Flue gas denitration and deacidification process and flue gas denitration and deacidification integrated system

A flue gas and denitration technology, applied in gas treatment, chemical instruments and methods, emission prevention, etc., can solve problems such as excessive ammonia escape, and achieve the effects of avoiding secondary pollution, low cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) The untreated flue gas produced by waste incineration in a power plant, the flue gas volume (hourly average value) is 56000Nm 3 , where the NOx (hourly average) content is 350mg / Nm 3 , lead the flue gas to be treated to the target space of the boiler, spray ammonia water into the target space of the boiler, the feeding rate of ammonia water (hourly average value) is 30L / h, and the temperature in the target space is 900°C to obtain denitrification flue gas, denitrification The ammonia content (hourly average) in the flue gas is 25mg / Nm 3 ;

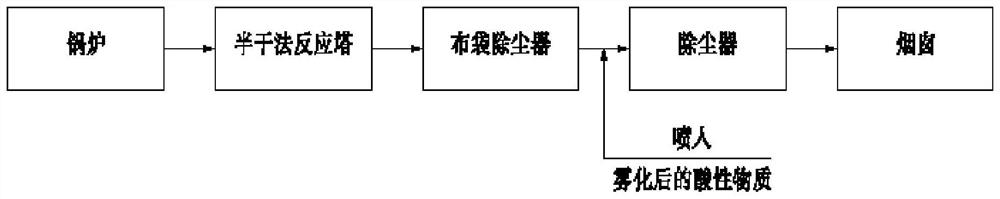

[0052] (2) Drain the denitrification flue gas to the semi-dry reaction tower to react with slaked lime for deacidification treatment to obtain deacidification flue gas, and then divert the deacidification flue gas to the first dust collector for dust removal treatment to obtain Dust removal flue gas from flue;

[0053] (3) Spray the atomized acetic acid solution in the smoke outlet flue, the mass concentration of the acetic ac...

Embodiment 2

[0056] (1) The untreated flue gas produced by waste incineration in a power plant, the flue gas volume is 56000Nm 3 (hourly average value), the NOx content of which is 350mg / Nm 3 (hourly average value), the flue gas to be treated is diverted to the target space of the boiler, and urea is sprayed into the target space of the boiler. The feeding rate of urea is 35L / h (hourly average value), and the temperature in the target space is 850°C. Flue gas, the ammonia content (hourly average value) in the denitrification flue gas is 27mg / Nm 3 ;

[0057] (2) Drain the denitrification flue gas to the semi-dry reaction tower to react with slaked lime for deacidification treatment to obtain deacidification flue gas, and then divert the deacidification flue gas to the first dust collector for dust removal treatment to obtain Dust removal flue gas from flue;

[0058] (3) Spray atomized acetic acid solution in the smoke outlet flue, the mass concentration of the acetic acid solution is 10%...

Embodiment 3

[0061] (1) The untreated flue gas produced by waste incineration in a power plant, the flue gas volume (hourly average value) is 56000Nm 3 , where the NOx content (hourly average value) is 350mg / Nm 3 , lead the flue gas to be treated to the target space of the boiler, spray ammonia water into the target space of the boiler, the feeding rate of ammonia water (hourly average value) is 25L / h, and the temperature in the target space is 950°C to obtain denitrification flue gas, denitrification The ammonia content (hourly average) in the flue gas is 22mg / Nm 3 ;

[0062] (2) Drain the denitrification flue gas to the semi-dry reaction tower to react with slaked lime for deacidification treatment to obtain deacidification flue gas, and then divert the deacidification flue gas to the first dust collector for dust removal treatment to obtain Dust removal flue gas from flue;

[0063] (3) spray the hypochlorous acid solution after the atomization in the smoke outlet flue, the mass conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com