Building steel structure convenient to assemble

A steel structure and construction technology, applied in the direction of building components, building structures, buildings, etc., can solve the problems of increasing assembly difficulty and reducing work efficiency, and achieve the effects of reducing assembly difficulty, improving work efficiency, and facilitating assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

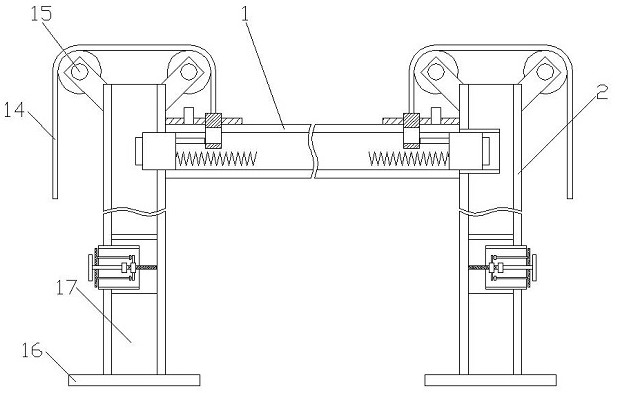

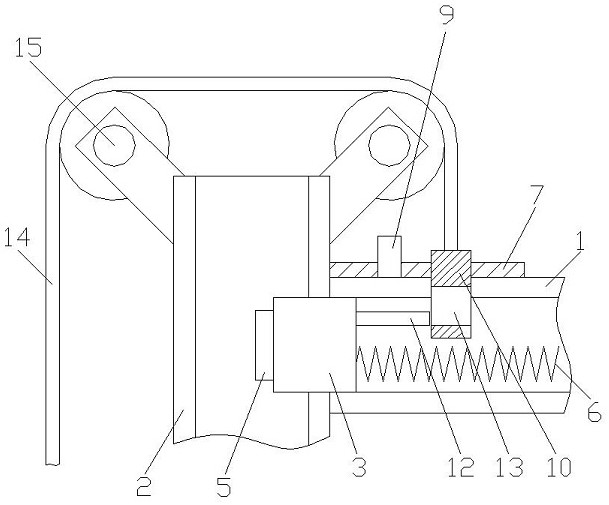

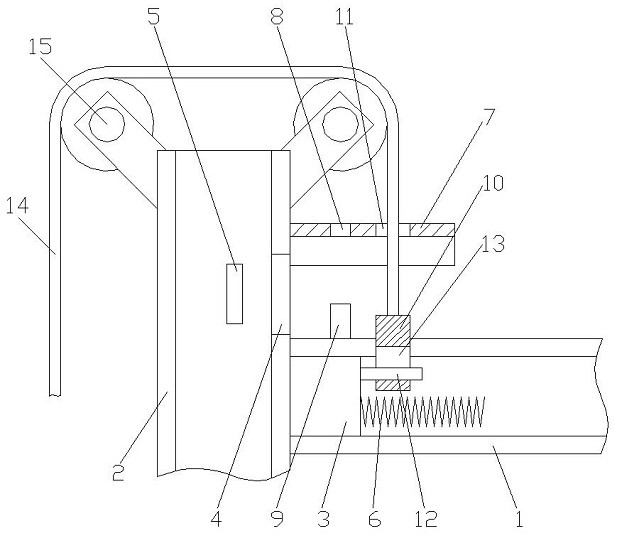

[0020] Such as Figure 1-4 As shown, a building steel structure that is easy to assemble in this embodiment includes a connecting pipe 1 and two supporting pipes 2, the connection is arranged horizontally, and the two supporting pipes 2 are vertically arranged at both ends of the connecting pipe 1 , the two support tubes 2 are provided with connecting mechanisms;

[0021] The connection mechanism includes a locking rod 3, a locking hole 4 and a traction assembly, the locking hole 4 and the locking rod 3 are coaxially arranged with the connecting pipe 1, and the locking hole 4 is arranged on the support pipe 2 , the locking rod 3 moves through the locking hole 4, the inner wall of the support tube 2 is fixed with a limit block 5, the limit block 5 is made of rubber, and the limit block 5 and the locking rod 3, the other end of the locking rod 3 is connected to the inner wall of the support pipe 2 through a spring 6, the diameter of the locking hole 4 and the inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com