SCR and SNCR denitrification system collaborative control method for pulverized coal power station boiler

A power plant boiler and collaborative control technology, which is applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of large fluctuation, high thermal NOx emission value, and high ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The content of the present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments.

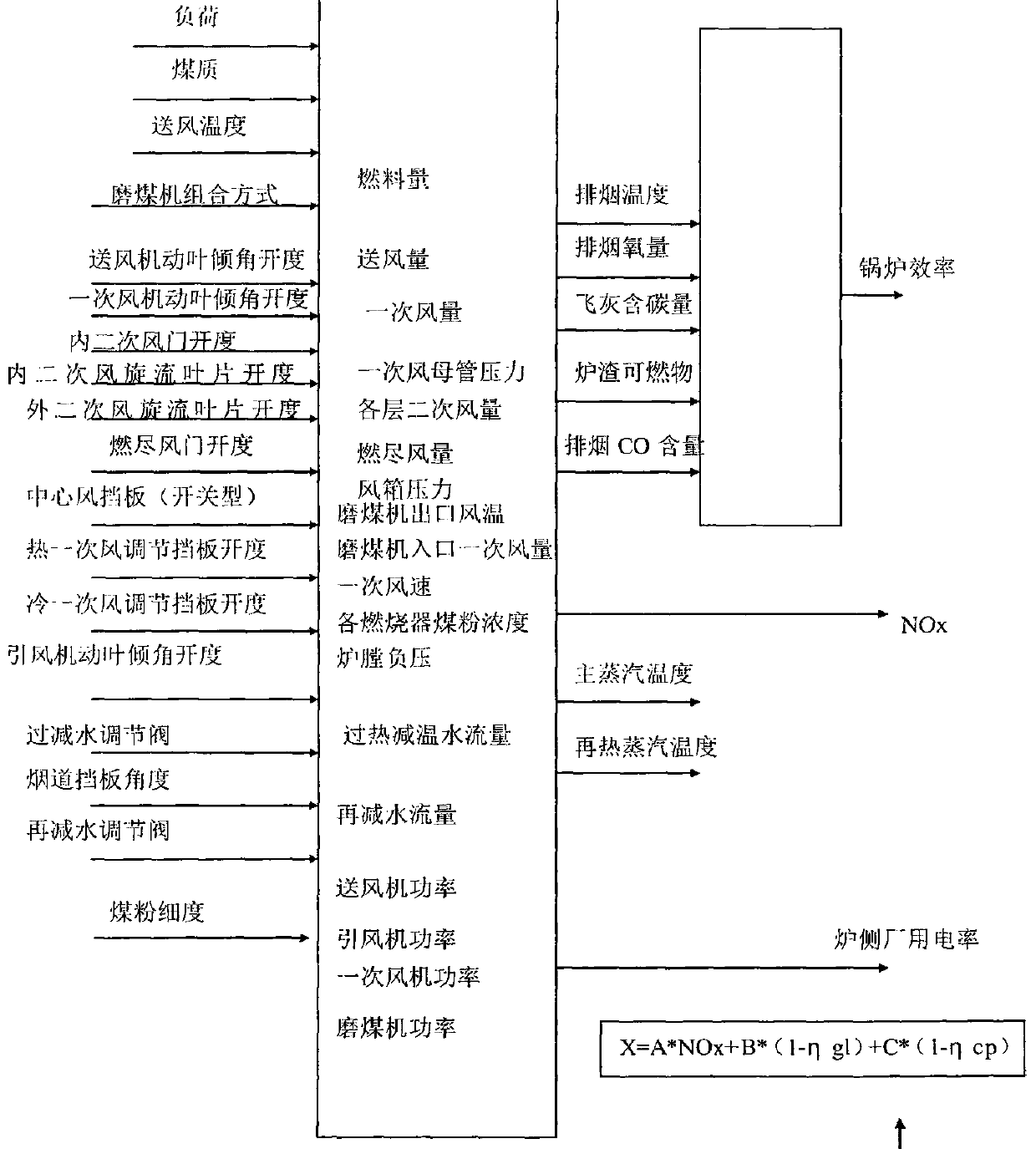

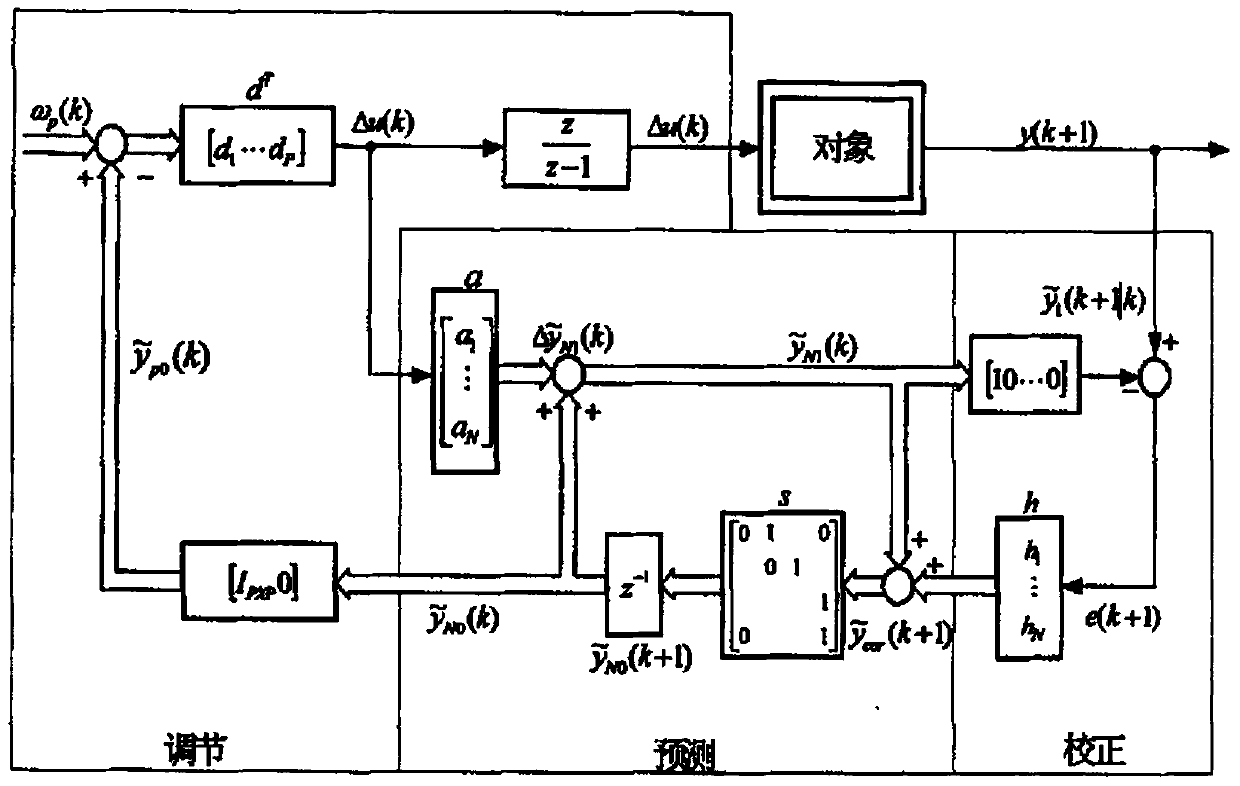

[0072]A collaborative control method for SCR and SNCR denitrification systems of pulverized coal power plant boilers according to the present invention includes combustion optimization control and denitration ammonia injection control optimization, and the specific operation control method is as follows:

