Material returning control system and method of circulating fluidized bed boiler

A technology of circulating fluidized bed and control system, which is applied in the direction of fluidized bed combustion equipment, fuel for combustion in a molten state, and combustion methods, etc. etc., to achieve the effect of reducing operation and maintenance costs, solving the hidden dangers of failure and downtime, and avoiding shutdown of furnace or emergency repair of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

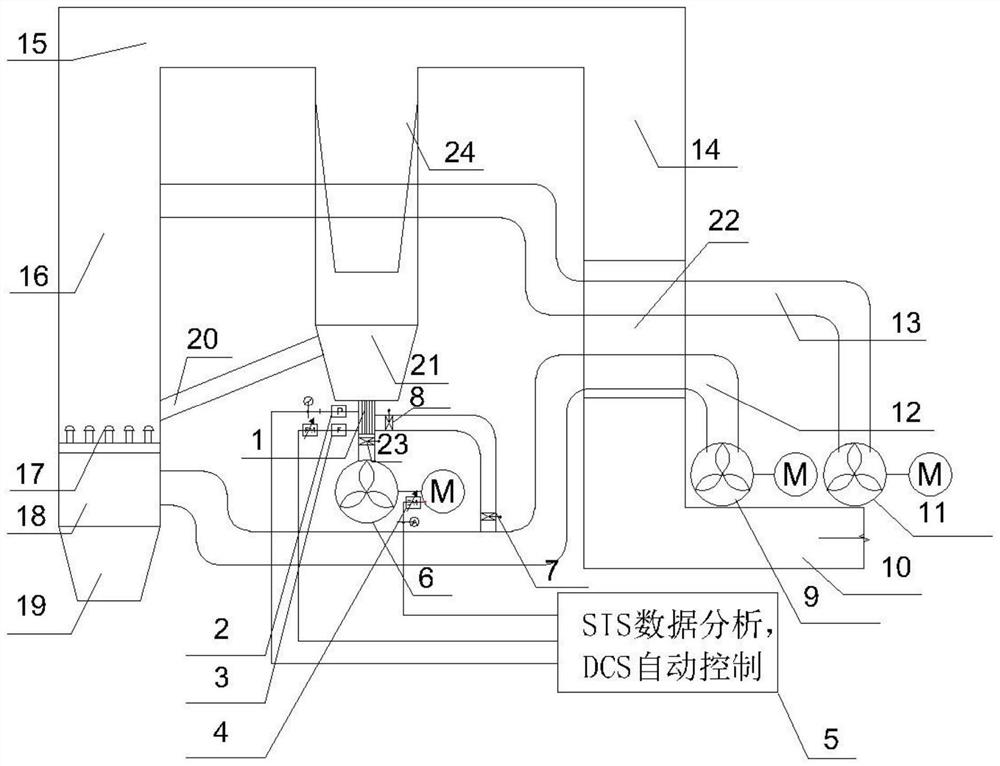

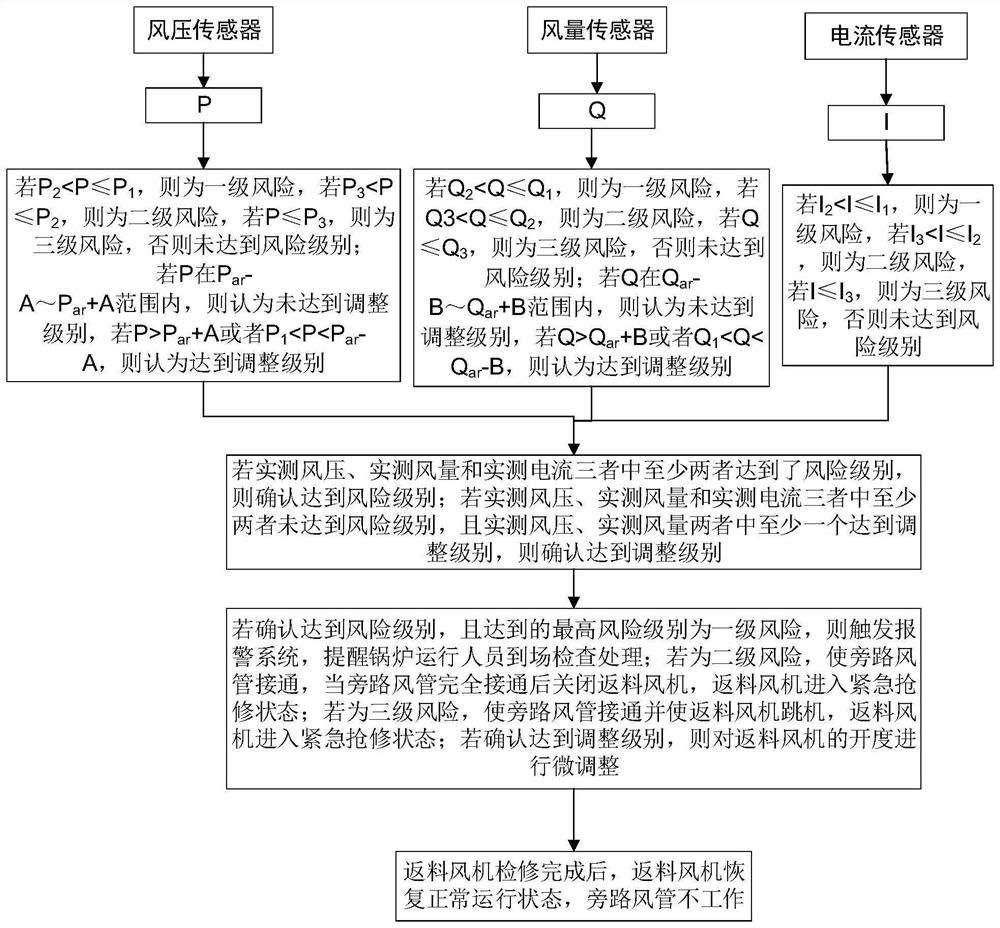

[0108] (1) if figure 1 As shown, a pair of air volume sensors 2 and air pressure sensors 3 are respectively arranged at the air inlet 1 of the feeder, and a pair of current sensors 4 are connected at the outlet of the return fan motor busbar; the above air volume sensors, wind pressure sensors, and current The real-time monitoring data of the sensor is uploaded to the automatic control system 8 of the boiler return system.

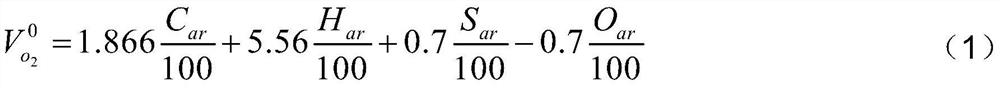

[0109] (2) The SIS system calculates the theoretical calculation formulas of air volume and air pressure:

[0110] 1) Theoretical air volume

[0111] 2) Theoretical wind pressure

[0112] (3) The warning value, switching value, and tripping value that must be satisfied for the safe operation of the boiler in this embodiment are shown in Table 2;

[0113] Pre-warning value, switching value and tripping value preset in the embodiment of table 2

[0114]

[0115] (4) After this embodiment was put into operation, comparatively good effect was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com