System and method for cooling slurry

A mud and cooling cavity technology, applied in the field of oil and gas well drilling, can solve the problems of large site conditions and environmental impact, affecting the normal use of measuring instruments, reducing the service life of downhole tools, etc., to achieve improved bottom temperature, good application effect and economical benefits, effects of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

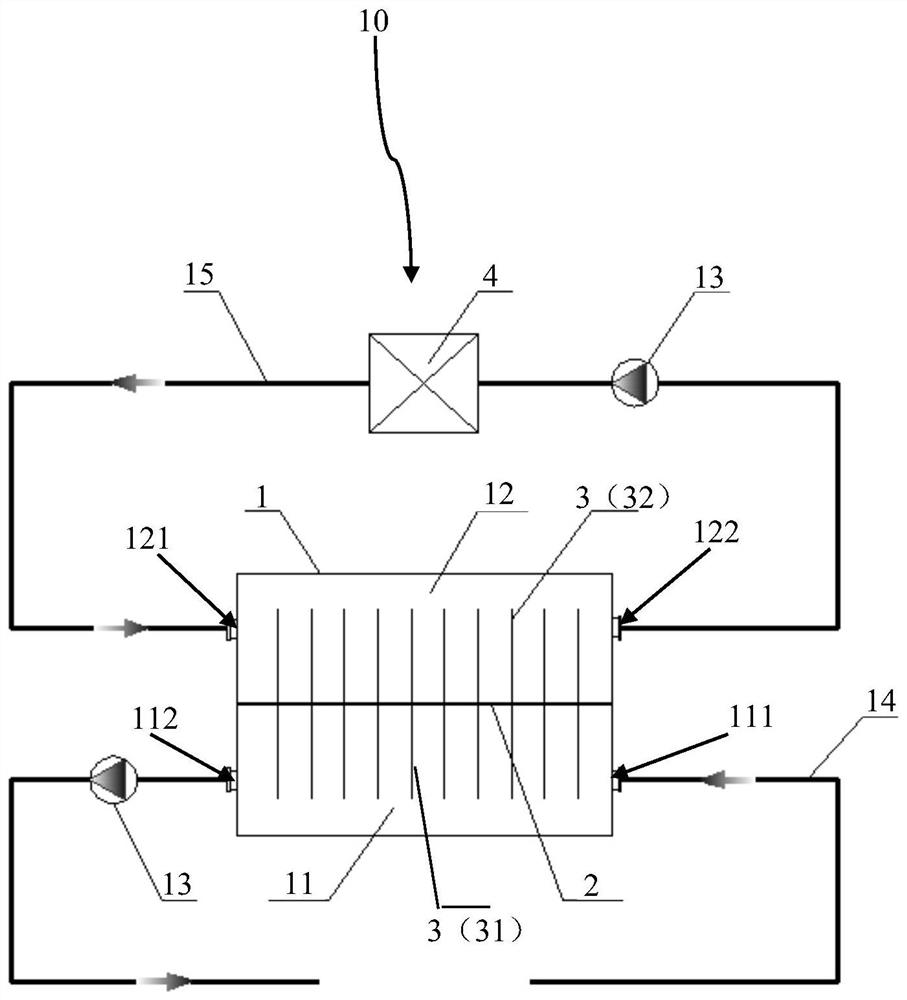

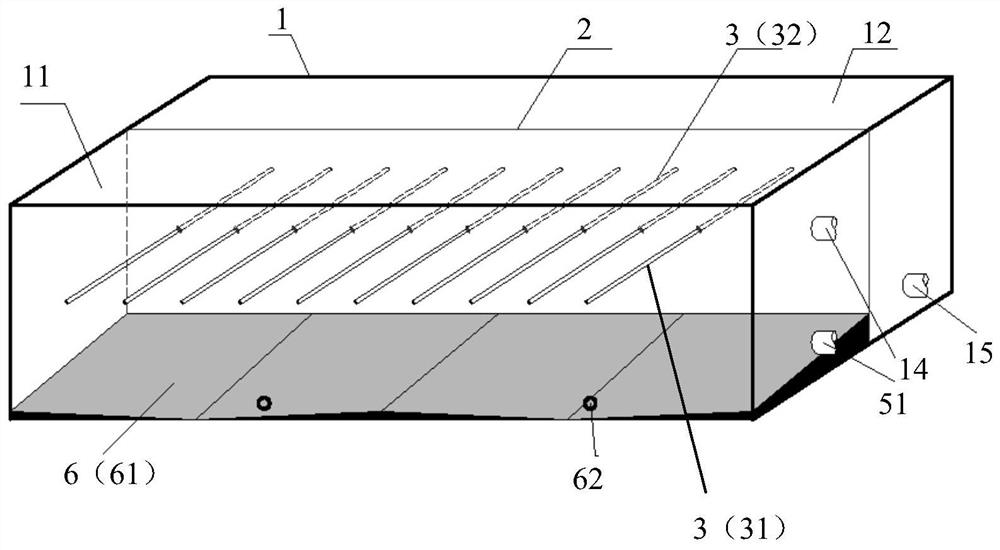

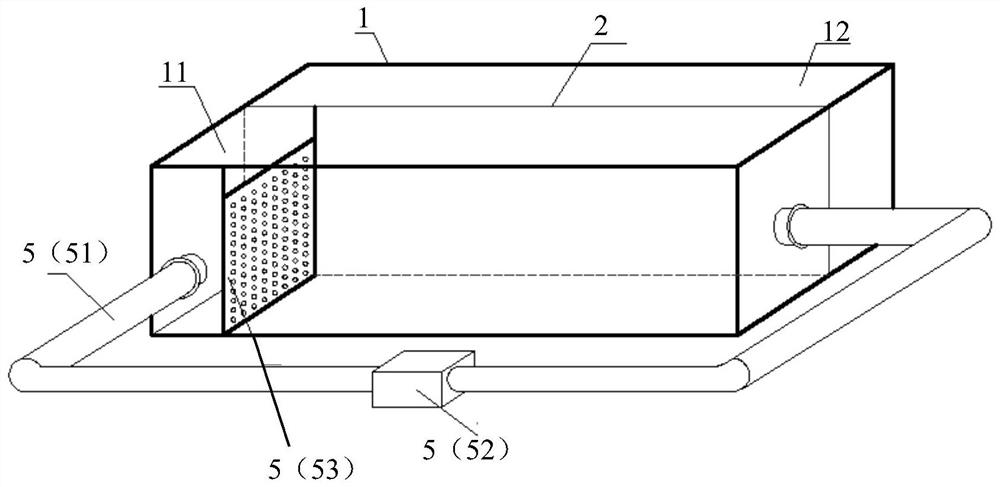

[0037] Such as figure 1 As shown, the system 10 for mud cooling according to the embodiment of the present invention includes a mud cooling tank 1 . Wherein, the mud cooling tank 1 is provided with a partition 2, and the partition 2 is provided with evenly spaced heat pipes 3, and the partition 2 separates the mud cooling tank 1 into a cooling chamber 11 and a heating chamber 12, and the evaporation section 31 of the heat pipe 3 Located in the cooling chamber 11 , the condensation section 32 of the heat pipe 3 is located in the heating chamber 12 . One side of the cooling chamber 11 is provided with a mud inlet 111 for mud to flow in, and the other side of the cooling chamber 11 is provided with a mud outlet 112 for mud to flow out. The same side of the heating chamber 12 as the mud outlet 112 is provided with a cooling water inlet 121 for cooling water to flow in, and the other side of the heating chamber 12 is provided with a cooling water outlet 122 for cooling water to fl...

Embodiment 2

[0047] The method for cooling mud according to the embodiment of the present invention is implemented by using the above-mentioned system 10, and specifically includes the following steps: S01. Install the above-mentioned system. S02. Send the high-temperature mud into the cooling chamber through the mud inlet, contact the evaporation section of the heat pipe, and transfer heat to the low-temperature cooling water flowing from the cooling water inlet into the heating chamber and contacting the condensation section of the heat pipe for cooling. The cooled mud passes through The mud flows out from the outlet and enters the drilling fluid circulation system at the well site. S03. The heated cooling water flows out through the cooling water outlet, and is transported to the cooling device by the cooling water pipeline of the circulating pump well. After evaporative cooling is completed, it flows back into the heating chamber of the mud cooling tank. S04, start the self-circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com