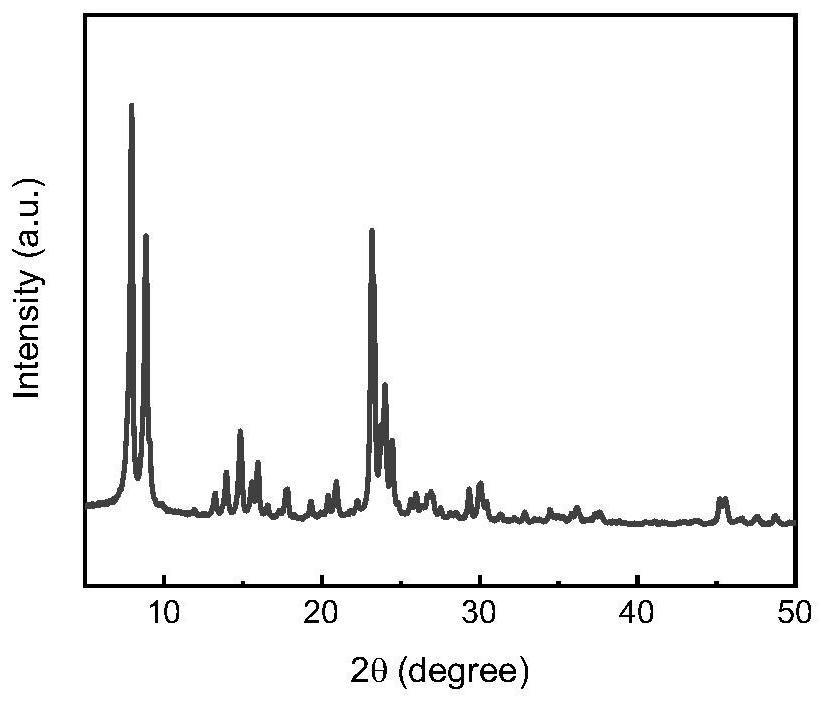

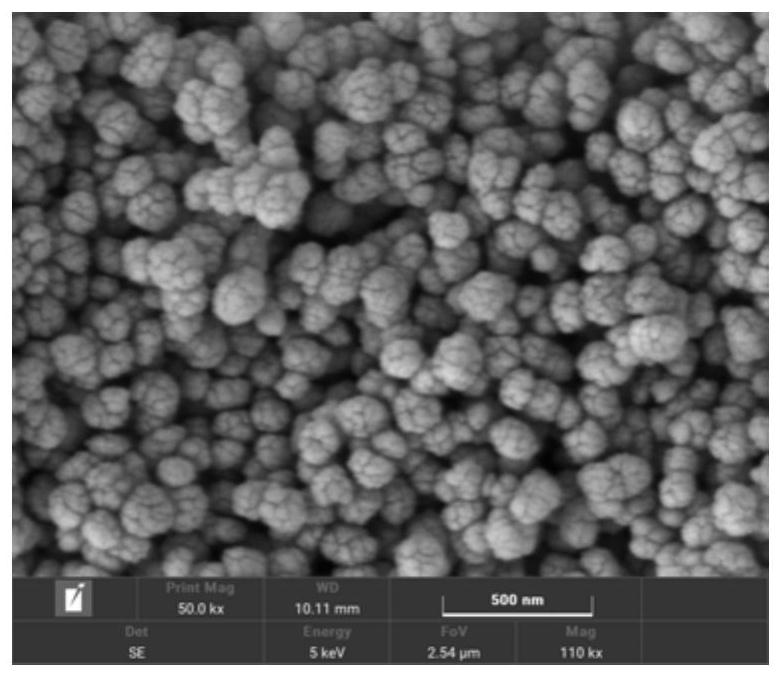

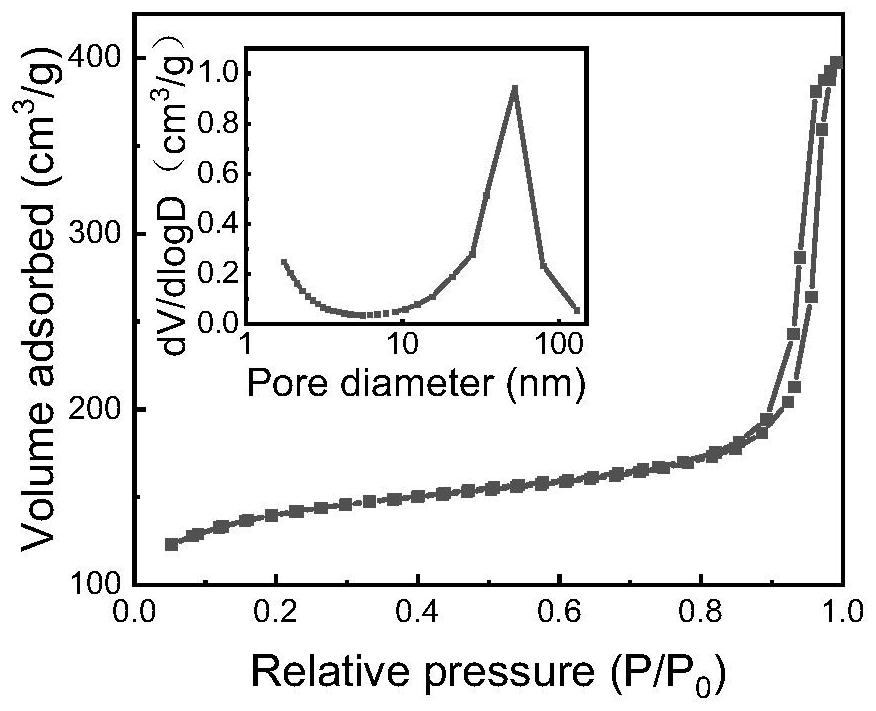

Preparation method of hierarchical pore nano TS-1 molecular sieve

A TS-1, multi-level pore technology, applied in the direction of nanotechnology, crystalline aluminosilicate zeolite, etc., can solve the problems of high production cost of TS-1 molecular sieve, green micropore channel limitation, etc., to reduce synthesis cost, The effect of high crystallinity and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Activation of diatomite: 20.00 g of natural diatomite raw soil was weighed and calcined at 800° C. for 4 hours to obtain activated diatomite.

[0044] (2) Impurity removal of diatomite: add activated diatomite to 1mol / L sulfuric acid solution at a mass ratio of 1:5 and mix, stir at 80°C (stirring speed is 600rpm) for 6h and then filter, and the obtained filter cake is washed to neutral , Modified diatomite can be obtained after drying at 100°C.

[0045] (3) Preparation of molecular sieve: Mix 0.84g of modified diatomite with 40.0g of deionized water, then add 0.52g of NaOH and 6.5g of TPAOH and stir for 30min to obtain A solution, slowly add 0.49g of TBOT into 2.64g of IPA and stir evenly Solution B was obtained; then solution B was slowly added dropwise to solution A to obtain an initial gel, stirred in a water bath at 70°C for 2 hours, then transferred to a reaction kettle lined with polytetrafluoroethylene, and crystallized at 170°C for 72 hours. After the cryst...

Embodiment 2

[0048] (1) Activation of diatomite: 20.00 g of natural diatomite raw soil was weighed and calcined at 600° C. for 6 hours to obtain activated diatomite.

