Double-gantry type high-rigidity ram machining device

A processing device and high-rigidity technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of increased motor speed, long duration, large stator current, etc., to reduce response time and prevent burning Damaged coils, the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

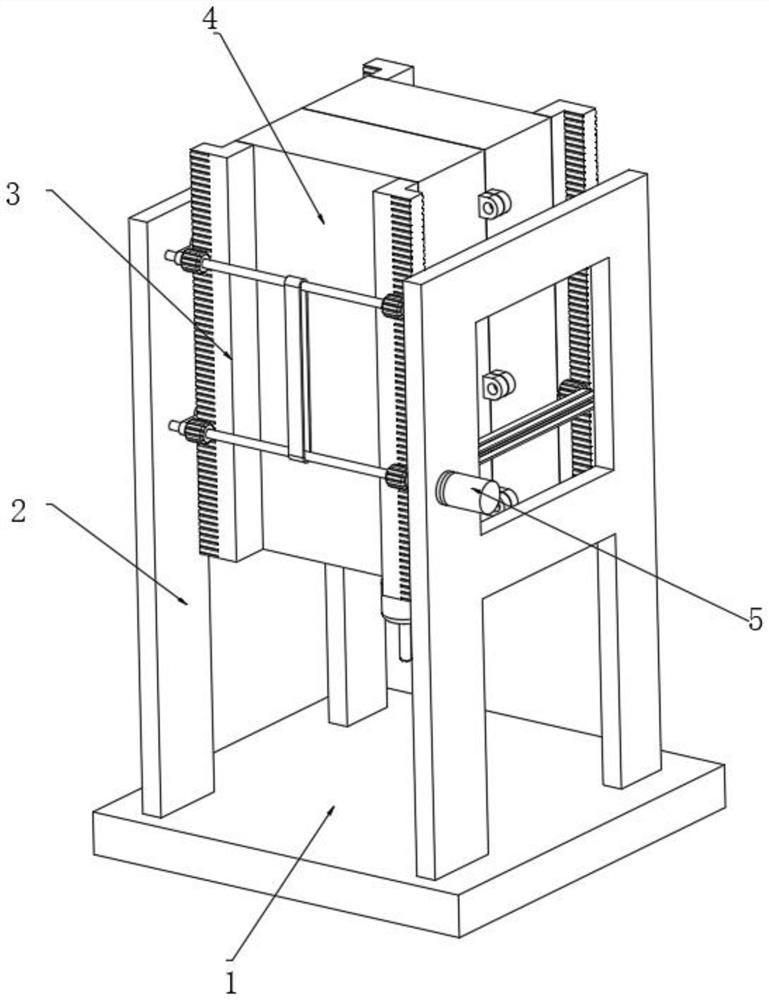

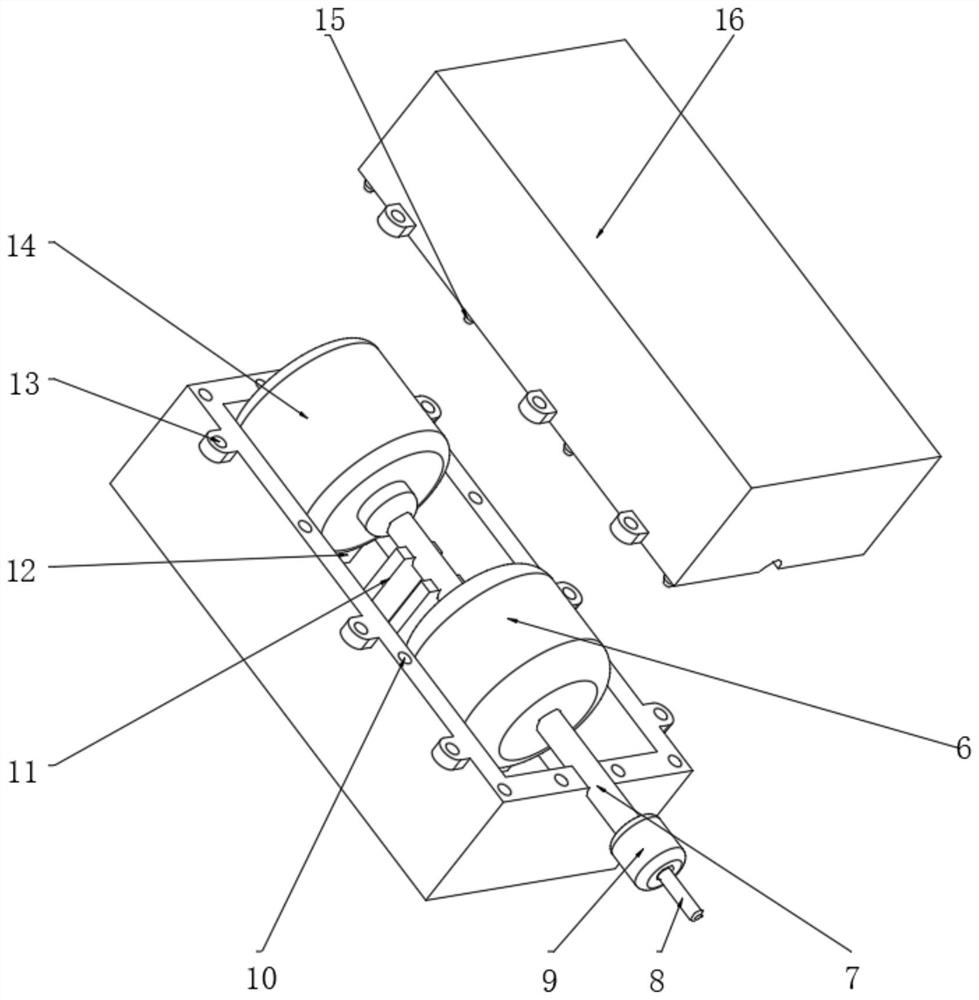

[0042] A double gantry type high rigidity ram processing device, such as Figure 1-8 As shown, it includes a workbench 1, two gantry frames 2 for support, a ram 4 connected to the inside of the gantry frame 2 through two sets of linear lifting parts 3 and a ram 4 linearly slidingly connected to the inside of the gantry frame 2, and a processing part arranged inside the ram 4. The processing part includes a spindle motor 14 for power supply, a spindle 7 for output power, a tool 8 coaxially connected to the spindle 7 through a clamp 9 and used for processing, and a buffer 6 for connecting the spindle motor 14 and the spindle 7 .

