPa (96.9% of the original carbon fiber strength); the degradation product asphaltene is passed through Obtained after evaporation of ethanol. The degradation solution and ethanol can be reused.

[0029] The process of the following examples is the same as that of Example 1, and the different raw materials or conditions involved are provided in the form of tabular data.

...

Embodiment 2

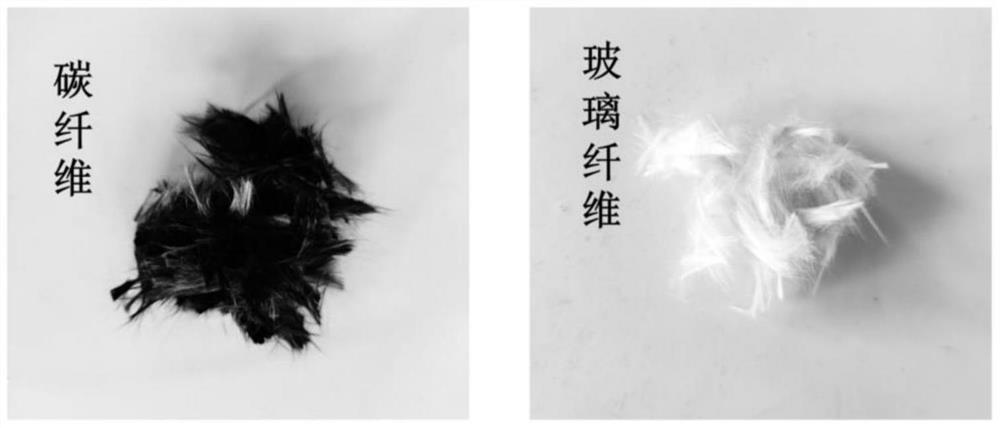

[0031] The reclaimed carbon fiber in embodiment 2 and the reclaimed glass fiber in embodiment 3 are as figure 2 Shown; The electron micrograph of the reclaimed carbon fiber in embodiment 2 is as image 3 Shown; The resin degradation product asphaltenes in embodiment 2 is characterized by nuclear magnetic resonance and the result is as follows Figure 4 shown.

[0032] In summary, it can be seen from Example 12 and Example 13 that when the temperature exceeds the range of 140-220° C., the obtained results are poor. When the temperature is 120 °C, the glass fiber reinforced amine-cured epoxy resin does not degrade; when the temperature is 300 °C, the mechanical properties of the fiber product are greatly lost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com