Hydrogen detector based on elastic optical fiber

A technology of optical detectors and detectors, applied in color/spectral characteristic measurement, instruments, measuring devices, etc., can solve the problems of high manufacturing process requirements, thinning optical fibers, etc., achieve high sensitivity and ensure firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

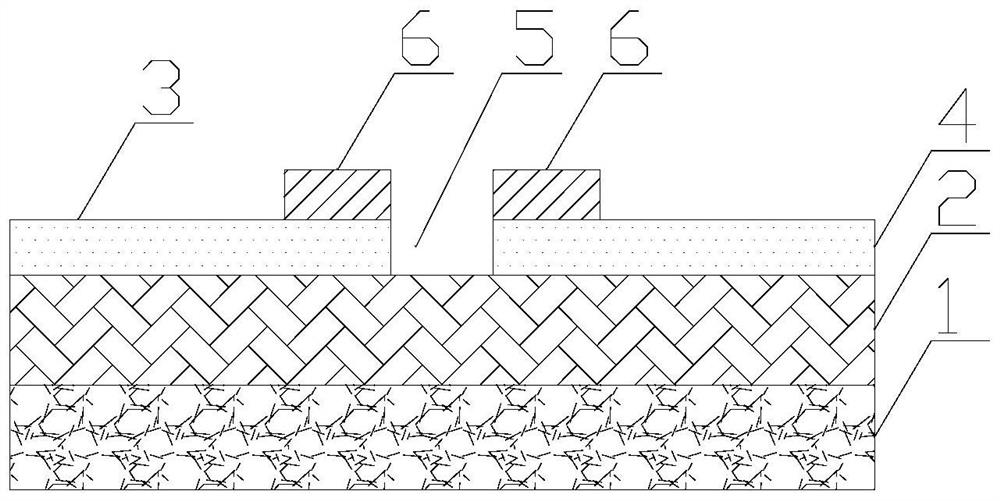

[0024] The invention provides a hydrogen detector based on elastic optical fiber. The elastic optical fiber-based hydrogen detector includes a light source, a photodetector, a substrate 1 , an elastic layer 2 , a first elastic optical fiber 3 , a second elastic optical fiber 4 , and a palladium film 6 . Such as figure 1 As shown, the elastic layer 2 is placed on the substrate 1 . The material of the substrate 1 is not limited. The substrate 1 can be used for fixing, and a suitable material for the substrate 1 is selected so as to fix the device on a certain component. The material of the elastic layer 2 is PMMA, and the thickness of the elastic layer 2 is greater than 100 microns, so that the elastic layer 2 has higher elasticity. The first elastic optical fiber 3 and the second elastic optical fiber 4 are placed on the elastic layer 2 . The first elastic optical fiber 3 and the second elastic optical fiber 4 are plastic optical fibers. Plastic optical fiber is a type of ...

