Hard alloy indexable taper drill and machining method thereof

A cemented carbide and taper technology, used in metal processing equipment, manufacturing tools, milling machine equipment, etc., can solve the problems of narrow use range, poor taper drill hardness, increased use cost, etc., to improve service life, easy to replace, improve The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

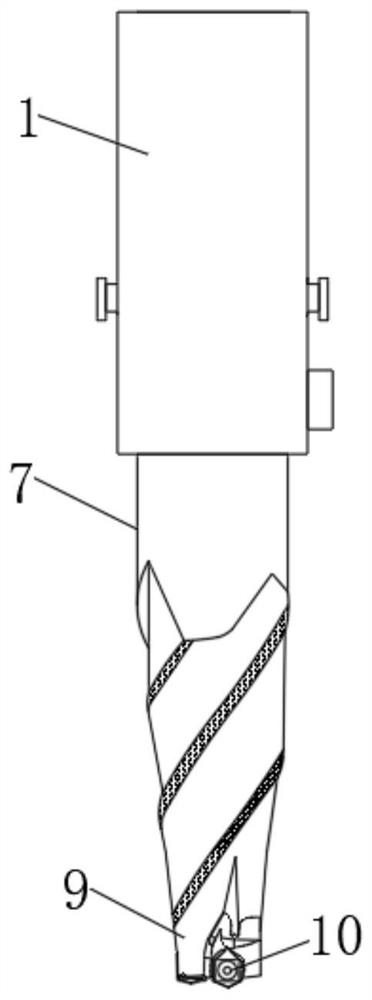

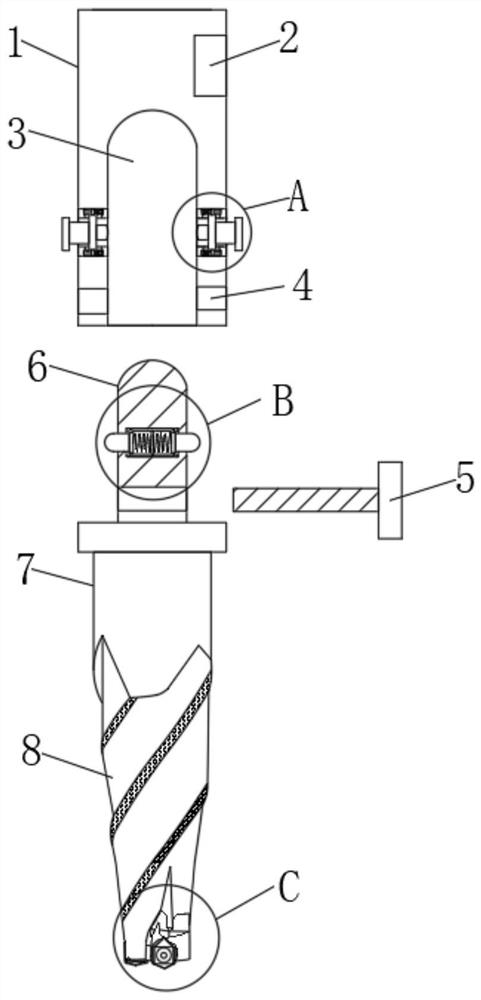

[0038] see Figure 1~7 , a cemented carbide indexable taper drill, including

[0039] The drill pipe 1 has a clamping groove 2 fixed on one side of the side wall, and a positioning groove 3 is fixed inside the center of its lower end, and a threaded hole 4 is provided through the side walls on both sides of the positioning groove 3;

[0040] The drill bit 7 has a positioning column 6 fixedly installed at the center of its upper end, and a through hole matching the threaded hole 4 is provided through the lower side of the positioning column 6;

