Stator and motor

A stator and motor technology, applied in the directions of transportation and packaging, winding, electric components, etc., can solve the problems of difficult assembly, complex connection shape, etc., and achieve the effect of improving the ease of manufacturing and realizing short-pitch winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0021]

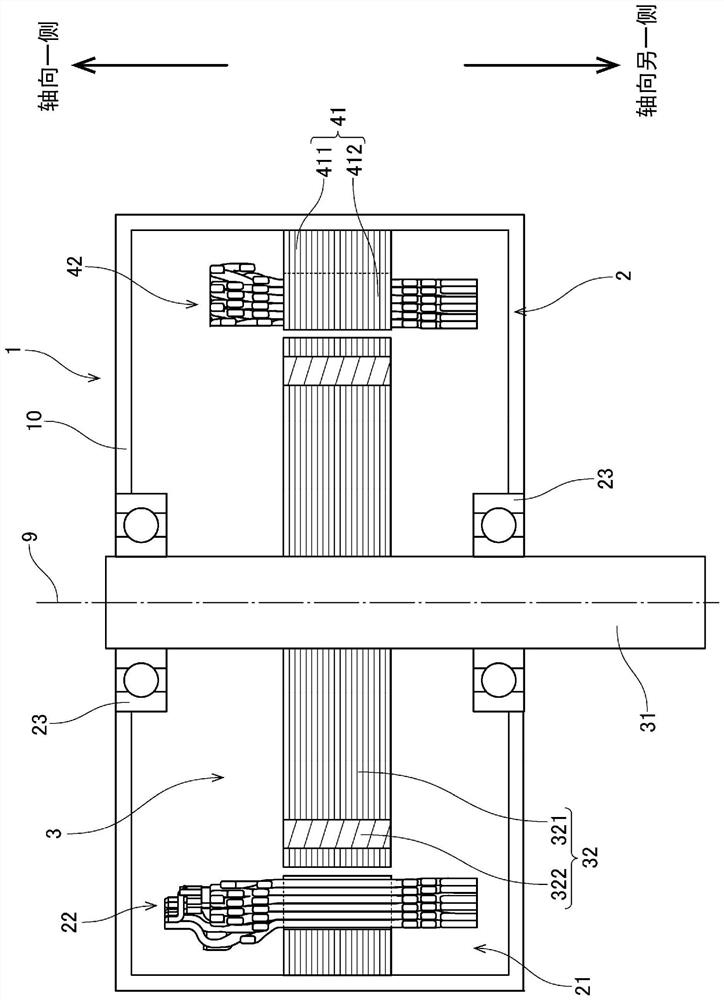

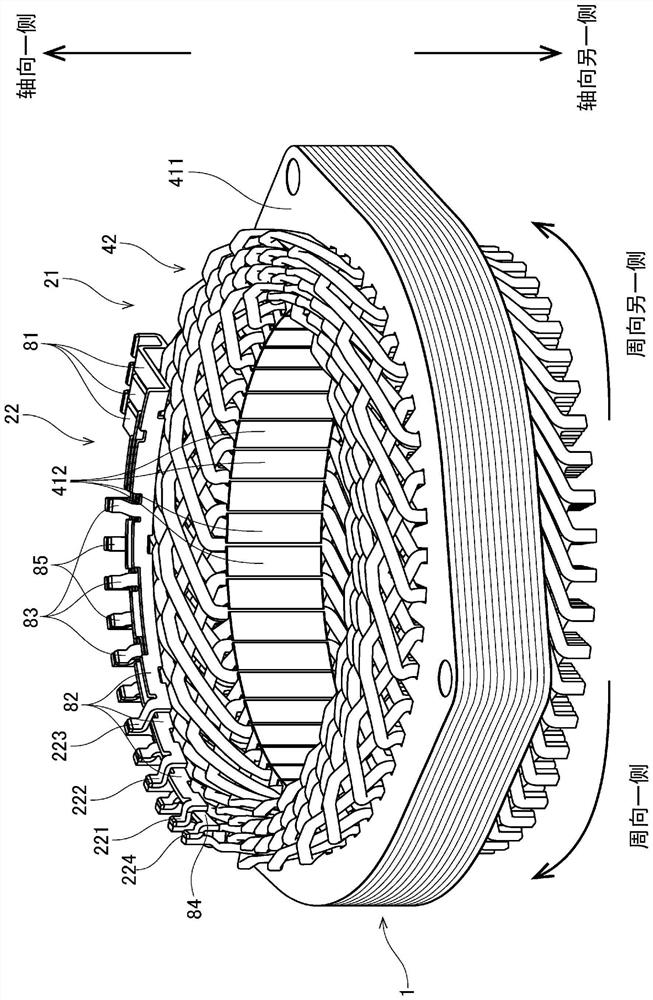

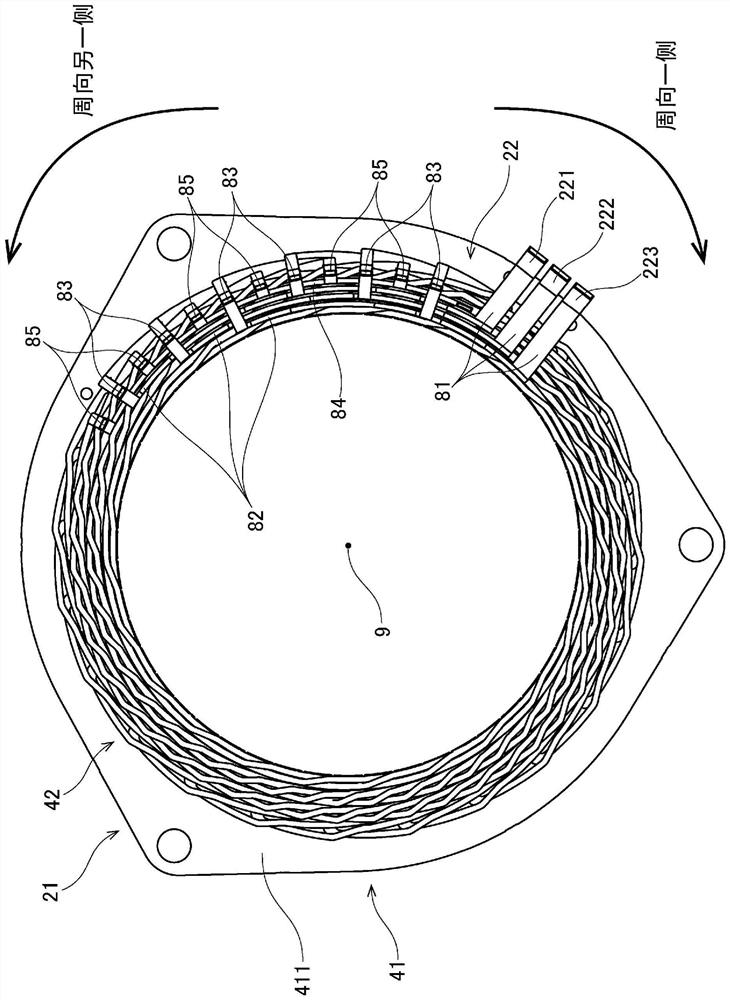

[0022] figure 1 It is a schematic cross-sectional view of the motor 1 having the stator 21 according to the first embodiment of the present invention. figure 2 It is a perspective view of the stator 21 and the bus bar part 22. also, image 3 It is a plan view of the stator 21 and the bus bar part 22 viewed from one side in the axial direction.

[0023] The motor 1 is a traction motor installed in a vehicle such as an electric vehicle or a plug-in hybrid vehicle, and outputs a driving force for driving the vehicle. However, the motor 1 of the present invention may also be a motor for purposes other than a traction motor. For example, it may be a motor that is installed in air blowers, home electric appliances, medical equipment, industrial large equipment, etc., and outputs a driving force.

[0024] Such as figure 1 As shown, the motor 1 has a motor housing 10 , a stationary part 2 and a rotating part 3 . The motor cover 10 is a frame housing at least part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com