Low-grade thermal compound driving refrigerating system for large data center

A low-grade heat and refrigeration system technology, applied in solar heating systems, solar collectors using working fluids, refrigerators, etc., can solve the problems of low waste heat and waste heat, difficult to use, etc. Efficiency, the effect of expanding the use of categories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

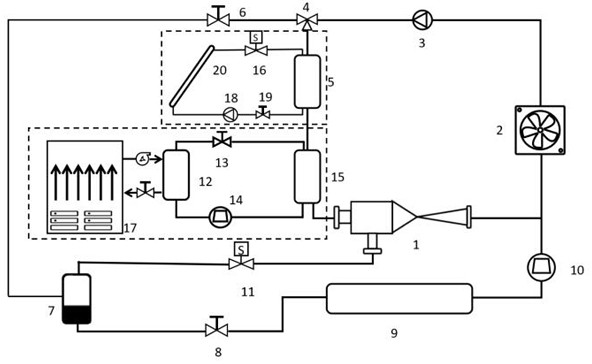

[0028] see figure 1 , figure 1 The low-grade thermal composite drive refrigeration system for large data centers includes ejector compression refrigeration units, data center waste heat warming units and solar thermal collection units.

[0029] When the solar radiation is sufficient and the heat production of the data center is stable, the jet compression refrigeration unit, the waste heat heating unit of the data center and the solar heat collection unit are started at the same time. At this time, the power of the variable speed compressor is low or does not need to be started.

[0030] The ejector compression refrigeration unit includes ejector 1, condenser 2, pump 3, three-way valve 4, heat exchanger I5, throttle valve I6, gas-liquid separator 7, throttle valve II8, evaporator I9, variable speed compressor 10 , Solenoid valve I11 and heat exchanger II15. The specific connection method is: the outlet of ejector 1, the outlet of variable speed compressor 10 are connected to...

Embodiment 2

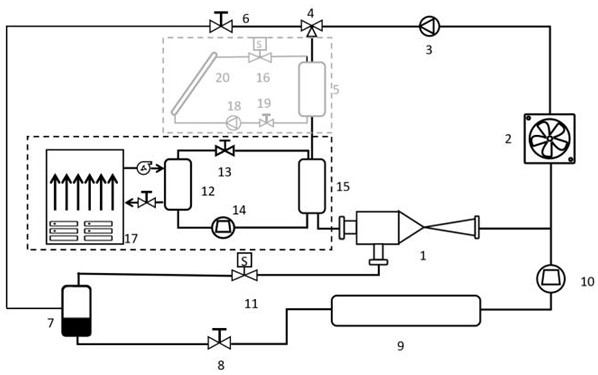

[0037] see figure 2 , figure 2 The low-grade thermal composite drive refrigeration system for large data centers includes ejector compression refrigeration units and data center waste heat warming units.

[0038] When the solar radiation is weak due to the alternation of day and night and the weather changes, and there is no normal heating of the solar collector unit, the solenoid valve II16 is closed, and the solar collector unit stops working. The waste heat heating unit of the data center provides a low-grade heat source, variable speed compression Auxiliary power supply to maintain the stable operation of the system.

[0039] In the data center waste heat heating unit, the refrigerant in the evaporator II12 changes from a liquid state to a gas state to absorb the low-grade waste heat generated by the data center, and the refrigerant leaving the evaporator II12 enters the compressor 14 to compress high-temperature and high-pressure gas, The gas enters the heat exchanger...

Embodiment 3

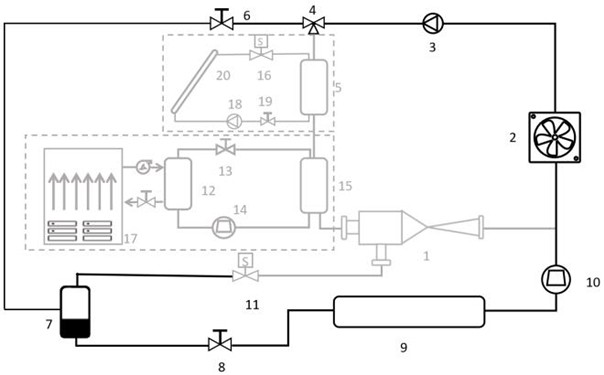

[0042] see image 3 , image 3 The low-grade heat compound drive refrigeration system used in large data centers includes ejector compression refrigeration units.

[0043] When the available low-grade energy is insufficient, the first and third ports of the three-way valve 4 are opened, the second port is closed, the solar heat collection unit and the waste heat heating unit of the data center are stopped, and the ejector 1 is stopped. This embodiment is equivalent to In a traditional vapor compression refrigeration system, the variable speed compressor 10 provides electric energy to maintain refrigeration.

[0044] The invention combines the characteristics of the injector with simple structure and no moving parts, and can widely utilize low-grade energy. The waste heat temperature of the data center is low, less than 70°C, but the heat production is large and stable. The heat is collected by the heat pump system. For use in jet compression refrigeration systems. Realize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com