Quantitative liquid injection equipment for large-batch lithium batteries

A lithium battery, high-volume technology, used in battery pack parts, electrolyte battery manufacturing, non-aqueous electrolyte battery and other directions, can solve the problems of inability to meet the needs of mass production, low work efficiency, poor injection accuracy, etc. The linkage between them is exquisite, the structure is simplified, and the operation is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

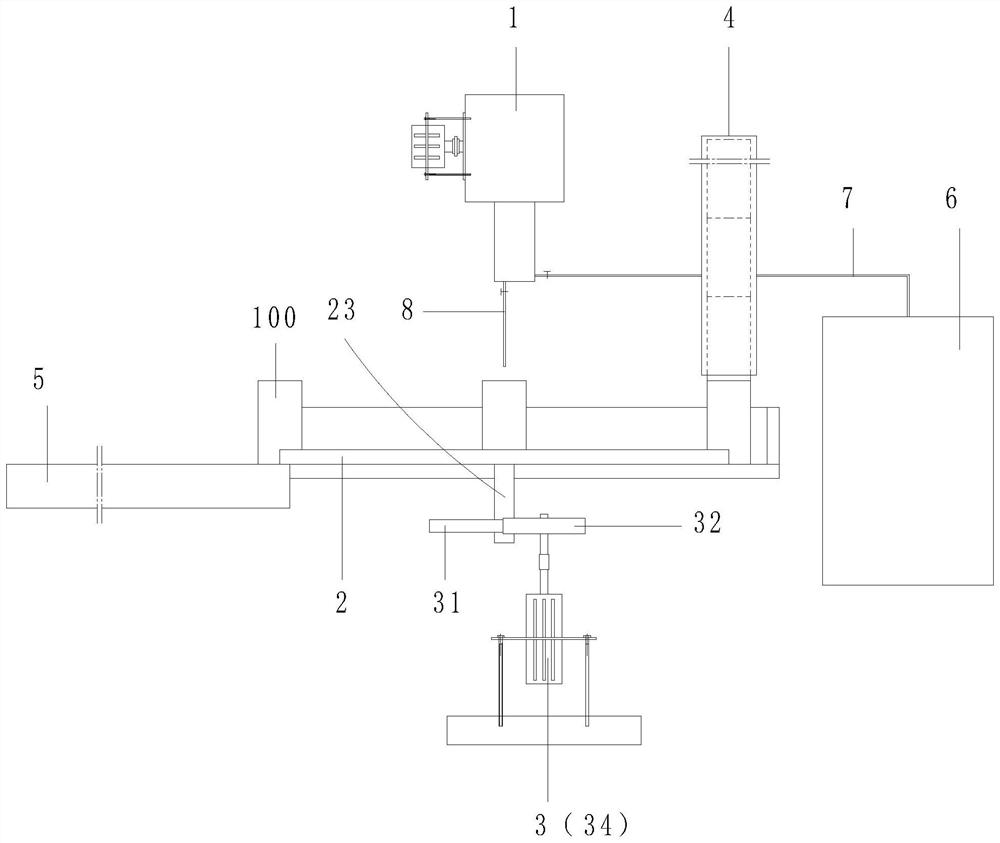

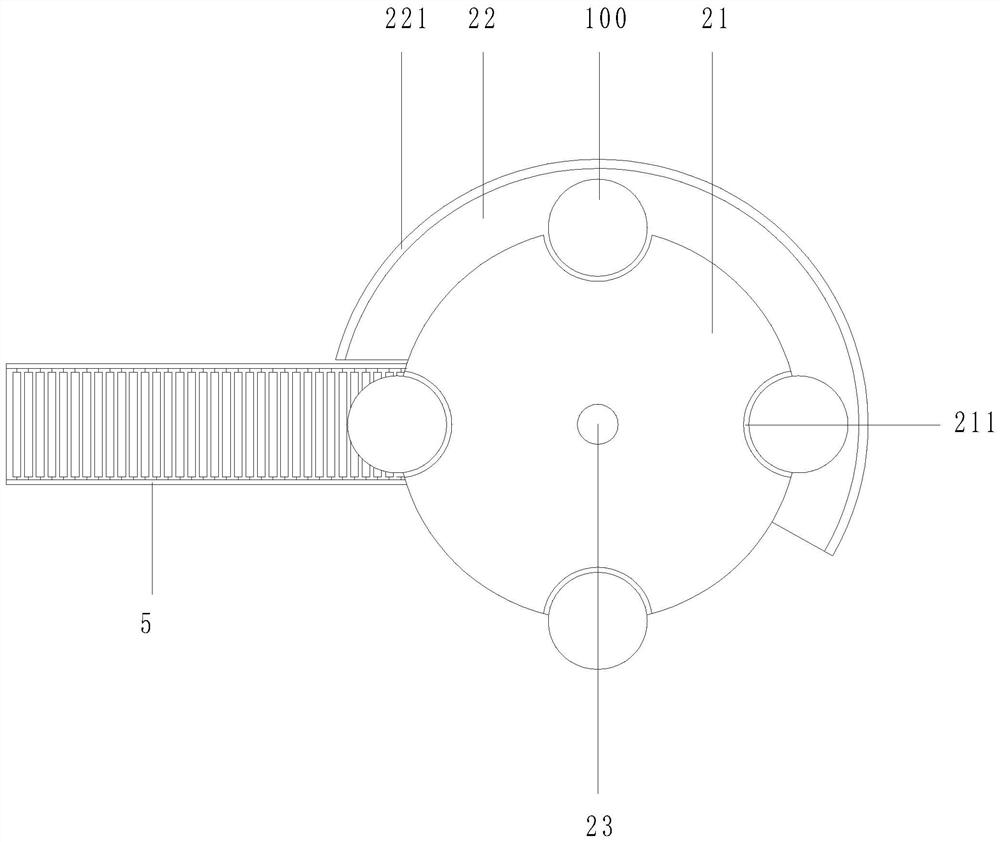

[0024] Such as Figure 1 to Figure 4 As shown, a quantitative liquid injection device for large quantities of lithium batteries includes a liquid injection device 1, an intermittent offset device 2, a drive device 3, a delivery channel 4, a