Vehicle power inductor with high heat-conducting property and assembly method

A technology of power inductors and assembly methods, which is applied in transformer/inductor cooling, transformer/inductor components, inductor/transformer/magnet manufacturing, etc., can solve the problems of poor heat dissipation performance of inductors, achieve small flux leakage window, and improve Effects of durability and small conductor cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

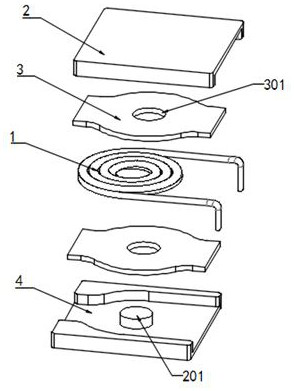

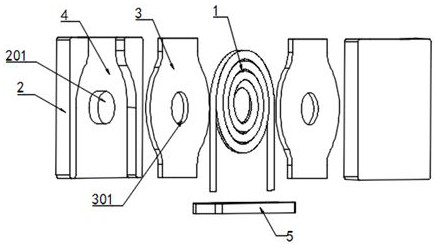

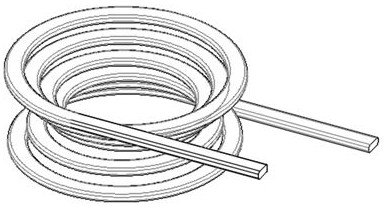

[0056] refer to Figure 1-5 , a power inductor for vehicles with high thermal conductivity, including a magnetic core 2, two magnetic cores 2 are provided, a coil 1 is provided between the two magnetic cores 2, the coil 1 is in a flat spiral structure, and the coil 1 is cabled It is a flat structure, and the inner side of the two magnetic cores 2 that is attached to the external heat sink is embedded with a heat conduction sheet 3. The coil 1 has a small operating current and low power loss. The heat conduction sheet 3 is not installed in the inductor, and the center of the heat conduction sheet 3 A through slot 301 is opened, and the side of the magnetic core 2 close to the coil 1 is provided with a clamping slot 4, and the middle position of the clamping slot 4 is fixedly connected with the magnetic core 2 with a cylindrical limiting column 201, and the limiting column 201 is connected with the magnetic core 2. The heat conducting sheet 3 and the coil 1 are fitted in a slidi...

Embodiment 2

[0072] refer to Figure 1-5 , a power inductor for vehicles with high thermal conductivity, including a magnetic core 2, two magnetic cores 2 are provided, a coil 1 is arranged between the two magnetic cores 2, the coil 1 is in a flat spiral structure, and the coil 1 is cabled It is a flat structure, and the inner side of the two magnetic cores 2 that is attached to the external heat sink is embedded with a heat conduction sheet 3. The coil 1 has a small operating current and low power loss. The heat conduction sheet 3 is not provided in the inductance, and the center of the heat conduction sheet 3 A through slot 301 is opened, and the side of the magnetic core 2 close to the coil 1 is provided with a clamping slot 4, and the middle position of the clamping slot 4 is fixedly connected with the magnetic core 2 with a cylindrical limiting column 201, and the limiting column 201 is connected to the magnetic core 2. The heat conducting sheet 3 and the coil 1 are fitted in a slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com