Lithium ion battery electrolyte

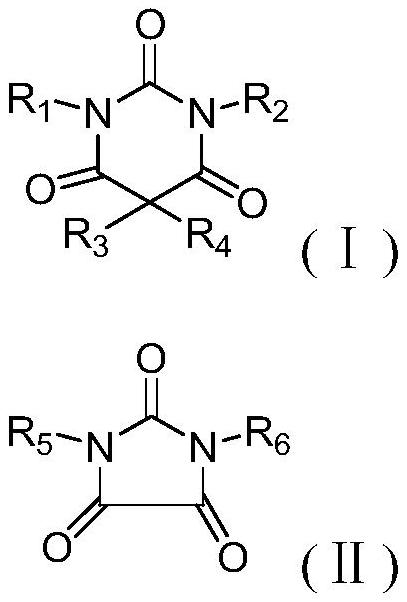

A lithium-ion battery and electrolyte technology, which is applied in the field of lithium-ion batteries and additive synthesis, can solve the problems affecting the cycle characteristics of lithium-ion secondary batteries, the combined use of additives that are not mentioned, and the increase in the impedance of battery pole pieces, etc., to achieve improved high performance. Low-temperature cycle performance, improvement of low-temperature discharge capacity retention rate and rate discharge capacity retention rate, and the effect of reducing film resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0046] Synthesis Example 1: Synthesis of Compound Ⅰ-1

[0047] Add 156.14g (1mol) of 5,5-dimethylmalonylurea and 1000mL of N,N-dimethylformamide into a 2L three-port reactor, add 83.92g (2.0mol) of lithium hydroxide monohydrate, and 241.96 g (2.0 mol) of 3-bromopropene were added dropwise. After adding the raw materials, stir for 30 minutes, and react at 60°C for 6 hours. LC-Ms detects that the reaction of the raw materials is complete, and the reaction solution is depressurized to recover N,N-dimethylformamide. Cool the kettle residue to room temperature, add 1000mL of water, add 2000mL of ethyl acetate for extraction and stirring, then enter the oil-water separator for separation. The organic phase was rectified under reduced pressure to obtain a crude product, and 3A molecular sieves were used to remove water to 50 ppm, and 177.20 g of a colorless liquid was obtained through rectification under reduced pressure twice, with a GC purity of 99.91% and a yield of 75%.

[004...

Synthetic example 2

[0049] Synthesis Example 2: Synthesis of Compound Ⅰ-2

[0050] Add 128.09g (1.0mol) of malonylurea and 1200mL of N,N-dimethylformamide into a 2L three-port reactor, add 209.8g (5.0mol) of lithium hydroxide monohydrate, and drop 604.90g (5.0 mol) 3-bromopropene. After adding the raw materials, stir for 30 minutes, and react at 100°C for 24 hours. LC-Ms detects that the reaction of the raw materials is complete, and the reaction solution is depressurized to recover N,N-dimethylformamide. Cool the kettle residue to room temperature, add 1000mL of water, add 2000mL of ethyl acetate for extraction and stirring, then enter the oil-water separator for separation. The organic phase was rectified under reduced pressure to obtain the crude product, and 3A molecular sieve was used to remove water to 50 ppm. After two times of rectified under reduced pressure, 259.51 g of colorless liquid was obtained. The GC purity was 99.92%, and the yield was 90%.

[0051]

Synthetic example 3

[0052] Synthesis Example 3: Synthesis of Compound Ⅰ-3

[0053] Add 164.07g (1.0mol) of 5,5-difluoromalonylurea and 1000mL of N,N-dimethylformamide into a 2L three-port reactor, add 104.90g (2.5mol) of lithium hydroxide monohydrate, 231.30 g (2.5 mol) of 2-(chloromethyl)oxirane were added dropwise. After adding the raw materials, stir for 30 minutes, and react at 80°C for 16 hours. LC-Ms detects that the reaction of the raw materials is complete, and the reaction solution is depressurized to recover N,N-dimethylformamide. Cool the kettle residue to room temperature, add 1000mL of water, add 2000mL of 1,2-dichloroethane and stir, then enter the oil-water separator for separation. The organic phase was crystallized under reduced pressure to obtain a crude solid. The crude product was dissolved in 1,2-dichloroethane, and the water was removed to 50 ppm by using 3A molecular sieves. After secondary crystallization and purification, a white solid was obtained. The HPLC purity was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com