Evaporation module for producing concentrate and liquid product manufacturing system comprising same

A technology for liquid products and concentrates, applied in the field of evaporation modules used to produce concentrates and liquid product manufacturing systems including the evaporation modules, can solve problems such as differences and inconsistencies in natural fragrances, reduce the feeling of differences, improve Fragrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

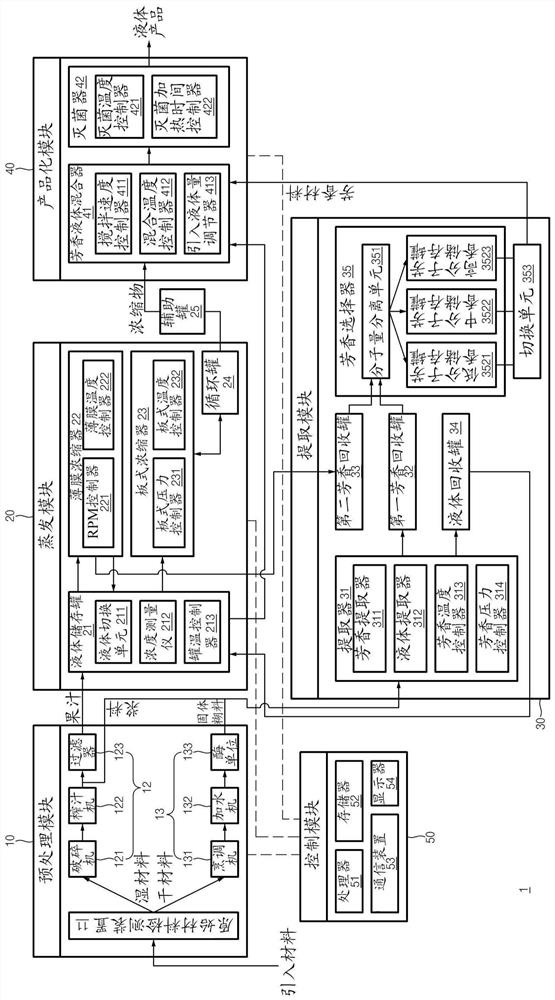

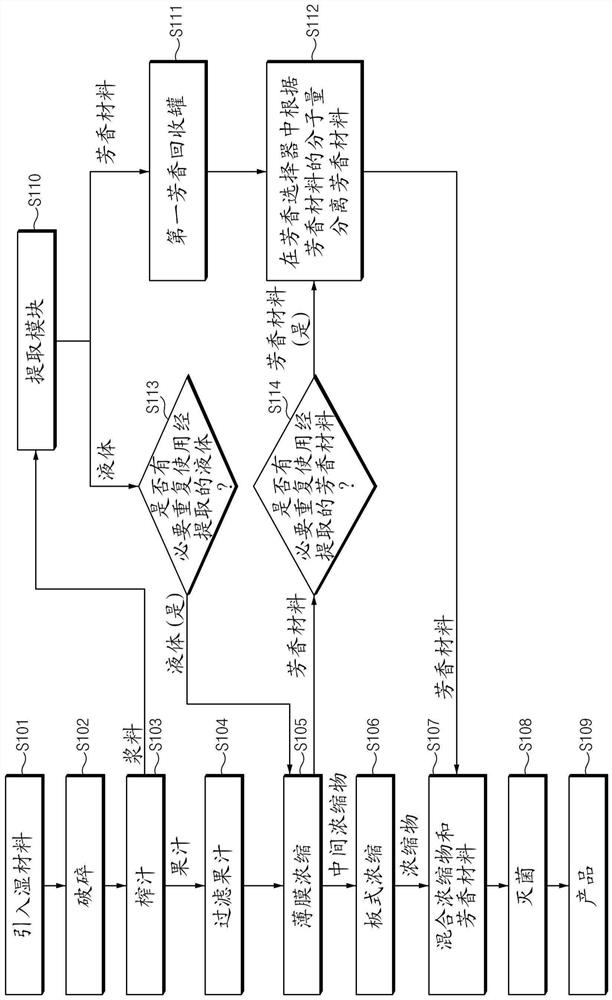

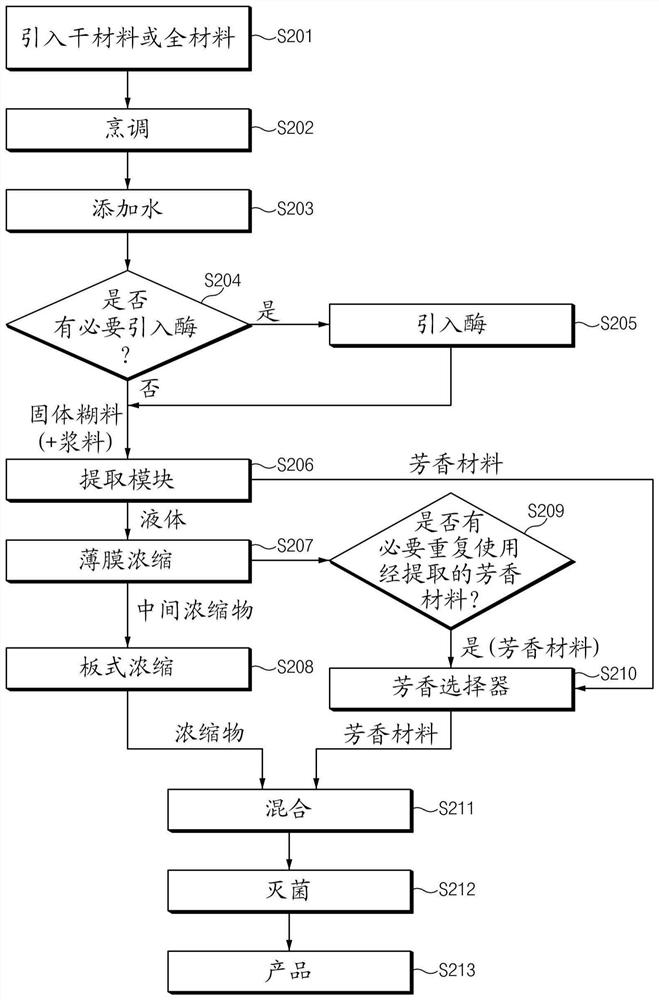

[0020] Hereinafter, some embodiments of the present invention will be described in detail with reference to exemplary drawings. Throughout the specification, it should be noted that even if the same or similar reference numerals are provided in different drawings, they denote the same or similar components. Also, in the following description of the present invention, when a detailed description of known functions and configurations incorporated herein may make the subject matter of the present invention rather unclear, the detailed description will be omitted.

[0021] Also, terms such as first, second, A, B, (a), (b), etc. may be used herein when describing components of the present invention. These terms are provided only to distinguish these components from other components, and the nature, timing, sequence, etc. of these components are not limited by these terms. When it is described that an element is connected, coupled or electrically connected to another element, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com