Temperature-resistant and salt-resistant emulsion type multipolymer for profile control and displacement of offshore oilfield and preparation method thereof

A multi-component copolymer, temperature-resistant and salt-resistant technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as strong technical requirements and difficulty in meeting the thermal stability requirements of control and flooding measures, and achieve significant economic benefits , good market promotion prospects, significant effect of increasing oil and reducing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

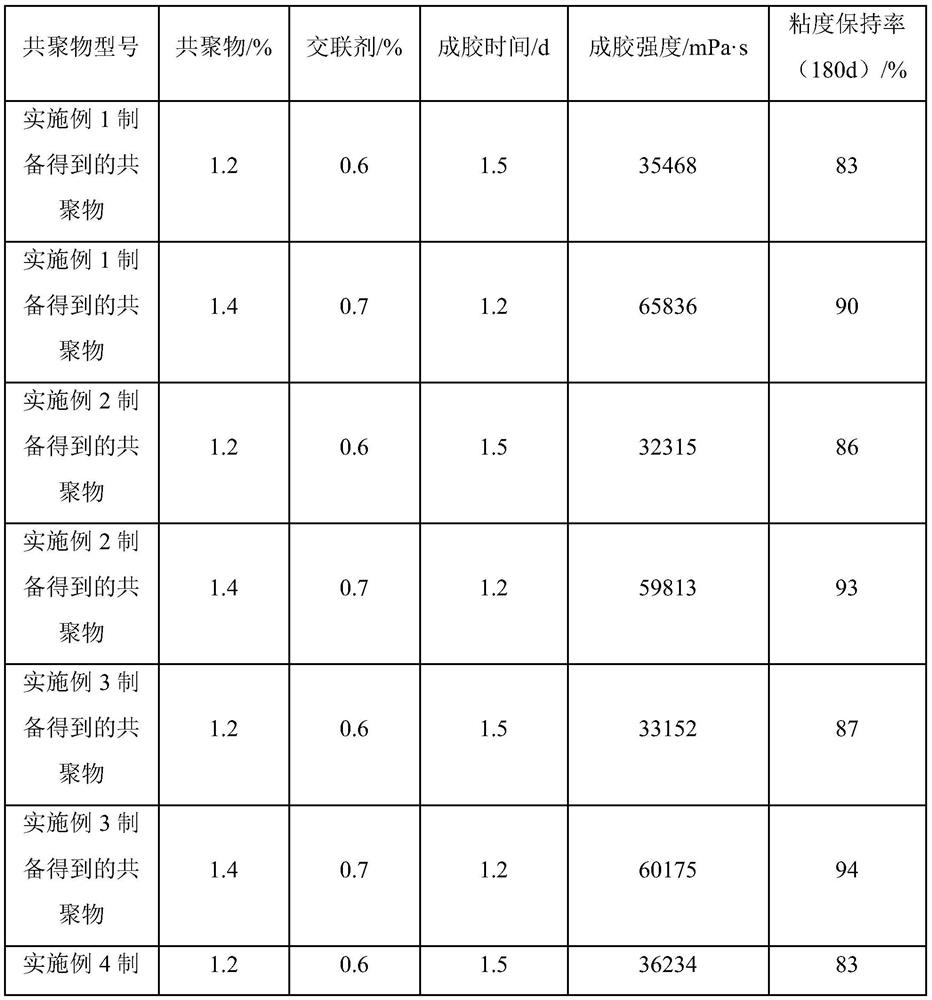

Examples

Embodiment 1

[0027] A temperature-resistant and salt-resistant emulsion-type multi-component copolymer for offshore oil field control and flooding. The raw materials are: acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, white oil, sodium hydroxide, emulsifier, initiator, Phase agent, distilled water.

[0028] Clean the chemical dissolution tank and pipeline, and rinse with distilled water until the conductivity is less than 10μs / cm. Add 200kg of distilled water, 200kg of acrylamide, and 200kg of AMPS into the monomer dissolution tank; add sodium hydroxide to adjust the pH value to 7; control the temperature to 15°C. Under stirring conditions, add 200kg of white oil to the emulsification tank, add 150kg of emulsifier, turn on the emulsification pump, and emulsify. Under the condition of stirring, transfer the dissolved monomer to the emulsification tank, add 0.5 kg of initiator, and at the same time turn on the reflux of the circulating cooling liquid, and control the temperature wit...

Embodiment 2

[0030] A temperature-resistant and salt-resistant emulsion-type multi-component copolymer for offshore oil field control and flooding. The raw materials are: acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, white oil, sodium hydroxide, emulsifier, initiator, Phase agent, distilled water.

[0031] Clean the chemical dissolution tank and pipeline, and rinse with distilled water until the conductivity is less than 10μs / cm. Add 200kg of distilled water, 100kg of acrylamide, and 300kg of AMPS into the monomer dissolution tank; add sodium hydroxide to adjust the pH value to 7; control the temperature at 15°C. Under stirring conditions, add 200kg of white oil to the emulsification tank, add 150kg of emulsifier, turn on the emulsification pump, and emulsify. Under the condition of stirring, transfer the dissolved monomer to the emulsification tank, add 0.5 kg of initiator, and at the same time turn on the reflux of the circulating cooling liquid, and control the temperature wit...

Embodiment 3

[0033] A temperature-resistant and salt-resistant emulsion-type multi-component copolymer for offshore oil field control and flooding. The raw materials are: acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, white oil, sodium hydroxide, emulsifier, initiator, Phase agent, distilled water.

[0034] Clean the chemical dissolution tank and pipeline, and rinse with distilled water until the conductivity is less than 10μs / cm. Add 200kg of distilled water, 100kg of acrylamide, and 300kg of AMPS into the monomer dissolution tank; add sodium hydroxide to adjust the pH value to 7; control the temperature at 15°C. Under stirring conditions, add 150kg of white oil to the emulsification tank, add 200kg of emulsifier, turn on the emulsification pump, and emulsify. Under the condition of stirring, transfer the dissolved monomer to the emulsification tank, add 0.5 kg of initiator, and at the same time turn on the reflux of the circulating cooling liquid, and control the temperature wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com