Connector assembly and plug and socket locking connection structure

A technology of plug, socket and connection structure, which is applied to the parts, connections, and two-part connection devices of connection devices, etc., can solve the problems of large space occupation, inability to meet the requirements of miniaturization of servo motor installation space, etc., so as to reduce the space occupation. Space, realize the effect of miniaturization of installation and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

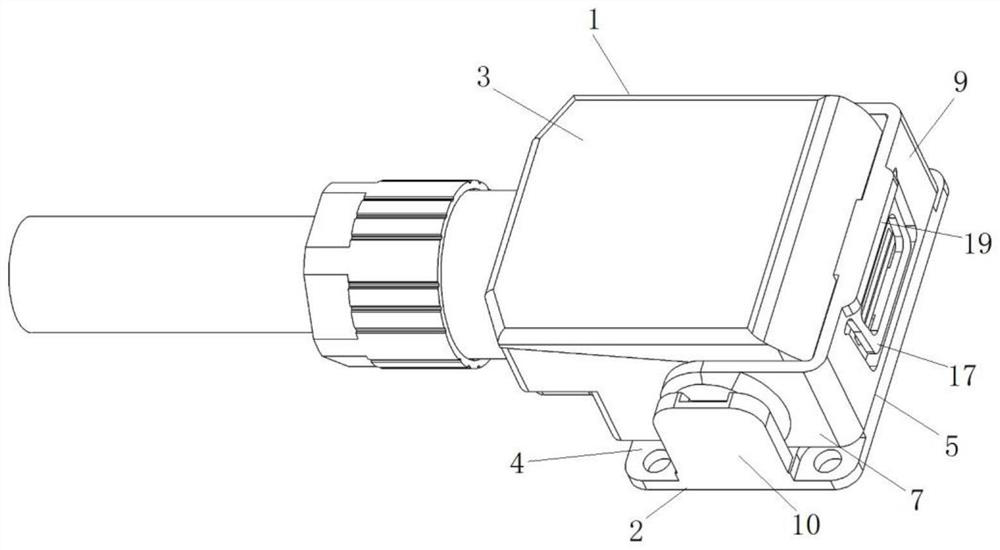

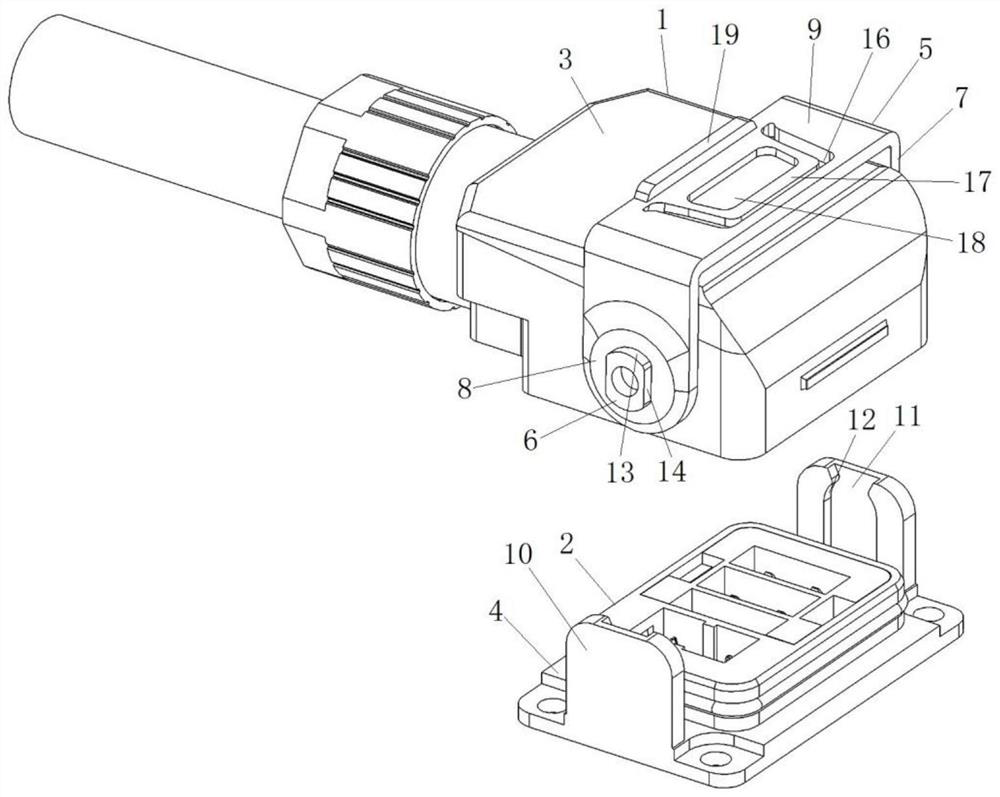

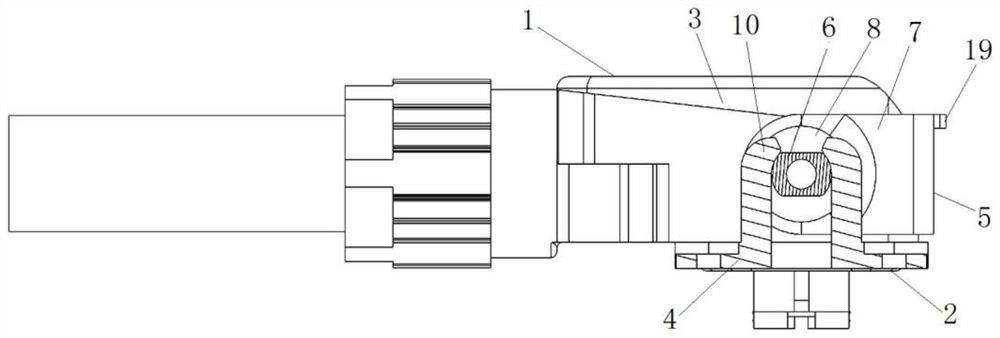

[0071] likefigure 1 and figure 2 As shown, the connector assembly includes a plug 1 and a socket 2. The plug 1 includes a plug housing 3, and the socket 2 includes a socket housing 4. 2 Locking connection structure with locking fit.

[0072] The locking connection structure includes a locking wrench 5 and a locking arm 10 . The locking wrench 5 is rotated and assembled on the plug housing 3. During the rotation of the locking wrench 5 relative to the plug 1, the locking wrench 5 has a locking position for locking the plug 1 and the socket 2, and also has a function for making the plug 1 and the socket 2 lock together. Unlock bit for socket 2 unlock. Specifically, such as figure 2 and Figure 4 As shown, the locking wrench 5 is a U-shaped structure, and the locking wrench 5 includes a rotating arm 7 formed by two side walls of the U-shaped structure. Extending in the direction perpendicular to the rotation axis, the two rotation arms 7 are provided with through holes cor...

specific Embodiment 2

[0085] The difference with the specific embodiment 1 is that the minor axis dimension of the locking cam is equal to the notch width dimension, and the major axis dimension of the locking cam is smaller than the diameter dimension of the arc groove wall surface. The structure of the groove can also restrict the locking cam from coming out of the locking groove when the plug and socket are inserted in place and the locking wrench is rotated to the locking position, so as to realize the effective locking of the plug and the socket.

specific Embodiment 3

[0087] The difference from the specific embodiment 1 is that the outer contour of the locking cam is elliptical, the locking groove is a circular groove, and in the vertical insertion direction, the locking groove is a through groove, and the notch is facing the insertion direction. The diameter dimension of the circular groove is equal to the major axis dimension of the locking cam, and the notch width dimension is greater than the minor axis dimension of the locking cam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com