Soft package material for lithium battery

A technology for lithium batteries and soft packs, applied in lithium batteries, secondary batteries, battery pack components, etc., can solve the problem of not being able to display the actual temperature and curing uniformity of the aluminum-plastic film, and is conducive to product quality control and follow-up. Use, increase toughness, and uniform effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

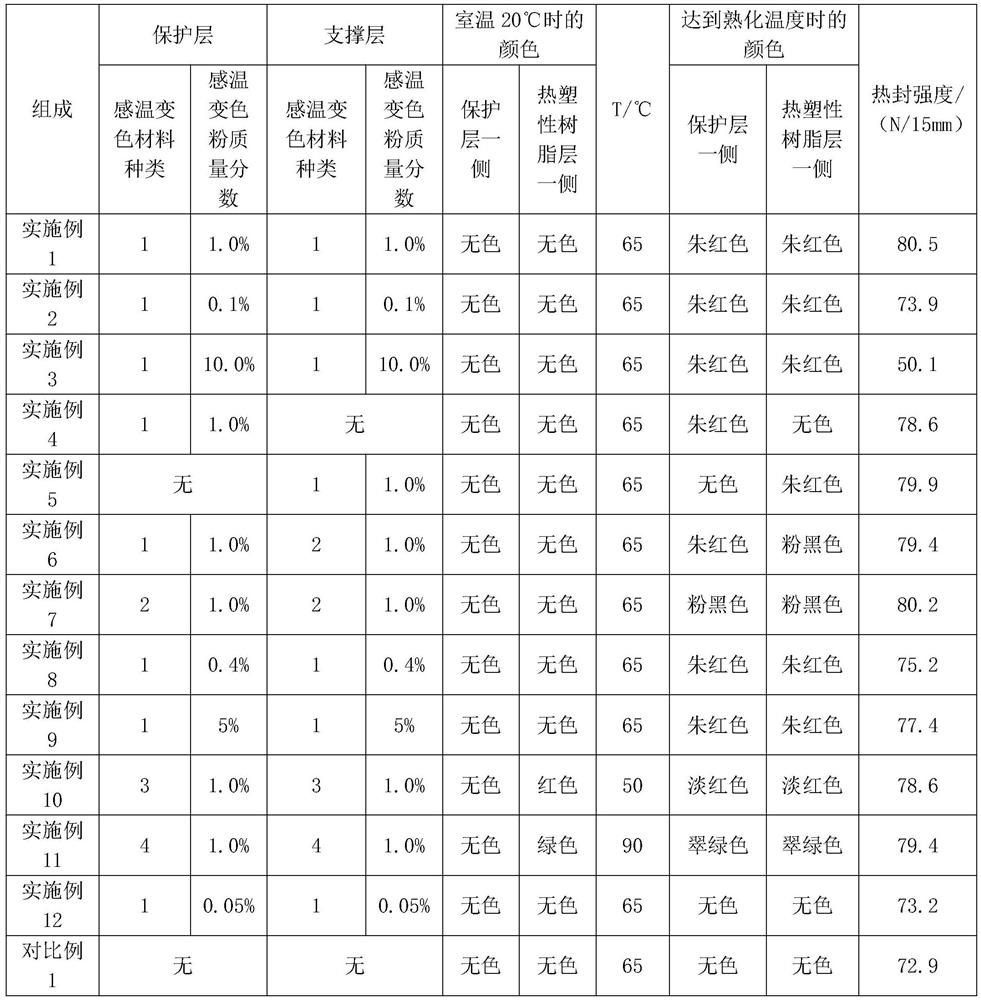

Examples

preparation example Construction

[0038] In another typical embodiment of the present application, a method for preparing a soft package material for a lithium battery is provided, comprising the following steps: (1) providing a metal foil, and performing corrosion-resistant treatment on both sides thereof to obtain the metal foil Foil layer; (2) using the first adhesive layer to compound the protective layer and one side of the metal foil layer with a pressure roll, and aging to obtain a protective layer / first adhesive layer / metal foil layer laminate; ( 3) using the second adhesive layer to press the thermoplastic resin layer and the other side of the metal foil layer of the protective layer / first adhesive layer / metal foil layer laminate to be laminated and aged to obtain the Soft packaging materials for batteries.

[0039] Further, the metal foil is a single-sided light metal foil, which has undergone degreasing treatment.

[0040] Further, the protective layer is laminated with the dark side of the metal f...

Embodiment 1

[0043] The protective layer is a biaxially stretched nylon film with a thickness of 25 μm, and the manufacturer is Xiamen Changsu Industrial Co., Ltd.;

[0044] The first adhesive layer is a two-component polyurethane glue with a thickness of 4 μm and a main solid ratio of 100 / 16. The manufacturer is Japan Toyobo;

[0045] The metal foil layer is made of aluminum foil, which is a single-sided light aluminum foil with a thickness of 40 μm and has been treated with phosphochromate anticorrosion. The manufacturer is Henan Mingtai Aluminum Co., Ltd.;

[0046] The second adhesive layer is a two-component acid-modified polyolefin resin glue with a thickness of 4 μm and a main solid ratio of 100 / 12. The manufacturer is Japan Toyobo;

[0047] The thickness of the thermoplastic resin layer is 40 μm, the third adhesive layer and the heat-sealing layer are polyolefin elastomer (2% by mass fraction) as the dispersed phase, and polypropylene resin (98% by mass fraction, melting point 110-1...

Embodiment 2

[0052] Both the protective layer and the support layer contain 0.1% of thermochromic material 1, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com