Embodiment 2

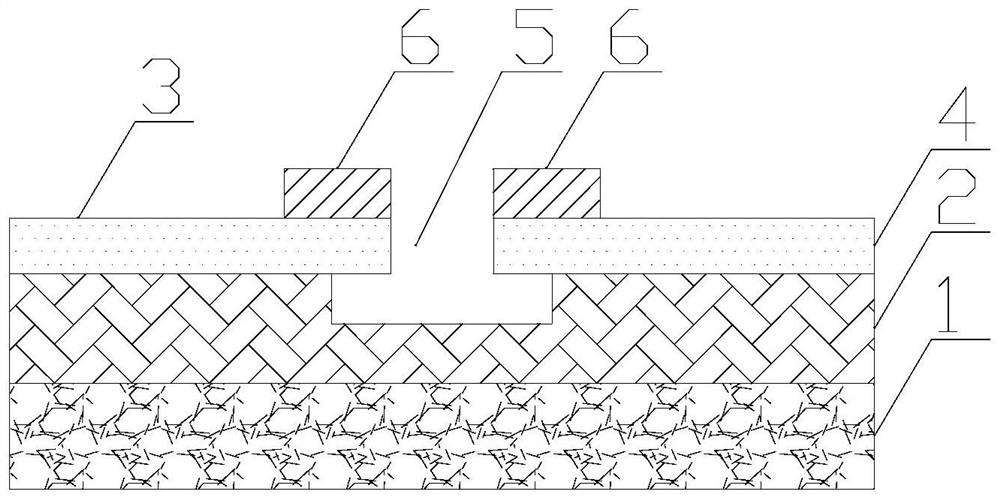

[0028] On the basis of Embodiment 1, the end surfaces of the first elastic optical fiber 3 and the second elastic optical fiber 4 are tapered. That is, the first elastic optical fiber 3 and the second elastic optical fiber 4 gradually become thinner along the direction from the first elastic optical fiber 3 to the gap 5 and along the direction from the second elastic optical fiber 4 to the gap 5 . The tapered end face reduces the relative area of the first elastic optical fiber 3 and the second elastic optical fiber 4, when the distance between the first elastic optical fiber 3 and the second elastic optical fiber 4 changes, the first elastic optical fiber 3 and the second elastic optical fiber The coupling characteristics between the fibers 4 change more. That is to say, the coupling characteristics or propagation characteristics of the first elastic optical fiber 3 to the second elastic optical fiber 4 depend more heavily on the distance between the two, so as to realize h...

Embodiment 3

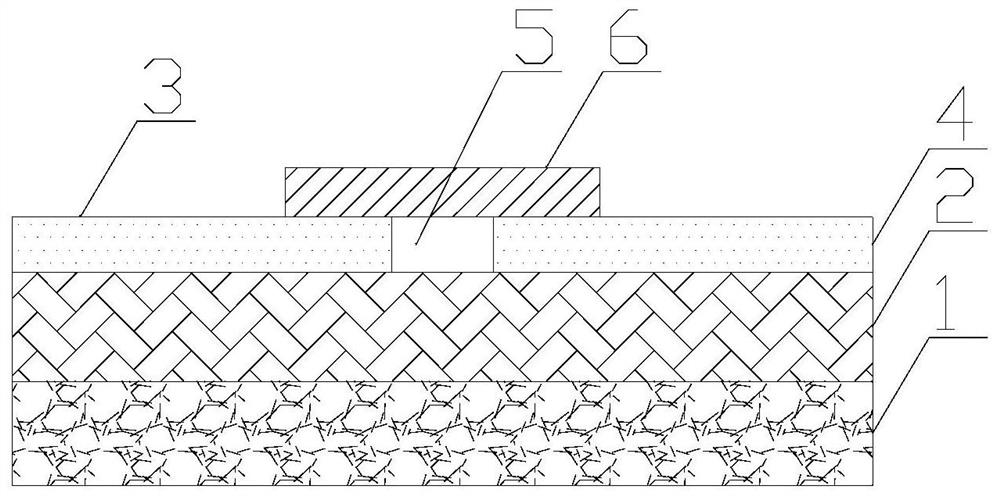

[0030]On the basis of Embodiment 2, at the gap 5 , a pit is provided on the surface of the elastic layer 2 , and the ends of the first elastic optical fiber 3 and the second elastic optical fiber 4 are suspended. When the ends of the first elastic optical fiber 3 and the second elastic optical fiber 4 are suspended, the ends of the first elastic optical fiber 3 and the end of the second elastic optical fiber 4 are no longer in contact with the elastic layer 2, reducing the size of the first elastic optical fiber 3 , the adhesion or force of the second elastic optical fiber 4 and the elastic layer 2, so that when the palladium membrane 6 expands, the first elastic optical fiber 3 and the second elastic optical fiber 4 expand more, and change the gap 5 more. Width, so as to achieve higher sensitivity hydrogen detection. Furthermore, the width of the pit is greater than the width of the palladium film 6 on the first elastic optical fiber 3 and the second elastic optical fiber 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com