Preparation method and application of fluorinated graphene with high thermal stability, insulation and high thermal conductivity

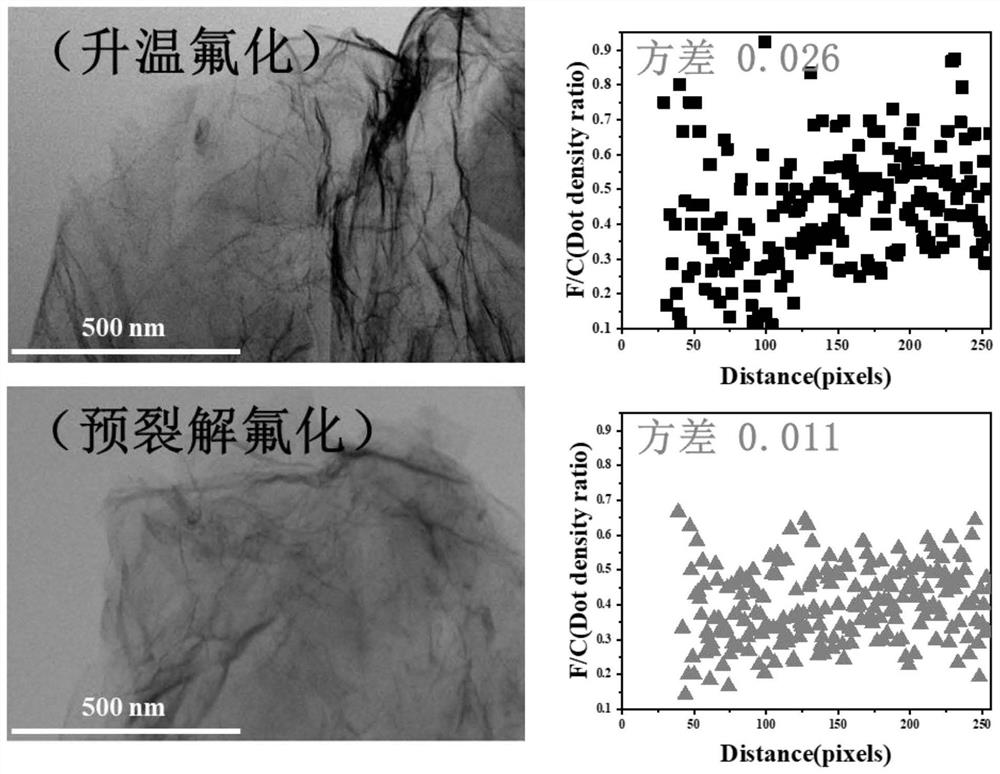

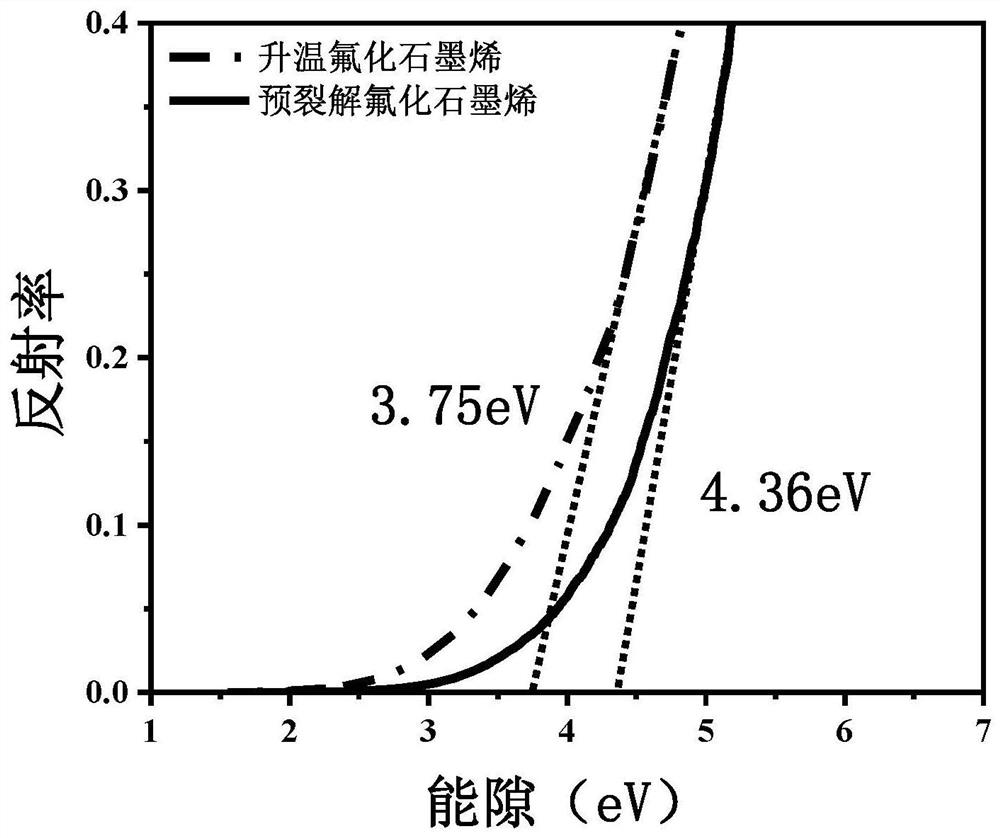

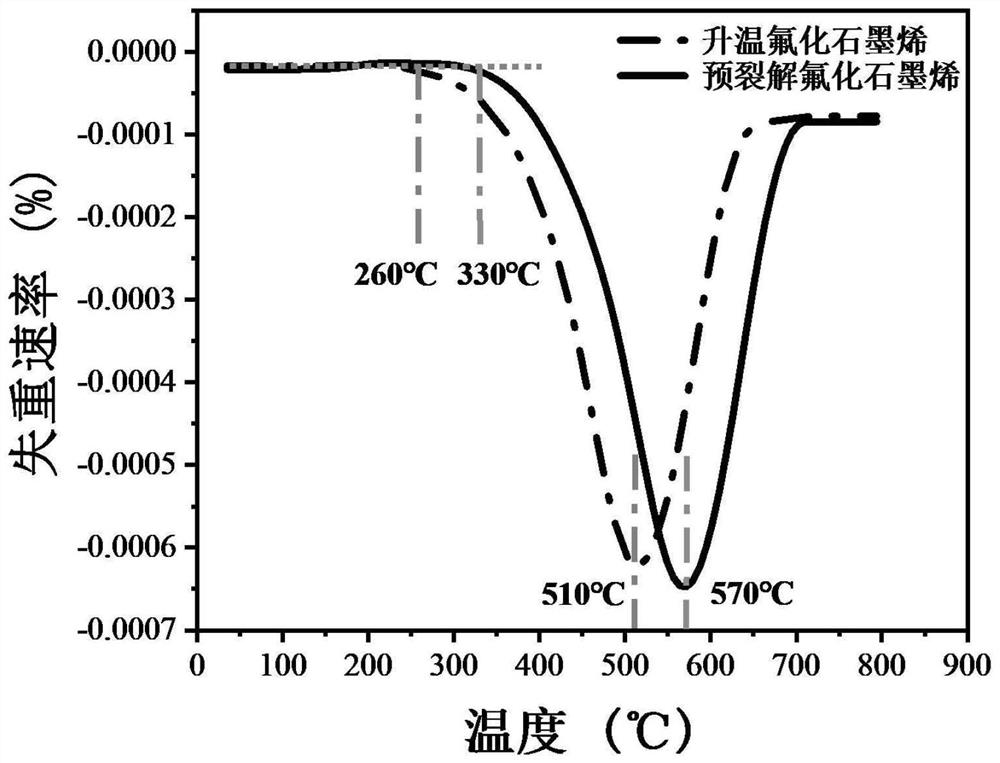

A fluorinated graphene, high thermal stability technology, applied in the direction of graphene, chemical instruments and methods, carbon compounds, etc., can solve the problems of poor thermal stability, uneven distribution of fluorine, and poor thermal conductivity. It is easy to put into production in batches, the reaction is thorough, and the production efficiency is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the fluorinated graphene with high thermal stability, insulation and high thermal conductivity provided by the invention comprises the following steps:

[0035] 1) Place the dried graphene in the fluorination kettle, vacuumize the inside of the fluorination kettle first, then pass nitrogen gas in and pump it out for multiple replacement treatments, and then raise the temperature of the fluorination kettle to 140-260°C; the replacement The treatment is to replace the air in the fluorination kettle by vacuumizing first, then introducing nitrogen and pumping out nitrogen. The multiple replacement processes here are to improve the replacement effect, and in specific implementation, the multiple times can be 2-5 times.

[0036] 2) The buffer kettle is subjected to the same replacement treatment in step 1) for many times, and then heated to the same temperature as the fluorination kettle in step 1); the replacement treatment method of this step is the ...

Embodiment 1

[0042] Put the graphene in the fluorination kettle, replace the air in the fluorination kettle and the buffer kettle with nitrogen three times, and then raise the temperature of the fluorination kettle and the buffer kettle to 140°C;

