A Crack Measuring Endoscope

An endoscope, crack technology, applied in measurement devices, optical testing flaws/defects, image enhancement, etc., can solve the problems of inability to measure the length and width of cracks, low illumination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0122] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

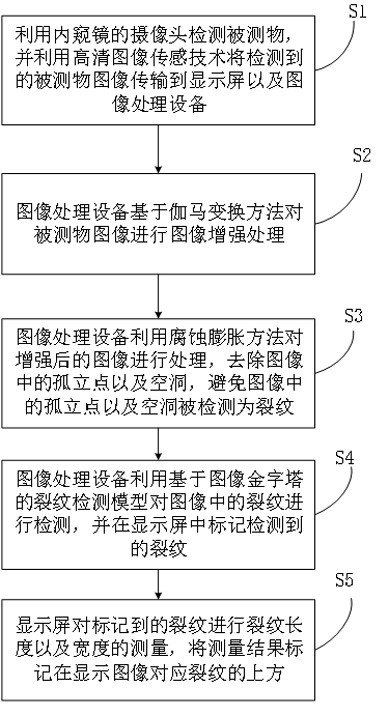

[0123] S1: Use the camera of the endoscope to detect the measured object, and use the high-definition image sensing technology to transmit the detected image of the measured object to the display screen and image processing equipment.

[0124] In the step S1, the camera of the endoscope is used to detect the measured object, including:

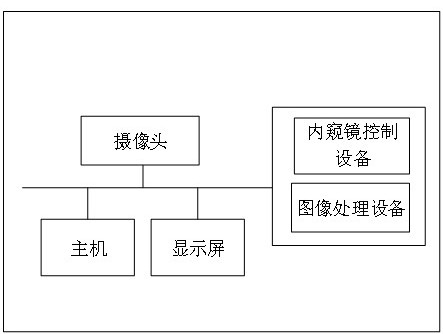

[0125] The endoscope control device in the endoscope detection system is used to control and select the photo-taking or video-recording function of the endoscope, and control the light intensity of the endoscope camera to obtain a static image or dynamic video of the measured object. The diameter of the probe is Φ8mm, the pixel is 1 million, the depth of field is 8-80mm, and the visual direction is direct view; in a specific embodiment of the present invention, if a static image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com