[0043] In order to solve the problem of instantaneous load at startup; Figure 4 As shown, the buffer 6 includes a driving casing 25 and a driven casing 27 that are connected to each other in a sealed rotation through a sealing swivel 26 and filled with oil, and the outer walls of the driving casing 25 and the driven casing 27 are welded. For connect...

Embodiment 2

[0049] A double gantry type high rigidity ram processing device, such as figure 2 As shown, in order to solve the problem of convenience; this embodiment makes the following improvements on the basis of Embodiment 1: the ram 4 includes two half-shells 16 fixed to each other by flange ears 13, and one of the half-shells 16 The inner wall of the housing 16 is provided with a limit hole 10, and the outer wall of the other half shell 16 is welded with a limit post 15 that matches the limit hole 10; by dividing the ram 4 into two half shells 16 , on the one hand, it makes installation and disassembly more convenient, on the other hand, they are all cavity type, and their own weight is low, so that the elastic deformation caused by their own weight is small, and the rigidity is indirectly increased, and because the limit post 15 and the limit hole 10 The cooperation can limit the relative position of the two half-shells 16, and the limit positions are all in surface contact, which ...

Embodiment 3

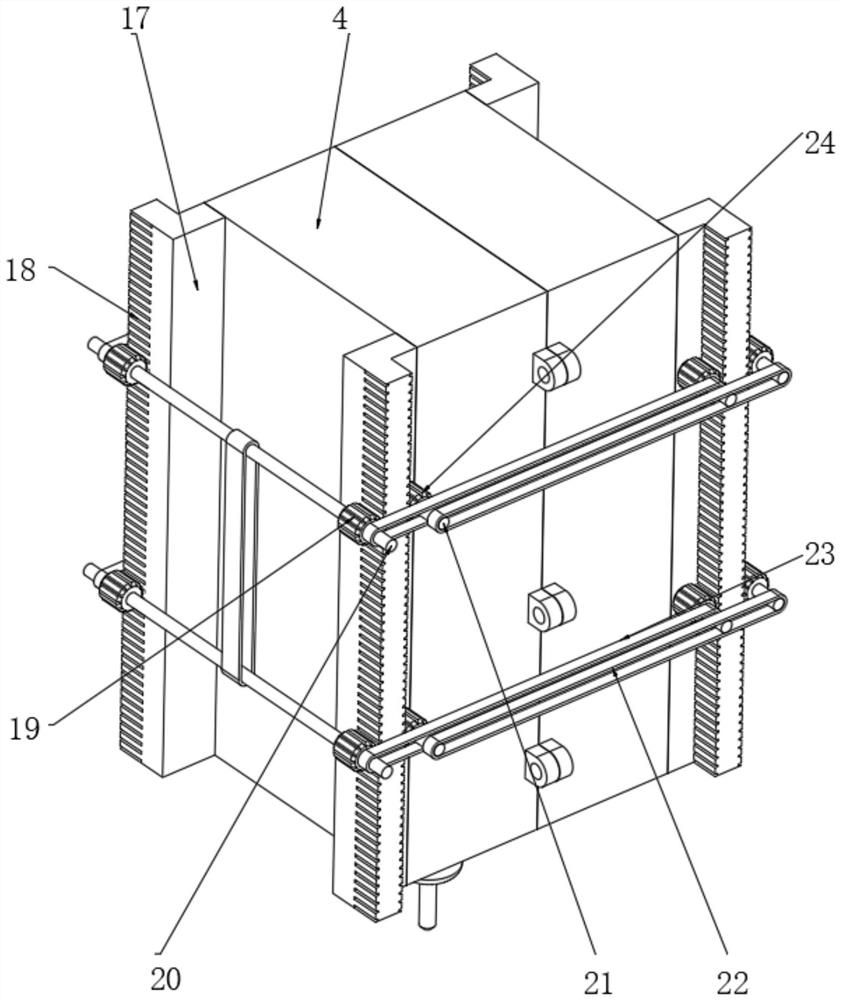

[0053] A double gantry type high rigidity ram processing device, such as figure 2 As shown, in order to solve the problem of accuracy; this embodiment makes the following improvements on the basis of Embodiments 1 and 2: the linear lifting part 3 includes a support plate 17 welded to the four corners of the ram 4 outer walls and a support plate 17 provided through the support plate Teeth 18 are meshed with gear one 19 and gear two 24 on both sides of support plate 17. The gear one 19 located on the same side and at the same height is connected by shaft one 20, and is connected to the gantry 2 through shaft one 20 in rotation. The inner wall, the gear two 24 is connected to the inner wall of the gantry 2 through the shaft two 21, and the shaft one 20 and the shaft two 21 on the same side of the support plate 17 are respectively driven and matched with the synchronization component two 23 through the synchronization component one 22. In the embodiment, the specific types of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com