Method for recovering nicotinic acid in industrial wastewater

A technology of industrial waste water and recovery method, applied in the direction of organic chemistry, etc., can solve the problems of harsh production conditions, high cost of waste water treatment, low quality of nicotinic acid, etc., and achieve the goal of reducing the loss of nicotinic acid, improving the color and luster, and improving the safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] a. First, put 10L of niacin wastewater in a reaction kettle, heat it under vacuum and concentrate until the niacin content reaches 200g / L.

[0030] b. Take 150g of concentrated waste water and directly acidify to pH 3.7, directly add activated carbon of 5% of the total mass of concentrated niacin, add 360g of purified water to dissolve, mix well, heat and boil for 30min.

[0031] c. Suction filtration while hot to obtain filtrate.

[0032] d. The filtrate was allowed to stand at room temperature, and then filtered with suction.

[0033] e. Wash the filter cake of the above step d twice with water, and the amount of water is 4 times of that of the filter cake to obtain the wet product E1.

[0034] f. The wet product E1 obtained from the above step e was vacuum-dried (90°C, -0.09mpa) to obtain high-purity nicotinic acid finished product E2: 18.2g.

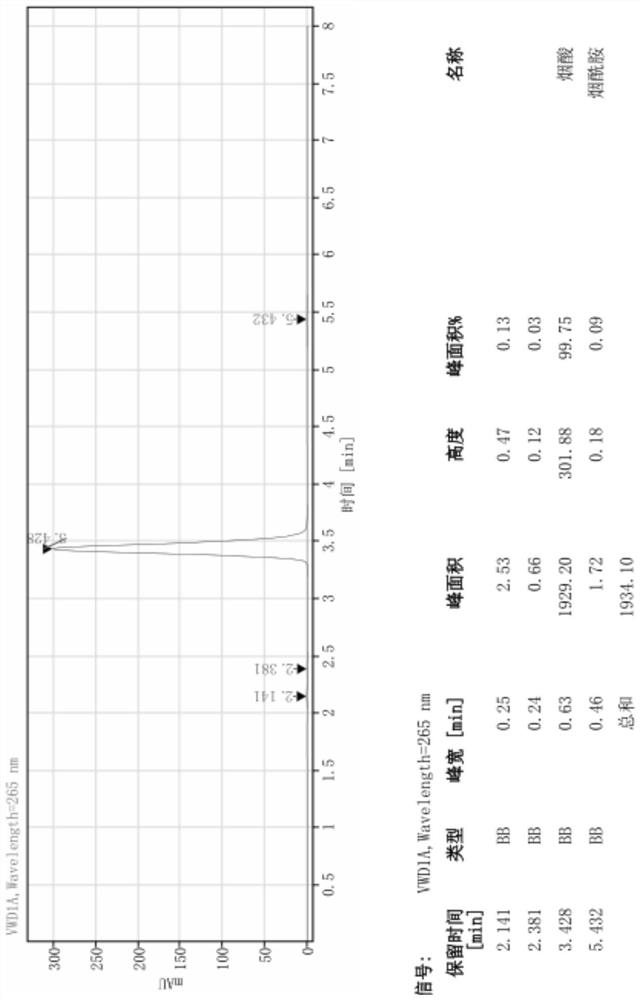

[0035] as table 1 and figure 1 As shown, in this embodiment, high-purity niacin with a niacin content of 99.73% was final...

Embodiment 2

[0039] a. First, put 10L of nicotinic acid waste water in a reaction kettle, vacuumize and heat to concentrate to a nicotinic acid content of 120g / L.

[0040] b. Take 150g of concentrated waste water and directly acidify to pH 3.7, directly add 5% activated carbon of the total mass of concentrated niacin, add 300g of purified water to dissolve, mix well, heat and boil for 30min.

[0041] c. Suction filtration while hot to obtain filtrate.

[0042] d. The filtrate was allowed to stand at room temperature, and then filtered with suction.

[0043] e. Wash the filter cake of the above step d twice with water, and the amount of water is 4 times of that of the filter cake to obtain the wet product E1.

[0044] f. The wet product E1 was obtained from the above step e, and then vacuum-dried (90°C, -0.09mpa) to obtain high-purity nicotinic acid finished product E2: 11.3g.

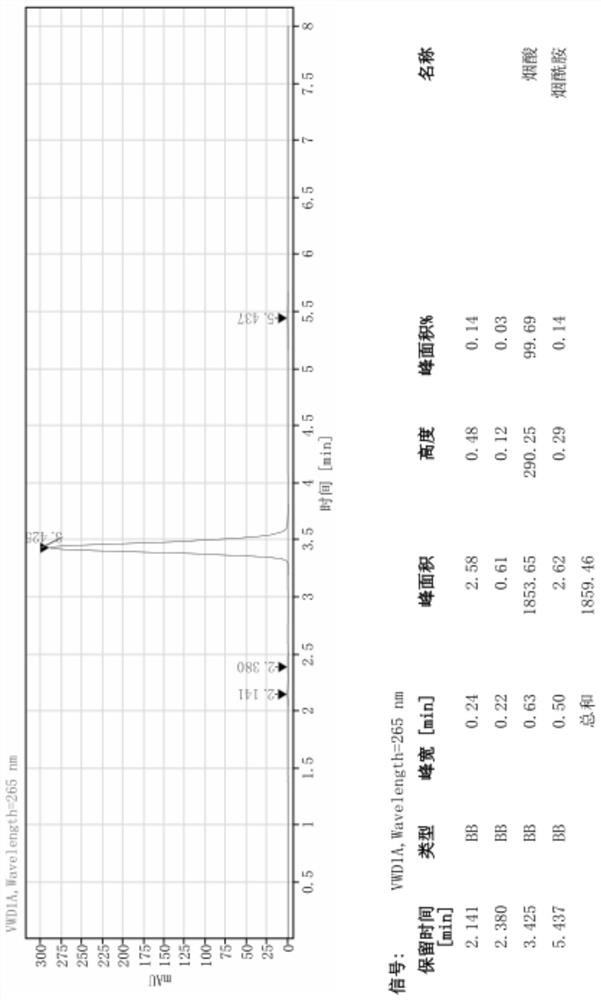

[0045] as table 2 and figure 2 As shown, in this embodiment, high-purity niacin with a niacin content of 99.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com