Protection gas control device

A shielding gas and control device technology, which is applied in the flow control of electric devices, manufacturing tools, arc welding equipment, etc., can solve the problems of wasting shielding gas, electricity or time, and complicated gas flow, so as to improve the awareness of saving and easy to confirm or adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

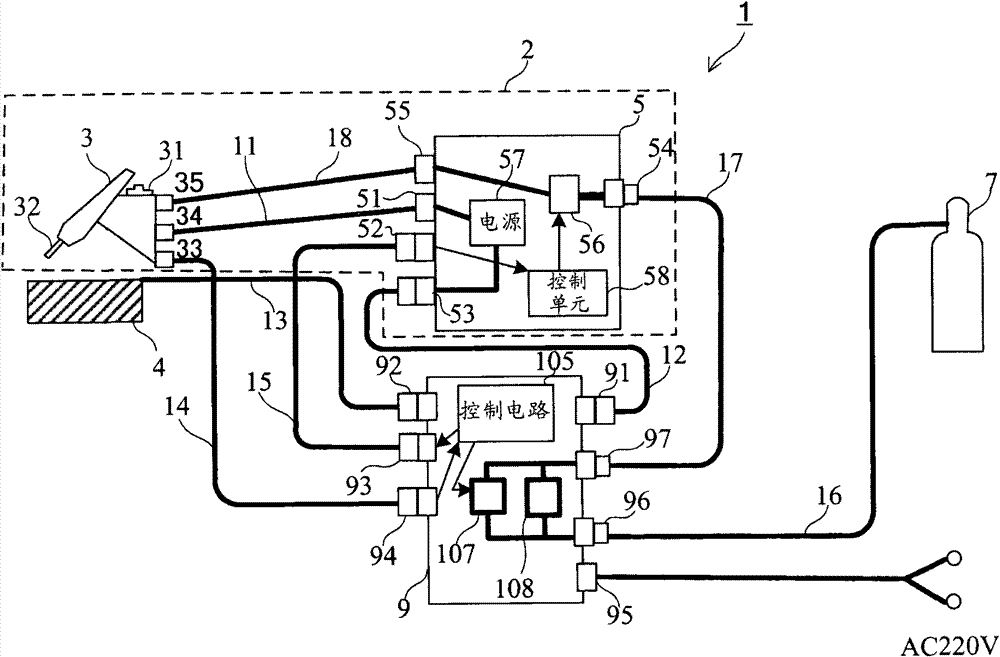

[0030] The present invention is applied to a welding machine that performs gas-shielded arc welding and uses an inert gas as a shielding gas, and a gas control device connected to the welding machine. In the following description, an apparatus for performing TIG welding will be described as an example.

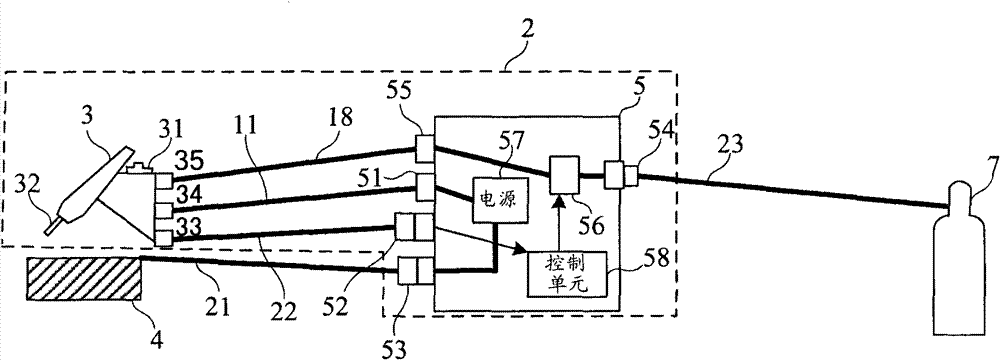

[0031] figure 2 It is a connection diagram of a welding system provided with a shielding gas control device according to an embodiment of the present invention.

[0032] Welding system 1 is in Figure 1A A system in which a shielding gas control device (hereinafter, simply referred to as a gas control device) 9 is connected to the welding device 2 shown. The welding system 1 includes: a welding device 2 composed of a welding torch 3 and a welding machine 5 ; a gas cylinder 7 serving as an inert gas supply source; and a gas control device 9 .

[0033] The power supply terminal 51 of the welding machine 5 and the terminal 34 of the torch switch are connected by the cable 11 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com