[0049] (2) Impurity removal of diatomite: add activated diatomite to 0.1mol / L sulfuric acid solution at a mass ratio of 1:2 and mix, stir at 40°C (stirring speed is 300rpm) for 8 hours and then filter, and the obtained filter cake is washed to neutral The modified diatomite can be obtained after drying at 100°C.

[0050] (3) Preparation of molecular sieve: Mix 0.84g of modified diatomite with 40.0g of deionized water, then add 0.52g of NaOH and 6.5g of TPAOH and stir for 30min to obtain A solution, slowly add 0.49g of TBOT into 2.64g of IPA and stir evenly Obtain solution B; then slowly add solution B dropwise to solution A to obtain an initial gel, stir in a water bath at 70°C for 2 hours, then transfer to a reaction kettle lined with polytetrafluoroethylene, and crystallize at 140°C for 96 hours. After the crystallization...

Embodiment 3

[0053] (1) Activation of diatomite: 20.00 g of natural diatomite raw soil was weighed and calcined at 1000° C. for 2 hours to obtain activated diatomite.

[0054] (2) Impurity removal of diatomite: add activated diatomite to 2mol / L sulfuric acid solution at a mass ratio of 1:10, mix, stir at 95°C (stirring speed is 900rpm) for 1h, and then filter, and the obtained filter cake is washed to neutral , Modified diatomite can be obtained after drying at 100°C.

[0055] (3) Preparation of molecular sieve: Mix 0.84g of modified diatomite with 40.0g of deionized water, then add 0.52g of NaOH and 6.5g of TPAOH and stir for 30min to obtain A solution, slowly add 0.49g of TBOT into 2.64g of IPA and stir evenly Solution B was obtained; then solution B was slowly added dropwise to solution A to obtain an initial gel, stirred in a water bath at 70°C for 2 hours, then transferred to a reactor lined with polytetrafluoroethylene, and crystallized at 200°C for 48 hours. After the crystallizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com