transmission device 5 and an electrolyte container 6, and the liquid injection device 1 is installed On the upper rear side of the intermittent offset device 2, the drive unit 3 is installed below the intermittent offset device 2 and drives the intermittent offset device 2 to rotate intermittently, and the delivery channel 4 is installed on the upper right side of the intermittent offset device 2, and the transmission 5 abuts against the left side of the intermittent deflection device 2, and the electrolyte container 6 is installed on the right side of the intermittent deflection device 2 and communicates with the liquid injection device 1 through a pump body (not shown in the figure) and a conduit 7.

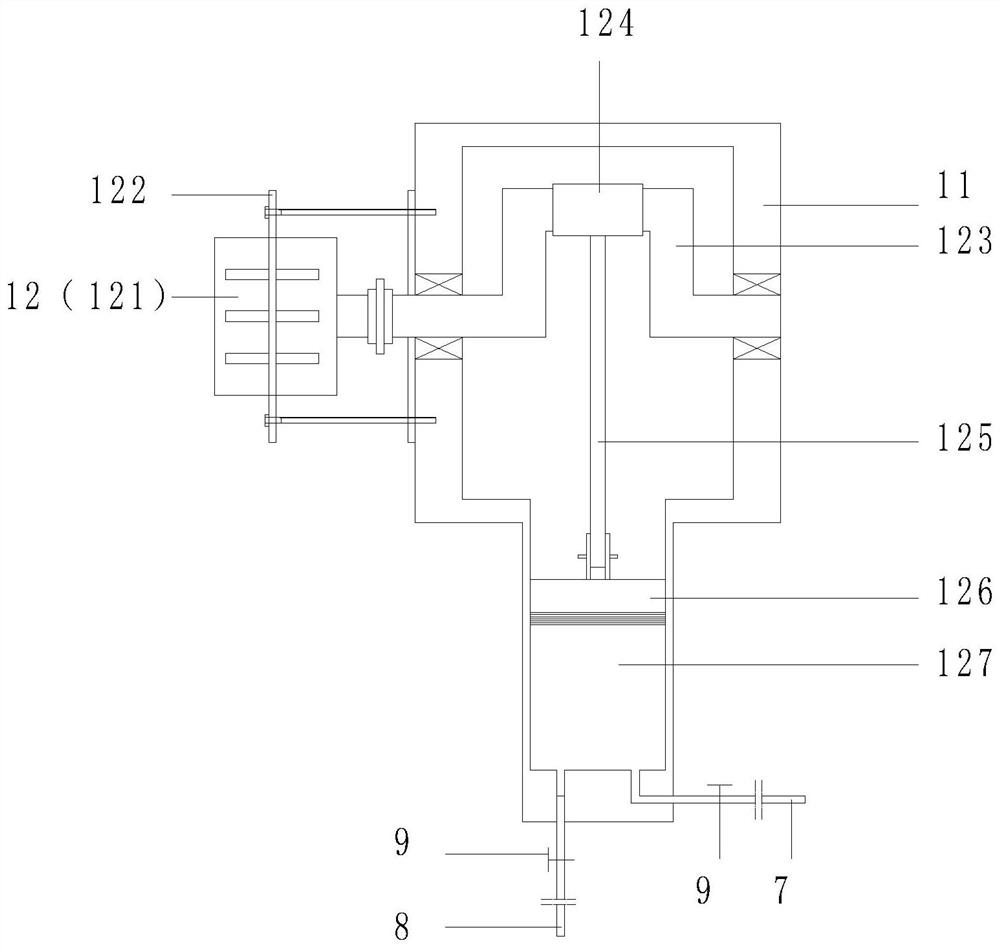

[0025] In this example, if figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com