[0073] Combustion and SNCR optimization control

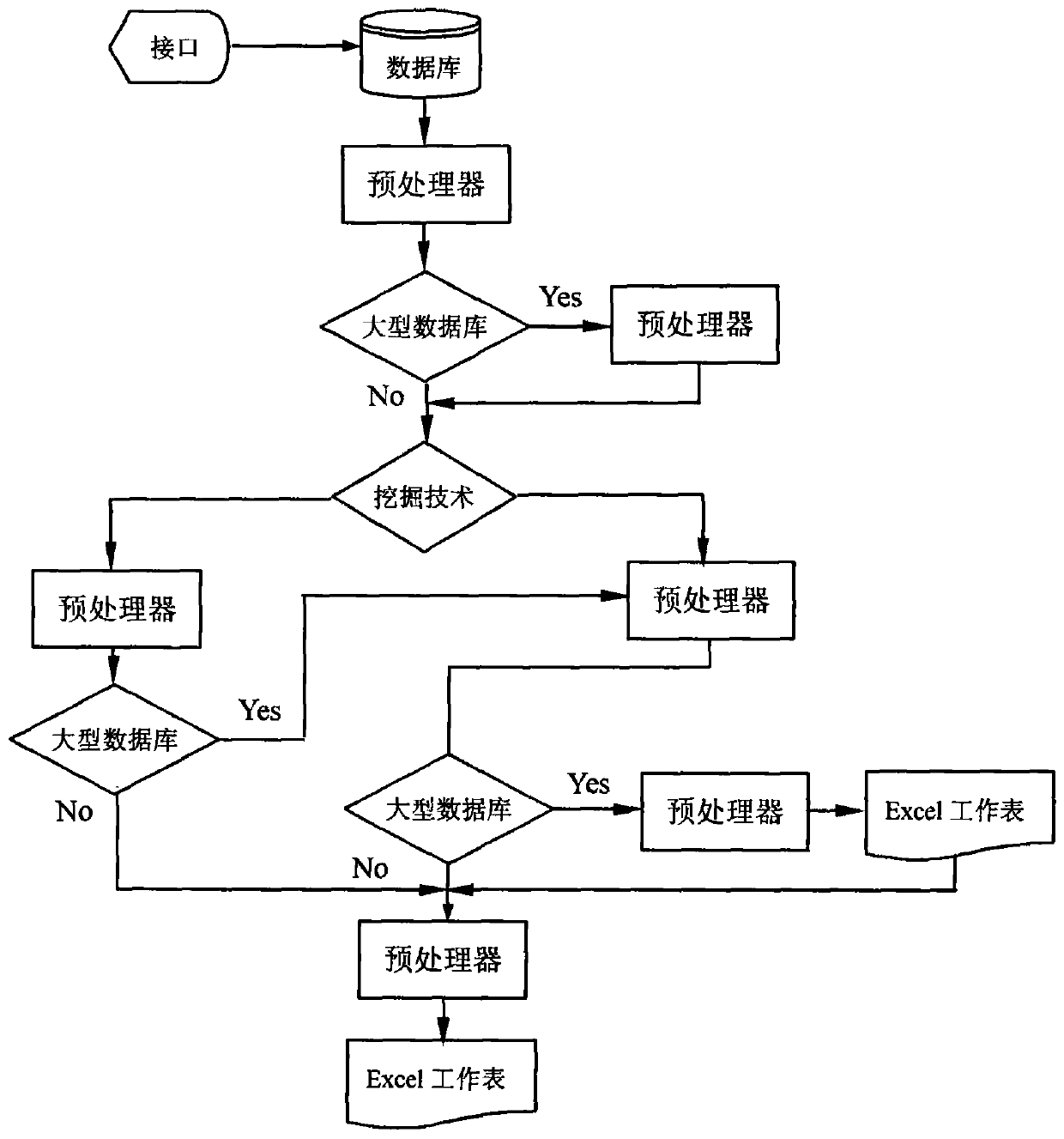

[0074] Such as figure 1 and figure 2 As shown, data measurement and acquisition: Obtain data from the unit unit, including pressure, speed, internal flow of fluid machinery, oxygen amount at the furnace outlet, combustion structure parameters, and parameter data of the coal mill operation combination mode.

[0075] Data cleaning: Specifically, the SIS system collects data according to a certain frequency. The set cleaning rate is 2, and 1 minute can be used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com