[0043] Pass the fluorination reaction mixed gas with the fluorine concentration of 20% mixed by fluorine gas and nitrogen gas into the buffer tank, and keep it for 10 minutes for thermal pre-dissociation;

[0044] Pass the fluorination reaction mixed gas after thermal pre-dissociation into the fluorination kettle until the pressure is 50Kpa, and perform the fluorination reaction for 1 hour. After the fluorination kettle is naturally cooled, take out the sample to obtain fluorinated graphene.

[0045] The sample of this embodiment is tested: the fluorine-carbon atomic ratio of the fluorinated graphene is 0.61 by XPS, and the thermal weight loss peak temperature of the TGA test is 576 ° C. The fluorinated graphene is applied to the cellulose compos...

Embodiment 2

[0047] Put the graphene in the fluorination kettle, replace the air in the fluorination kettle and the buffer kettle with nitrogen three times, then raise the temperature of both the fluorination kettle and the buffer kettle to 200°C;

[0048] Pass the fluorination reaction mixed gas with fluorine gas concentration of 10% mixed with fluorine gas and nitrogen gas into the buffer tank, and keep it for 10 minutes for thermal pre-dissociation;

[0049] Pass the fluorination reaction mixed gas after thermal pre-dissociation into the fluorination kettle until the pressure is 80Kpa, and perform the fluorination reaction for 1 hour. After the fluorination kettle is naturally cooled, take out the sample to obtain fluorinated graphene.

[0050] The sample of this embodiment is tested: the fluorine-to-carbon atomic ratio of the fluorinated graphene is 0.55 by XPS test, and the thermal weight loss peak temperature of the TGA test is 565 ° C. The fluorinated graphene is applied to the cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com