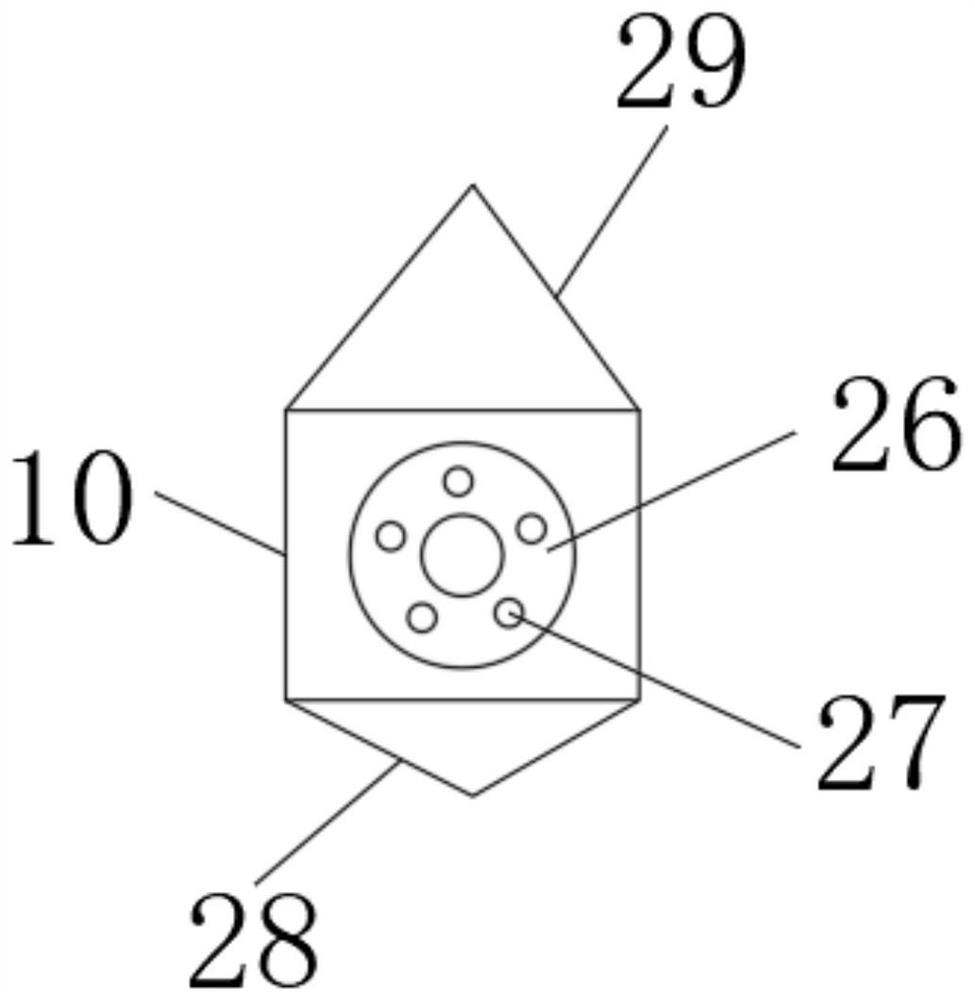

[0041] The tool seat 9 is fixedly mounted on the lower end of the drill bit 7, and its two opposite sides are respectively provided with installation grooves 25, and the middle position of the installation groove 25 is provided with a plurality of annularly distributed positioning holes 30;

[0042] The blade 10 is provided with a mounting disc 26 on its surface, and the mounting disc 26 is annularly provided with a positioning bolt 27...

Embodiment 2

[0047] see Figure 1~7 , a cemented carbide indexable taper drill, including

[0048] The drill pipe 1 has a clamping groove 2 fixed on one side of the side wall, and a positioning groove 3 is fixed inside the center of its lower end, and a threaded hole 4 is provided through the side walls on both sides of the positioning groove 3;

[0049] The drill bit 7 has a positioning column 6 fixedly installed at the center of its upper end, and a through hole matching the threaded hole 4 is provided through the lower side of the positioning column 6;

[0050] The tool seat 9 is fixedly mounted on the lower end of the drill bit 7, and its two opposite sides are respectively provided with installation grooves 25, and the middle position of the installation groove 25 is provided with a plurality of annularly distributed positioning holes 30;

[0051] The blade 10 is provided with a mounting disc 26 on its surface, and the mounting disc 26 is annularly provided with a positioning bolt 27...

Embodiment 3

[0056] A cemented carbide indexable taper drill 8, the hole processing method of the taper drill is as follows:

[0057] A. First connect the drill pipe 1 and the drill bit 7, insert the positioning column 6 provided on the drill bit 7 into the positioning groove 3 provided inside the drill pipe 1, and then clamp it on the side wall of the drill pipe 1 with the clamping rod 22 In the clamping groove provided above, the preliminary fixation of the drill rod 1 and the drill bit 7 is realized, and then the fastening bolt 5 is passed through the threaded hole 4 and the through hole, thereby realizing the fixation between the drill rod 1 and the drill bit 7;

[0058] B, the blade 10 is installed, and the blade 10 is fixed to the mounting groove 25 through the cooperation between the installed mounting plate 26, the positioning hole 30 and the positioning bolt 27;

[0059] C. Install the taper drill, connect the taper drill to the machine tool through the set clamping groove 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com