Electroplating liquid anti-leakage carrier and anti-leakage treatment process thereof

A treatment process and electroplating solution technology, applied in the direction of plating tanks, electrolytic components, electrolytic processes, etc., can solve problems such as ignoring root causes, plant growth hazards, treating symptoms but not root causes, and achieving easy system construction, strong mobility, and reduced damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

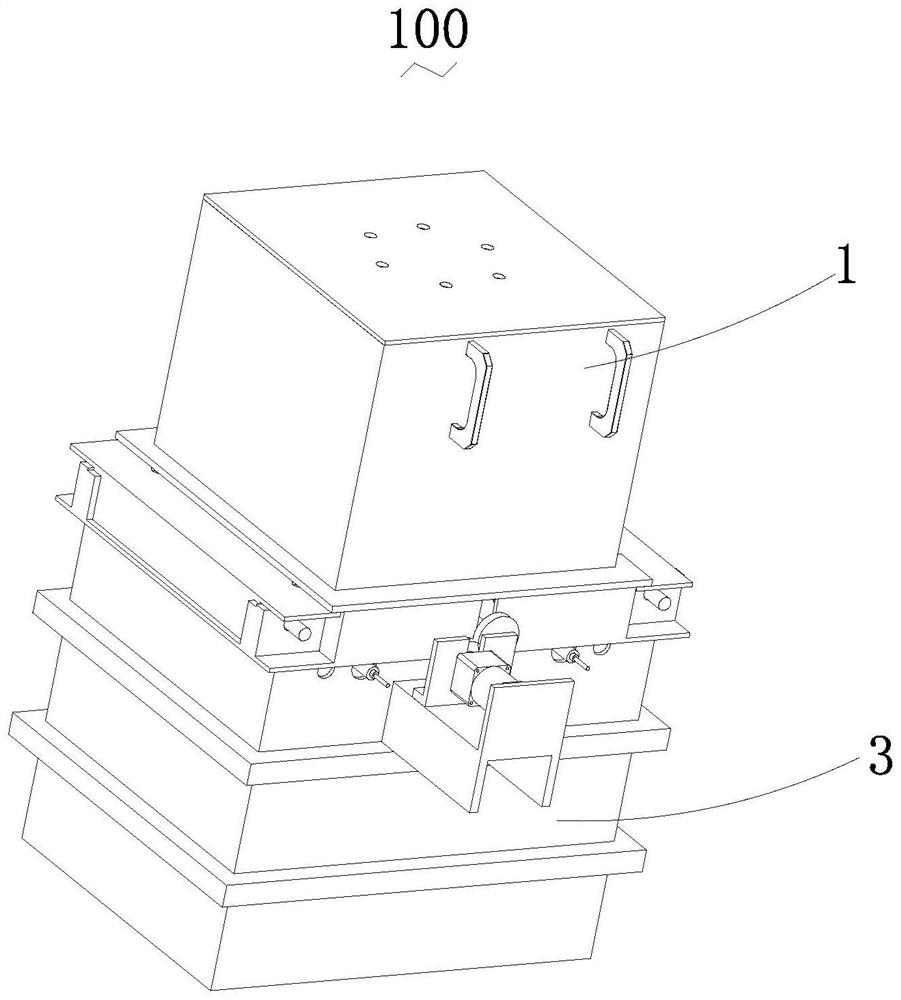

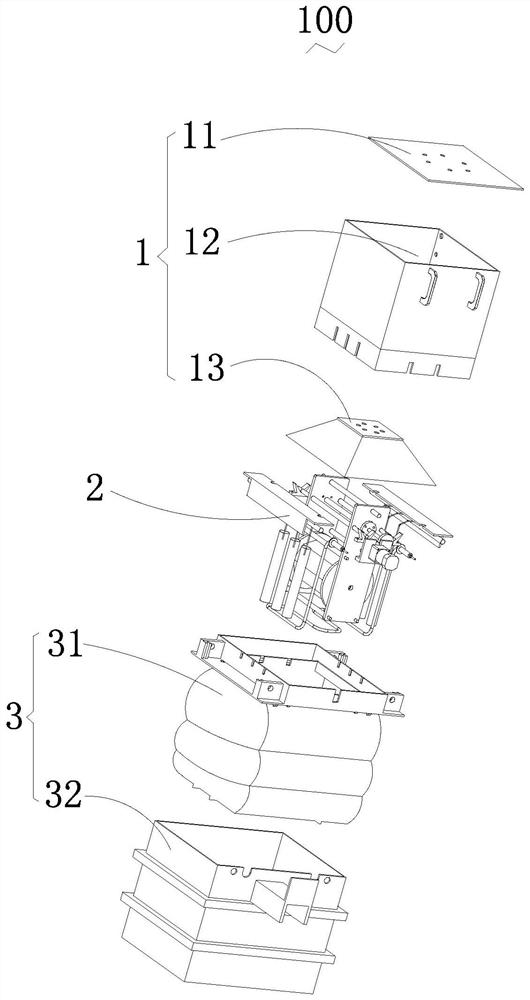

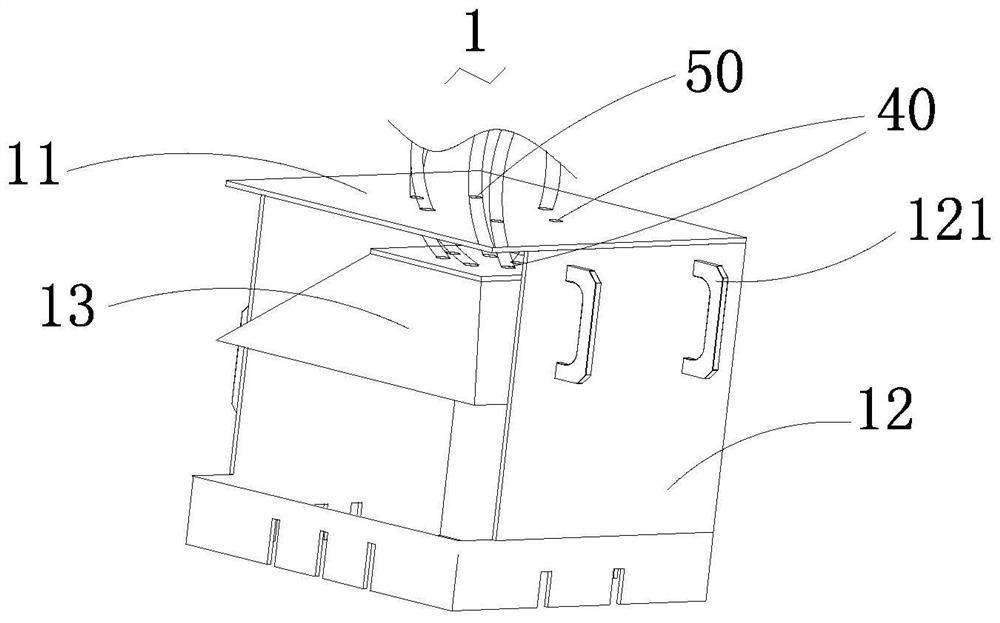

[0042] Embodiment 1 provided by the present invention mainly provides the anti-leakage carrier for electroplating solution, as well as the included mechanisms and their positional relationship and functions:

[0043] The electroplating solution leakage prevention carrier 100 includes an upper chamber cover 1 and a lower chamber groove 3, the upper chamber cover 1 and the lower chamber groove 3 can be covered to form a space, the space includes an electroplating mechanism 2, and the The anti-leakage carrier of the electroplating solution is also provided with a controller (not shown in the figure). The controller can be an industrial computer or a PLC, which can be debugged through an external connection to a host computer. All mechanical actions described below in the present invention are performed through the controller Execution, since the controller is a common technical feature for those skilled in the art, the present invention does not specifically describe the controlle...

Embodiment 2

[0060] In order to better solve the above problems, Embodiment 2 provided by the present invention mainly provides the anti-leakage treatment process of the electroplating solution leakage prevention carrier; based on the structural characteristics and connection relationship of the electroplating solution leakage prevention carrier described in Embodiment 1 Above, the anti-leakage treatment process of the electroplating solution anti-leakage carrier includes the following steps:

[0061] Step S1: Provide an upper chamber cover and a lower chamber groove, the upper chamber cover and the lower chamber groove can be covered to form a space, provide an air bag and set it on the upper chamber cover and the lower chamber gap in the groove;

[0062] Step S2: During the working state, use the space as the electroplating reaction tank and input the electroplating solution, inflate and expand the air bag to close the gap between the upper chamber cover and the lower chamber tank, and sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com