Whole-plant water network monitoring device for thermal power plant

A technology for thermal power plants and monitoring devices, applied in water/sewage treatment, water/sludge/sewage treatment, control/manipulation systems, etc., can solve the problems of increasing the possibility of accidents, increasing water consumption and drug consumption, and reducing water body self-control. Purification ability and other issues, to achieve the effect of improving self-purification ability, reducing the demand for drug dosage, and improving conservation awareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

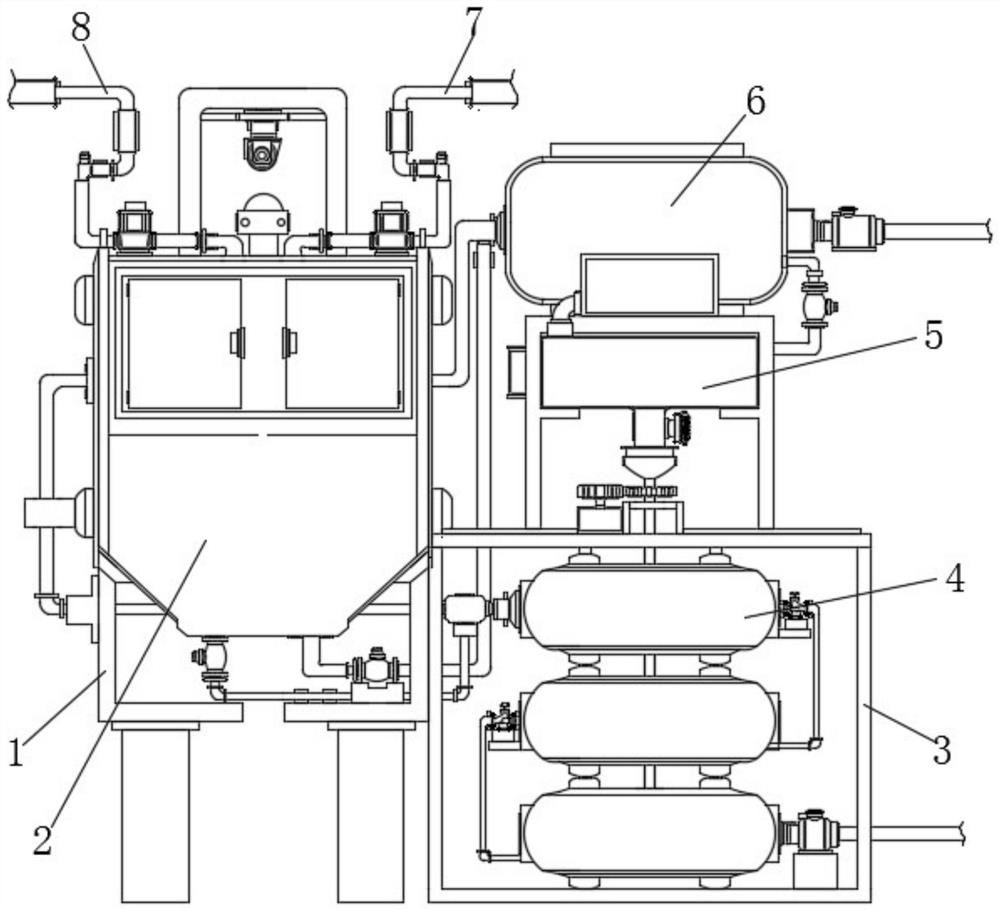

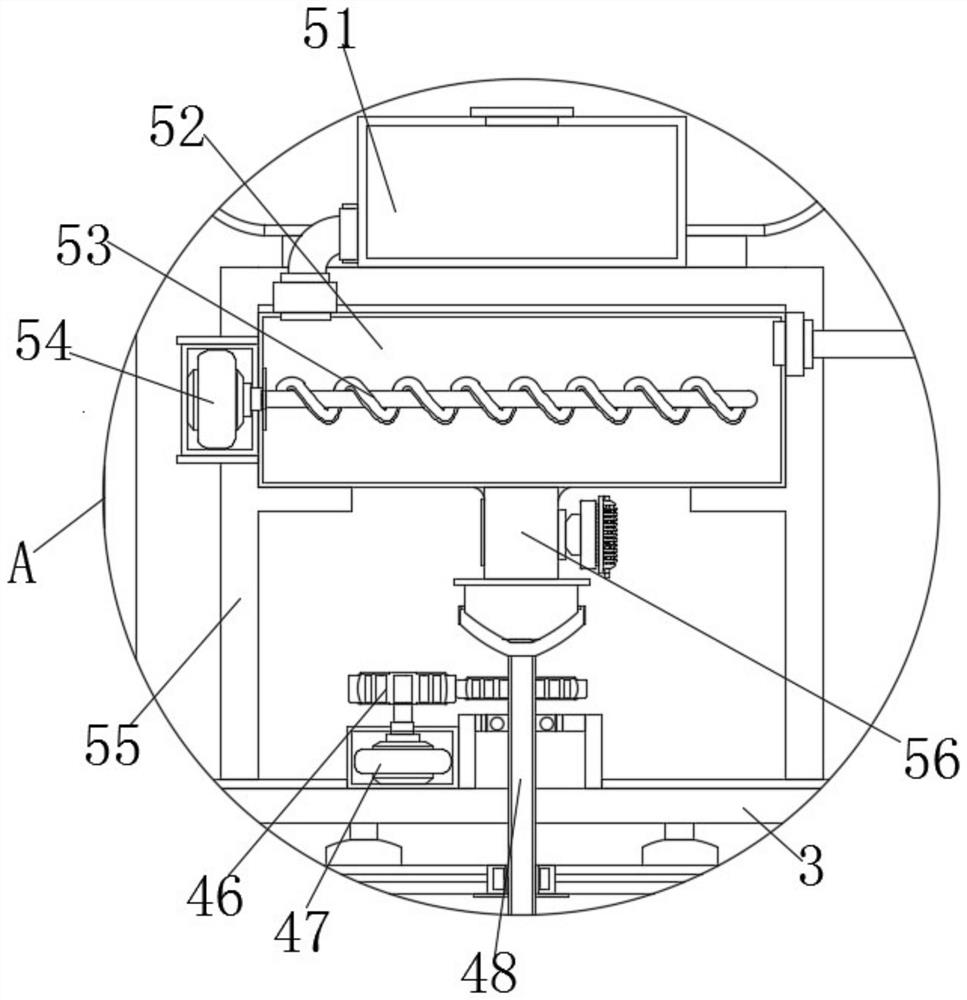

[0076] Example 1, such as Figure 1-5 As shown, in order to save water, reduce external discharge and pollution problems, it is necessary to measure the various water consumption, water intake, drainage and water consumption of thermal power plants, find out the water use status and the balance relationship between water departments, and reasonably analyze and evaluate the water consumption level of thermal power plants , to find out the water-saving potential, formulate practical water-saving measures and plans, make the water consumption and water-saving management level of thermal power plants more reasonable and scientific, reduce water consumption, improve water-saving level, and the health of pipelines and equipment in the water network also needs attention If the sub-health state of pipelines or equipment can be found in time, it will help to purchase spare parts in advance, arrange maintenance plans, and avoid losses after accidents, or even shut down. Using the monitor...

Embodiment 2

[0077] Example 2, such as Image 6 As shown, the system consists of two parts: basic monitoring equipment and software application platform. The basic monitoring equipment includes the collection and storage of related data signals of all water and sewage treatment systems, including water volume, water pressure, water temperature, water quality, equipment current, For voltage, electricity, speed, vibration, water quality, dosage, etc., interface acquisition programs are written according to relevant protocols to collect data and store them in the database. Software platform applications include 3D portals, full water balance maps, online monitoring of various systems, and water analysis of the entire plant , water analysis, evaluation and optimization of each system, water balance test, sewage treatment supervision, waste water discharge supervision, equipment status, water network equipment health analysis, water network pipeline health analysis, digital files, report system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com