Novel asphalt mixture rut test piece demolding equipment

An asphalt mixture and rutting technology is applied in the field of new-type asphalt mixture rutting test piece demoulding equipment, which can solve the problems of affecting work efficiency and quality, loosening of mold connection parts, time-consuming and labor-intensive, etc. The effect of improving efficiency and simplifying the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

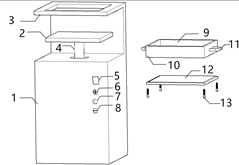

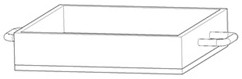

[0021] like figure 1 and figure 2 As shown, a new type of asphalt mixture rutting specimen demoulding equipment consists of a matching demoulding machine (1), lifting column (2), lifting platform (3), stripping plate (4), power switch (5) , up button (6), stop button (7), down button (8), anti-adhesive coating (9), rut test piece mold side plate (10), heat insulation handle (11), rut test piece mold side plate Bottom plate (12) and fixing bolts (13), the rutting test piece mold side plate (10) and the rutting test piece mold side plate bottom plate (12) can be fixed by fixing bolts (13), thereby forming an open container, the open The inner wall of the mouth container is provided with an anti-sticking coating (9).

[0022] When using:

[0023] Unscrew the four fixing bolts (13), take off the side plate bottom plate (12) of the rutting test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com